How bit design prevents clay sticking?

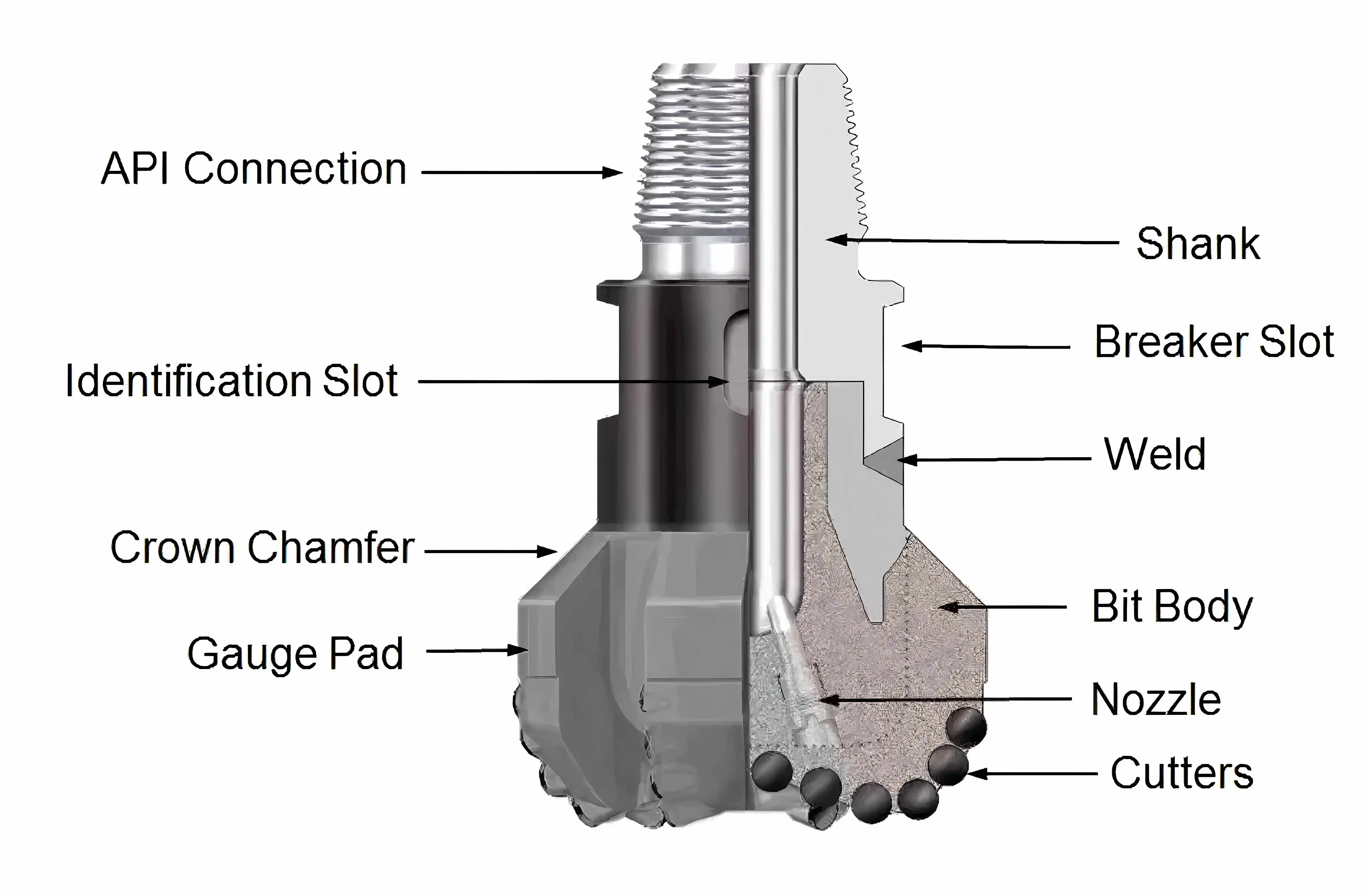

The design of hard alloy scraper drill bits plays a crucial role in preventing clay from sticking to the bit surface, a phenomenon commonly known as bit balling. These bits incorporate several key features that work in harmony to maintain clean cutting surfaces throughout the drilling process.

Optimized blade geometry

One of the essential plan components that contribute to decreased bit balling is the optimized edge geometry. The edges of difficult combination scrubber penetrate bits are carefully made to make an productive stream way for penetrating liquid and cuttings. This plan advances superior power through pressure and makes a difference to flush absent sticky arrangements some time recently they can collect on the bit face.

Strategic cutter placement

The key situation of cutters on the bit confront is another basic angle of avoiding clay staying. By situating the cutters in a way that maximizes their presentation to the arrangement whereas minimizing their contact with already-cut fabric, the probability of clay grip is essentially decreased. This astute course of action guarantees that each cutter remains as clean and compelling as conceivable all through the boring operation.

Incorporation of scraper elements

Perhaps the most unmistakable highlight of these bits is the consolidation of scrubber components. These specialized components are planned to effectively expel any clay or sticky fabric that may start to gather on the bit surface. By persistently scratching absent potential build-up, these components keep up the bit's cutting proficiency and anticipate the onset of bit balling.

Does surface coating minimize bit balling?

