The Science Behind PDC Bit Technology

Understanding the science behind Polycrystalline Jewel Penetrate Bits is significant to increasing in value their predominant execution in oil boring operations. At the heart of PDC bit innovation lies the inventive utilize of engineered jewel materials. These bits highlight a network body, regularly made of tungsten carbide, which gives a strong establishment for the cutting components. The cutting structure comprises of PDC cutters - manufactured precious stone plates fortified to tungsten carbide substrates. This special composition offers a few advantages:

Advanced Materials and Manufacturing

The polycrystalline diamond utilized in Polycrystalline Diamond Drill Bits is manufactured through a high-pressure, high-temperature (HPHT) process. This strategy produces a fabric with extraordinary hardness and wear resistance, outperforming that of characteristic jewels. The precious stone layer is at that point fortified to the tungsten carbide substrate utilizing advanced brazing strategies, guaranteeing a secure connection that can withstand the extraordinary conditions experienced amid drilling.

Cutting Mechanism

Unlike conventional roller cone bits that pulverize shake through a crushing activity, PDC bits utilize a shearing component. The precious stone cutters are organized on the bit confront in a particular design, permitting them to cut through shake arrangements productively. This shearing activity comes about in quicker entrance rates and decreased vitality utilization amid boring operations.

Thermal Stability

One of the key advancements in PDC bit technology is the development of thermally stable polycrystalline (TSP) diamond cutters. These cutters maintain their integrity at higher temperatures, allowing for improved performance in demanding drilling environments. The enhanced thermal stability also contributes to longer bit life and consistent cutting efficiency throughout the drilling process.

Cost-Efficiency: PDC vs Traditional Bits

When it comes to cost-efficiency in oil boring operations, Polycrystalline Precious stone Bore Bits offer critical focal points over conventional roller cone bits. Whereas the beginning speculation for PDC bits may be higher, their long-term benefits frequently result in considerable taken a toll reserve funds for boring companies. Let's investigate the key variables that contribute to the prevalent cost-efficiency of PDC bits:

Increased Rate of Penetration (ROP)

Polycrystalline Diamond Drill Bits (PDC bits) are renowned for their ability to achieve higher rates of penetration (ROP) compared to conventional bits. This increased ROP translates to faster drilling times, enabling companies to complete wells more efficiently and reduce overall operational costs. The decrease in penetrating time not as it were spares on operational costs but moreover empowers quicker get to to oil saves, possibly expanding generally venture profitability.

Extended Bit Life

The strong nature of polycrystalline jewel cutters implies that PDC bits regularly have a longer life expectancy than conventional roller cone bits. This amplified bit life diminishes the recurrence of bit substitutions, minimizing exorbitant downtime related with stumbling in and out of the wellbore. In numerous cases, a single PDC bit can penetrate an whole well segment, though different roller cone bits might be required for the same interval.

Reduced Non-Productive Time (NPT)

PDC bits contribute to a decrease in non-productive time by minimizing the require for bit changes and decreasing the probability of untimely bit disappointment. This expanded unwavering quality leads to less interferences in boring operations, permitting for more ceaseless and proficient well construction.

Improved Drilling Efficiency

The shearing activity of PDC bits requires less vitality to evacuate shake compared to the pulverizing instrument of roller cone bits. This made strides boring productivity interprets to lower vitality utilization and diminished wear on boring hardware, encourage contributing to taken a toll investment funds over the life of a boring project.

Maximizing Drilling Performance with PDC Bits

To completely saddle the potential of Polycrystalline Jewel Penetrate Bits and maximize penetrating execution, administrators must consider a few key variables and actualize best hones. By optimizing bit choice, penetrating parameters, and operational methods, companies can accomplish predominant comes about in their oil penetrating projects.

Customized Bit Design

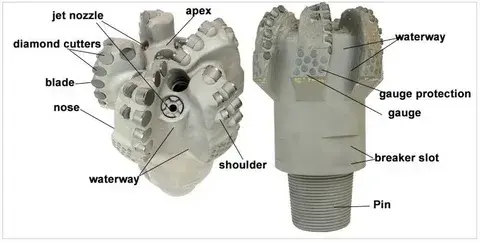

One of the most basic viewpoints of maximizing Polycrystalline Diamond Drill Bits (PDC bits) execution is selecting the right bit for the particular boring application. Components such as arrangement characteristics, well direction, and penetrating destinations ought to direct the bit choice handle. Custom-designed PDC bits, custom-made to the special necessities of a specific well or field, can essentially upgrade boring effectiveness and in general performance.

