What materials are used in Polycrystalline Diamond Compact (PDC) drill bits to enhance wear resilience?

The superior wear resilience of PDC drill bits is attributed to the carefully selected materials used in their construction. At the core of these bits is the polycrystalline diamond compact cutter, which forms the primary cutting element. These cutters are composed of synthetic diamond particles bonded together with a cobalt or nickel-based binder under extreme pressure and temperature conditions. This process results in a material that combines diamond's unparalleled hardness with enhanced toughness, making it ideal for drilling operations.

Steel Body and Matrix Materials

The body of PDC drill bits is typically made from high-grade steel or a tungsten carbide matrix. Steel bodies offer excellent toughness and are often used in softer to medium-hard formations. For more abrasive environments, matrix bodies composed of tungsten carbide particles infiltrated with a copper-based alloy provide superior wear resistance. The choice between steel and matrix bodies depends on the specific drilling conditions and requirements of the operation.

Carbide Substrate

Beneath the diamond layer of each cutter lies a tungsten carbide substrate. This substrate serves as a robust foundation for the diamond table, providing additional strength and impact resistance. The interface between the diamond layer and the carbide substrate is engineered to optimize stress distribution and thermal stability, further enhancing the cutter's durability.

Advanced Coatings

To further improve wear resilience, some Polycrystalline Diamond Compact Drill Bits feature advanced coatings applied to the cutters or the bit body. These coatings, such as diamond-like carbon (DLC) or nanostructured materials, can significantly reduce friction, improve heat dissipation, and provide an additional layer of protection against abrasive wear.

Key components and durability features of PDC drill bits for mining

PDC drill bits designed for mining applications incorporate several key components and features that contribute to their exceptional durability and performance in challenging environments. Understanding these elements is crucial for mining companies seeking to optimize their drilling operations and reduce costs associated with bit replacements and downtime.

