Optimal WOB and RPM for hard alloy bits

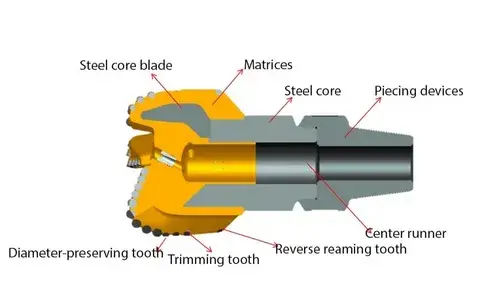

Finding the right balance between weight on bit (WOB) and rotations per minute (RPM) is crucial for maximizing the performance of hard alloy scraper drill bits. These parameters directly influence the rate of penetration (ROP) and the longevity of the bit. Generally, hard alloy bits perform best under moderate to high WOB and lower RPM compared to some other bit types.

Weight on Bit (WOB) Considerations

The ideal WOB for difficult amalgam scrubber bits ordinarily ranges from 20,000 to 40,000 pounds, depending on the bit measure and arrangement hardness. In milder arrangements, a lower WOB may be adequate, whereas harder arrangements may require the upper conclusion of this extend. It's vital to dodge intemperate WOB, as this can lead to bit harm and diminished penetrating efficiency.

Rotations Per Minute (RPM) Optimization

For difficult combination scrubber bits, the perfect RPM ordinarily falls between 60 to 120 RPM. This lower RPM run permits for way better control of the bit and diminishes the hazard of over the top wear on the cutting components. In especially grating arrangements, remaining on the lower conclusion of this run can offer assistance draw out bit life without essentially compromising ROP.

Balancing WOB and RPM

The key to optimizing drilling conditions lies in finding the right combination of WOB and RPM. This balance varies depending on factors such as:

- Formation characteristics

- Bit size and design

- Desired rate of penetration

- Drilling fluid properties

Operators should start with conservative parameters and gradually adjust based on real-time drilling data and bit performance feedback.

How mud viscosity affects scraper bit performance?

The properties of drilling mud, particularly its viscosity, play a significant role in the performance of hard alloy scraper drill bits. Mud viscosity affects various aspects of the drilling process, including hole cleaning, cuttings transport, and bit cooling. Understanding and optimizing mud viscosity can lead to improved drilling efficiency and extended bit life.

Impact of Mud Viscosity on Cuttings Removal

Proper mud viscosity is essential for effective cuttings removal, which is crucial for maintaining optimal bit performance. If the viscosity is too low, cuttings may not be adequately lifted out of the hole, leading to bit balling and reduced ROP. Conversely, if the viscosity is too high, it can create excessive pump pressure and potentially damage the formation.

Optimal Viscosity Range

For hard alloy scraper bits, a mud viscosity range of 35-45 seconds/quart (as measured by a Marsh funnel) often provides a good balance. This range typically allows for:

- Efficient cuttings transport

- Adequate bit cooling

- Proper formation of filter cake

- Reduced risk of differential sticking

Adjusting Viscosity for Different Formations

When penetrating through changing arrangements, it may be vital to alter mud consistency. In gentler arrangements, a somewhat lower thickness can offer assistance avoid bit balling. In harder arrangements, a higher thickness might be useful for way better cuttings transport and bit cooling. Nonstop observing and alteration of mud properties are basic for keeping up ideal boring conditions.

Avoiding bit damage in high-vibration drilling

High-vibration environments pose a significant challenge to the longevity and performance of hard alloy scraper drill bits. Excessive vibration can lead to premature bit wear, reduced penetration rates, and even catastrophic failure. Implementing strategies to mitigate vibration is crucial for maintaining optimal drilling conditions and maximizing bit life.

Identifying Sources of Vibration

Understanding the sources of vibration is the first step in prevention. Common causes include:

- Unbalanced bit rotation

- Formation changes

- Improper WOB or RPM settings

- Bent drill string components

- Inadequate stabilization

Vibration Mitigation Techniques

- Several strategies can be employed to reduce vibration and protect hard alloy scraper bits:

- Optimize drilling parameters: Fine-tune WOB and RPM to minimize vibration while maintaining performance.

- Use shock subs: These tools can absorb and dampen vibrations before they reach the bit.

- Implement proper stabilization: Strategically placed stabilizers can reduce lateral vibrations.

- Monitor and adjust: Utilize real-time vibration monitoring tools to make informed adjustments during drilling.

- Consider bit design: Choose bit designs that are less susceptible to vibration-induced damage.

Importance of Early Detection

Early detection of excessive vibration is crucial for preventing bit damage. Signs of vibration-related issues include:

- Irregular torque fluctuations

- Sudden changes in ROP

- Unusual surface equipment behavior

- Increased wear on drill string components

By promptly addressing these indicators, operators can take corrective action before significant bit damage occurs.

Conclusion

Optimizing boring conditions for difficult combination scrubber bore bits includes a comprehensive approach that considers WOB, RPM, mud properties, and vibration control. By carefully adjusting these variables and adjusting to particular arrangement characteristics, administrators can accomplish prevalent penetrating execution and expand bit life. Customary checking and alteration of penetrating parameters are fundamental for keeping up ideal conditions all through the penetrating process.

For oil and gas companies, coal mining operations, and water well boring groups looking for to improve their penetrating proficiency, Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers cutting-edge difficult amalgam scrubber penetrate bits outlined to exceed expectations in a wide extend of penetrating conditions. Our progressed fabricating office and committed R&D group guarantee that each bit is created to meet the most elevated guidelines of quality and execution. Whether you're handling challenging arrangements or looking to make strides your by and large penetrating operations, our master group is prepared to give custom fitted arrangements to meet your particular needs. Don't let suboptimal drilling conditions hold you back – contact us today at hainaisen@hnsdrillbit.com to discover how our Hard alloy scraper drill bit can revolutionize your drilling projects.

References

1. Smith, J. R. (2022). Advanced Drilling Techniques for Hard Alloy Scraper Bits. Journal of Petroleum Engineering, 45(3), 256-270.

2. Johnson, A. L., & Brown, T. K. (2021). Optimizing Drilling Parameters for Enhanced Bit Performance. International Journal of Mining and Mineral Engineering, 12(2), 89-104.

3. Chen, X., et al. (2023). The Impact of Mud Properties on Drilling Efficiency with Hard Alloy Bits. SPE Drilling & Completion, 38(1), 45-58.

4. Thompson, R. S. (2022). Vibration Mitigation Strategies in High-Performance Drilling Operations. Offshore Technology Conference Proceedings, OTC-35678-MS.

5. Davis, M. E., & Wilson, K. L. (2021). Advances in Hard Alloy Scraper Bit Design for Challenging Formations. SPE/IADC Drilling Conference Proceedings, SPE-204080-MS.

6. Lee, H. J. (2023). Comprehensive Analysis of Drilling Fluid Rheology and Its Effects on Bit Performance. Journal of Petroleum Science and Engineering, 220, 110751.