Optimized Drilling Parameters

Proper management of drilling parameters is essential for achieving optimal PDC bit performance. Key variables to consider include:

- Weight on Bit (WOB): Applying the appropriate amount of weight ensures efficient cutting action without overloading the bit.

- Rotary Speed: Maintaining the optimal rotations per minute (RPM) helps balance ROP with bit durability.

- Hydraulics: Proper management of drilling fluid flow rate and nozzle configuration ensures effective cuttings removal and bit cooling.

Advanced Drilling Techniques

Implementing advanced drilling techniques can further enhance the performance of PDC bits. Some effective strategies include:

- Managed Pressure Drilling (MPD): This technique helps maintain optimal bottomhole pressure, improving drilling efficiency and reducing the risk of formation damage.

- Vibration Mitigation: Employing tools and techniques to minimize harmful vibrations can extend bit life and improve overall drilling performance.

- Directional Control: Utilizing advanced directional drilling systems in conjunction with PDC bits can enable precise wellbore placement and improved drilling efficiency in complex reservoir structures.

Continuous Monitoring and Optimization

Real-time observing of penetrating parameters and bit execution is vital for maximizing PDC bit effectiveness. By analyzing information such as mechanical particular vitality (MSE), torque, and vibration levels, administrators can make educated choices to optimize penetrating parameters on the fly. This ceaseless optimization handle makes a difference guarantee that the PDC bit works at top execution all through the penetrating operation.

Conclusion

The apportionment of Polycrystalline Diamond Drill Bits in oil boring operations has revolutionized the industry, promoting unparalleled benefits in terms of boring efficiency, cost-effectiveness, and overall performance. By leveraging the advanced technology behind Polycrystalline Diamond Drill Bits, optimizing their application, and implementing best practices, oil and gas companies can significantly improve their boring capabilities and achieve superior results in their projects.

For companies looking to hoist their penetrating operations, collaborating with a trusted PDC bit producer is basic. Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the inquire about, advancement, and generation of high-quality PDC bore bits custom fitted to meet the assorted needs of the oil and gas industry. With our state-of-the-art 3,500m² office, progressed fabricating gear, and devoted R&D group, we are committed to conveying imaginative boring arrangements that drive your success.

Whether you're a medium to expansive oil benefit company looking for top-tier execution, a coal mining operation looking for cost-effective arrangements, or a water well penetrating group in require of solid apparatuses, our broad run of PDC bits and customization capabilities can meet your particular necessities. Do not let problematic boring instruments hold you back - take the to begin with step towards maximizing your boring productivity today.

To learn more around our PDC bit offerings and how they can change your penetrating operations, contact our master group at hainaisen@hnsdrillbit.com. Let's work together to open the full potential of your boring ventures with cutting-edge Polycrystalline Jewel Penetrate Bit innovation.

References

1. Smith, J. et al. (2021). "Advancements in Polycrystalline Diamond Compact Bit Technology for Enhanced Oil Drilling Performance." Journal of Petroleum Technology, 73(5), 62-70.

2. Johnson, R. and Brown, T. (2020). "Comparative Analysis of PDC vs. Roller Cone Bits in Deep Water Drilling Applications." Offshore Technology Conference Proceedings, OTC-30584-MS.

3. Zhang, Y. et al. (2019). "Thermal Stability Improvements in PDC Cutter Technology for High-Temperature Drilling Environments." SPE Drilling & Completion, 34(3), 217-229.

4. Garcia, M. and Lee, S. (2022). "Economic Impact of PDC Bit Utilization in Unconventional Oil and Gas Plays." SPE Economics & Management, 14(2), 84-96.

5. Wilson, K. et al. (2020). "Optimization of Drilling Parameters for PDC Bit Performance in Various Formation Types." IADC/SPE Drilling Conference and Exhibition, SPE-199642-MS.

6. Thompson, L. and Harris, N. (2021). "Next-Generation PDC Bit Designs for Enhanced Directional Drilling Capabilities." SPE/IADC Drilling Conference and Exhibition, SPE-204085-MS.