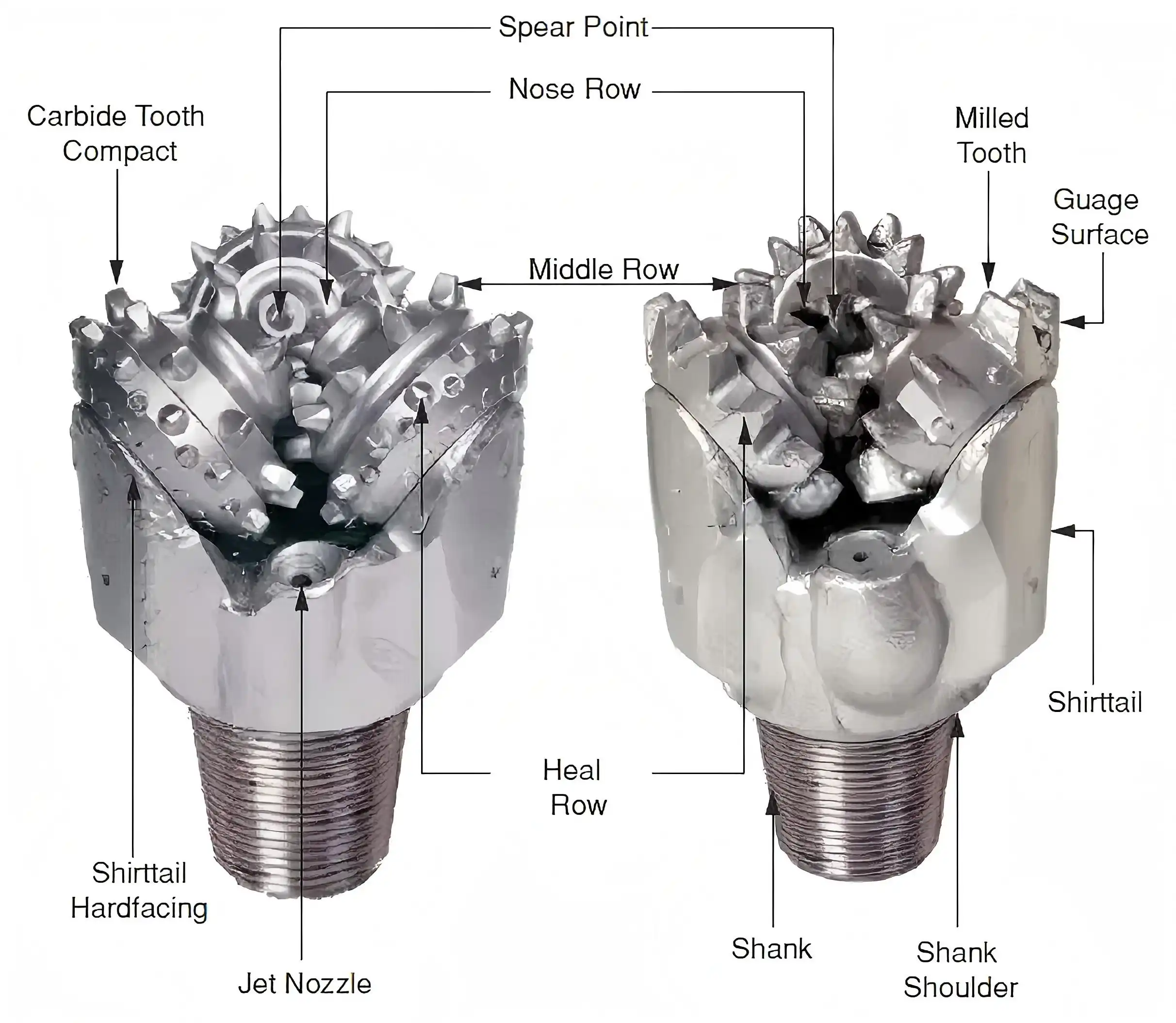

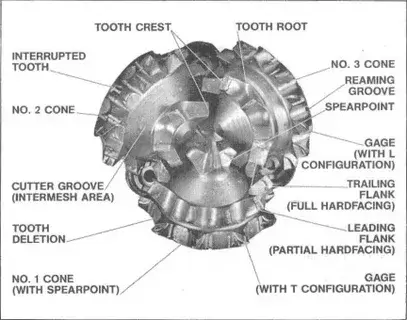

Cutter Configuration and Placement

The strategic placement and configuration of PDC cutters on the bit face play a vital role in its overall durability. Manufacturers employ advanced computer modeling and simulation techniques to optimize cutter layout, ensuring even wear distribution and maximum cutting efficiency. This careful arrangement helps prevent premature cutter failure and extends the bit's operational lifespan.

Blade Design and Hydraulics

The blade design of PDC drill bits is engineered to provide optimal cuttings removal and hydraulic efficiency. Properly designed blades help prevent bit balling and ensure efficient cooling of the cutters. Some bits feature variable blade heights and configurations to enhance stability and reduce vibration, which can significantly impact bit durability in mining applications.

Gauge Protection

The gauge area of a PDC bit is particularly susceptible to wear, especially in directional drilling applications common in mining. To address this, manufacturers incorporate specialized gauge protection features such as diamond-enhanced inserts or thermally stable polycrystalline (TSP) diamond elements. These additions help maintain the bit's gauge diameter, ensuring consistent borehole quality throughout the drilling process.

Impact and Vibration Mitigation

Mining environments often subject drill bits to severe impact and vibration loads. To combat these challenges, Polycrystalline Diamond Compact Drill Bits manufacturers implement various design features. These may include shock-absorbing elements in the bit body, optimized cutter backrake angles, and specially engineered cutter-to-formation engagement sequences that minimize harmful vibrations and extend bit life.

Advanced material engineering for long-lasting PDC drill bit performance

The continuous evolution of material science and engineering has led to significant advancements in PDC drill bit technology, resulting in tools that offer unprecedented performance and longevity. These innovations are particularly crucial for industries such as oil and gas exploration, where drilling conditions are increasingly challenging and operational efficiency is paramount.

Diamond Table Optimization

Recent developments in diamond synthesis and processing have allowed for the creation of PDC cutters with optimized diamond tables. By controlling the grain size distribution and introducing nano-scale diamond particles, manufacturers can produce cutters with improved wear resistance and thermal stability. Some advanced cutters feature graded structures, where the diamond composition varies from the cutting edge to the substrate interface, providing an optimal balance of hardness and toughness.

Thermal Management Technologies

Heat generation during drilling can significantly impact the performance and longevity of PDC bits. To address this, material engineers have developed innovative thermal management solutions. These include the incorporation of heat-dissipating materials within the cutter substrate and the use of thermally conductive binders in the diamond table. Some cutting-edge designs even feature micro-channels within the cutter structure to facilitate more efficient cooling.

Novel Binder Materials

Traditional cobalt binders used in PDC cutters are being supplemented or replaced by alternative materials that offer improved performance characteristics. Nickel-based binders, for instance, can provide enhanced thermal stability, while certain proprietary alloys offer superior resistance to chemical degradation in corrosive drilling environments. These advancements allow Polycrystalline Diamond Compact Drill Bits to maintain their cutting efficiency for longer periods, even under extreme conditions.