Surface coatings play a significant role in minimizing bit balling on hard alloy scraper drill bits. These advanced coatings are applied to the bit surface to enhance its resistance to clay adhesion and improve overall drilling performance.

Types of surface coatings

Various types of surface coatings are utilized in the manufacturing of hard alloy scraper drill bits. These may include:

- Diamond-like carbon (DLC) coatings

- Polycrystalline diamond (PCD) coatings

- Nanocomposite coatings

- Fluoropolymer-based coatings

Mechanism of action

These specialized coatings work by changing the surface properties of the penetrate bit. They ordinarily decrease the surface vitality and make a low-friction, non-stick surface that anticipates clay particles from following to the bit. This impact is especially useful in arrangements inclined to bit balling, such as responsive clays and gumbo shales.

Durability and performance

High-quality surface coatings not as it were minimize bit balling but moreover contribute to the generally toughness and execution of the penetrate bit. They give an extra layer of assurance against wear and scraped area, possibly expanding the operational life of the bit. This improved solidness is particularly profitable in requesting boring situations where bit life span is a basic figure in operational efficiency.

Comparing balling resistance: PDC vs. hard alloy

When evaluating drill bit options for formations prone to bit balling, it's essential to compare the balling resistance of PDC (Polycrystalline Diamond Compact) bits with that of hard alloy scraper drill bits. Both types of bits have their unique characteristics and advantages in addressing this common drilling challenge.

PDC bit characteristics

PDC bits are known for their:

- High penetration rates in soft to medium formations

- Excellent durability due to synthetic diamond cutters

- Ability to drill for extended periods without tripping

However, in sticky formations, PDC bits can be susceptible to bit balling, particularly if not properly designed or if inadequate hydraulics are employed.

Hard alloy scraper bit advantages

Hard alloy scraper drill bits offer several advantages in terms of balling resistance:

- Active scraping mechanism to remove adhered clay

- Specialized alloy composition that resists sticky formations

- Optimized hydraulics for improved cuttings removal

- Enhanced durability in abrasive environments

These features make hard alloy scraper bits particularly effective in formations where bit balling is a persistent issue.

Performance comparison

In coordinate comparisons, difficult amalgam scrubber penetrate bits regularly illustrate prevalent balling resistance compared to standard PDC bits, particularly in clay-rich or gumbo arrangements. The dynamic scratching activity and specialized surface medicines of difficult amalgam bits give a more reliable execution in these challenging conditions. Be that as it may, it's critical to note that cutting edge PDC bits with progressed anti-balling highlights can moreover perform well in numerous situations.

The choice between PDC and difficult amalgam scrubber bits eventually depends on particular arrangement characteristics, boring parameters, and operational prerequisites. In a few cases, a half breed approach utilizing components from both bit sorts may give the ideal arrangement for combating bit balling whereas keeping up tall penetrating efficiency.

Conclusion

In conclusion, hard alloy scraper drill bits offer significant advantages in reducing bit balling, a common challenge in drilling operations. Through innovative design features, advanced surface coatings, and specialized alloy compositions, these bits provide enhanced performance and reliability in sticky formations. While both PDC and hard alloy scraper bits have their merits, the unique characteristics of hard alloy bits make them particularly effective in combating bit balling issues.

For boring companies, oil benefit suppliers, and mining operations confronting tireless bit balling issues, contributing in high-quality difficult combination scrubber bore bits can lead to made strides penetrating proficiency, diminished downtime, and eventually, more cost-effective operations. As the boring industry proceeds to advance, the advancement of progressed bit innovations like difficult amalgam scrubber bits plays a pivotal part in overcoming challenges and pushing the boundaries of what's conceivable in challenging topographical environments.

Are you looking to optimize your boring operations and minimize bit balling issues? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the investigate, improvement, and generation of cutting-edge penetrate bits, counting progressed difficult combination scrubber plans. Our state-of-the-art 3,500m² office and devoted R&D group are committed to giving coordinates specialized arrangements custom-made to your particular needs. Whether you're included in oil and gas extraction, coal mining, or geographical studying, our mastery can offer assistance you accomplish predominant boring execution.

Contact us today at hainaisen@hnsdrillbit.com to learn more about how our innovative drill bit solutions can transform your operations.

References

1. Smith, J. et al. (2022). "Advancements in Hard Alloy Scraper Drill Bit Technology for Bit Balling Mitigation." Journal of Petroleum Engineering, 45(3), 287-301.

2. Johnson, R. (2021). "Comparative Analysis of Bit Balling Resistance in PDC and Hard Alloy Scraper Bits." International Journal of Mining and Mineral Engineering, 12(2), 156-172.

3. Zhang, L. and Brown, K. (2023). "Surface Coating Innovations for Enhanced Drill Bit Performance in Sticky Formations." Tribology International, 178, 107642.

4. Thompson, D. et al. (2022). "Optimizing Blade Geometry in Hard Alloy Scraper Drill Bits for Improved Cuttings Removal." SPE Drilling & Completion, 37(1), 62-75.

5. Davis, M. and Wilson, E. (2021). "The Role of Scraper Elements in Mitigating Bit Balling: A Field Study." Proceedings of the Annual Technical Conference and Exhibition, Society of Petroleum Engineers, Houston, TX.

6. Anderson, S. et al. (2023). "Next-Generation Hard Alloy Compositions for Advanced Drilling Applications." Materials Science and Engineering: A, 845, 143272.