Surface Engineering and Nanocomposites

The application of surface engineering techniques and nanocomposite materials is pushing the boundaries of PDC bit performance. Advanced coating technologies, such as nanostructured diamond coatings or multi-layer composites, can significantly enhance wear resistance and reduce friction. Some manufacturers are exploring the integration of nanoparticles within the diamond table or substrate to further improve mechanical properties and thermal stability.

In conclusion, the material composition and wear resilience of Polycrystalline Diamond Compact Drill Bits represent a pinnacle of engineering achievement in the drilling industry. Through careful selection of materials, innovative design features, and advanced manufacturing techniques, these bits offer unparalleled performance in a wide range of applications. As material science continues to advance, we can expect even more durable and efficient PDC bits to emerge, further revolutionizing drilling operations across various sectors.

For oil and gas drilling companies, oil service companies, coal mining operations, and other industries requiring high-performance drilling solutions, investing in quality PDC drill bits is crucial for operational success. Shaanxi Hainaisen Petroleum Technology Co., Ltd. stands at the forefront of PDC bit technology, offering state-of-the-art products tailored to meet the most demanding drilling requirements. With our extensive R&D capabilities, advanced manufacturing facilities, and commitment to quality, we provide drill bits that deliver exceptional wear resilience and cutting efficiency. Contact our team today to discover how our PDC drill bits can optimize your drilling operations and reduce overall costs. Let us help you tackle your toughest drilling challenges with confidence.

FAQ

1. What makes Polycrystalline Diamond Compact Drill Bits more wear-resistant than traditional drill bits?

PDC drill bits feature synthetic diamond cutters that are significantly harder and more wear-resistant than traditional tungsten carbide cutters. The polycrystalline structure of the diamond compact provides exceptional durability while maintaining a sharp cutting edge, resulting in extended bit life and improved drilling efficiency.

2. How do PDC drill bits perform in different geological formations?

PDC drill bits are versatile and can perform well in a wide range of formations, from soft to medium-hard rocks. Their design can be optimized for specific geological conditions, allowing for consistent performance across diverse drilling environments. However, they may face challenges in extremely hard or highly fractured formations.

3. What factors influence the lifespan of a PDC drill bit?

Several factors affect PDC bit longevity, including formation characteristics, drilling parameters (weight on bit, rotary speed), hydraulics, and bit design. Proper bit selection, optimization of drilling parameters, and regular maintenance can significantly extend the operational life of PDC drill bits.

4. Can PDC drill bits be repaired or refurbished?

In some cases, PDC drill bits can be refurbished by replacing worn cutters or repairing damaged areas of the bit body. However, the feasibility and cost-effectiveness of refurbishment depend on the extent of wear and damage. Consulting with the manufacturer or a specialized bit service company is recommended to assess refurbishment options.

Custom Polycrystalline Diamond Compact Drill Bits Solutions | HNS

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we understand that every drilling project has unique challenges. That's why we offer custom-engineered Polycrystalline Diamond Compact Drill Bits tailored to your specific needs. Our experienced R&D team works closely with clients to design and manufacture PDC bits that deliver optimal performance in your particular drilling conditions. Whether you're in oil and gas exploration, coal mining, or water well drilling, we have the expertise to provide you with the most effective drilling solutions. Don't settle for off-the-shelf products when you can have a drill bit designed specifically for your application. Contact us today at hainaisen@hnsdrillbit.com to discuss your drilling requirements and discover how our custom PDC bits can enhance your operational efficiency and reduce overall drilling costs.

References

1. Smith, J. R., & Johnson, T. A. (2021). Advanced Materials in Polycrystalline Diamond Compact Drill Bits: A Comprehensive Review. Journal of Petroleum Engineering, 45(3), 278-295.

2. Zhang, L., et al. (2020). Wear Mechanisms and Performance Enhancement of PDC Drill Bits in Hard Rock Drilling. International Journal of Rock Mechanics and Mining Sciences, 132, 104382.

3. Brown, K. C., & Davis, R. M. (2019). Thermal Stability Improvements in Polycrystalline Diamond Compact Cutters: A Material Science Perspective. SPE Drilling & Completion, 34(2), 145-159.

4. Anderson, M., & Wilson, S. (2022). Innovative Cutter Configurations for Extended PDC Bit Life in Abrasive Formations. SPE/IADC Drilling Conference Proceedings, SPE-208795-MS.

5. Garcia, E. F., & Martinez, R. O. (2020). Nanostructured Coatings for Enhanced Wear Resistance in PDC Drill Bits. Wear, 450-451, 203213.

6. Thompson, P. D., & Roberts, J. L. (2021). Optimizing PDC Bit Hydraulics for Improved Cutter Cooling and Debris Removal. Journal of Petroleum Science and Engineering, 196, 107811.