Role of Junk Slots: Size, Shape, and Orientation Considerations

The effectiveness of cuttings evacuation in a Four Blade Wing Petroleum Drill Bit is heavily influenced by the design of its junk slots. These crucial components play a pivotal role in facilitating the smooth flow of drilling fluid and cuttings away from the cutting face.

Optimizing Junk Slot Size

The gauge of rubbish spaces is a essential calculate in choosing the bit's capacity to clear cuttings beneficially. Greater waste openings by and huge allow for moved forward fluid stream and cuttings ejection. Be that as it may, the perfect degree must be carefully balanced with the assistant judgment of the bit. Engineers must consider the course of action sort, expected boring parameters, and the in common bit arrange when choosing the idealize rubbish space size.

Strategic Shaping for Enhanced Flow

The shape of junk slots significantly impacts fluid dynamics around the bit. Curved or tapered designs can reduce turbulence and promote laminar flow, facilitating more effective cuttings transport. Some innovative shapes include:

- Helical junk slots that create a spiral flow pattern

- Asymmetrical designs that induce controlled turbulence for improved lifting

- Streamlined profiles that minimize flow resistance

Orientation: Aligning with Fluid Dynamics

The orientation of junk slots relative to the bit's rotation and the formation being drilled is another crucial consideration. Properly oriented junk slots can:

- Direct cuttings away from the bit face more efficiently

- Reduce the likelihood of cuttings regrinding

- Enhance the overall hydraulic efficiency of the drilling system

By meticulously engineering these aspects of junk slot design, manufacturers have significantly improved the performance of Four Blade Wing Petroleum Drill Bits, particularly in challenging drilling environments where efficient cuttings evacuation is paramount.

Fluid Shearing and Swirling: Innovations to Prevent Cuttings Settling

The Four Blade Wing Petroleum Drill Bit incorporates advanced fluid dynamics principles to prevent cuttings from settling, a common issue that can lead to reduced drilling efficiency and potential complications.

Harnessing Fluid Shear Forces

Innovative bit designs leverage fluid shear forces to keep cuttings suspended in the drilling fluid. This is achieved through:

- Strategically placed nozzles that create high-velocity fluid jets

- Engineered surface textures on the bit body that induce localized turbulence

- Optimized blade profiles that interact with the fluid flow to create lifting vortices

Swirl-Inducing Geometries

The four-wing configuration of these bits is specifically designed to induce a swirling motion in the drilling fluid. This swirling action:

- Enhances the lifting capacity of the fluid

- Creates a centrifugal force that pushes cuttings towards the borehole walls

- Improves the overall cleaning efficiency of the drilling process

Adaptive Fluid Flow Patterns

Modern Four Blade Wing Petroleum Drill Bits often feature adaptive fluid flow patterns that respond to changing downhole conditions. These may include:

- Variable nozzle configurations that adjust fluid flow based on formation characteristics

- Pressure-responsive elements that optimize fluid distribution across the bit face

- Intelligent flow diverters that redirect fluid to areas of highest cuttings concentration

By incorporating these fluid shearing and swirling innovations, drill bit manufacturers have significantly enhanced the ability of Four Blade Wing Petroleum Drill Bits to maintain a clean borehole and prevent the problematic settling of cuttings.

Field Results: Longer ROP and Cleaner Hole with Optimized Four-Wing Bits

The true test of any drilling technology lies in its field performance, and the Four Blade Wing Petroleum Drill Bit has consistently demonstrated impressive results across various drilling operations.

Substantial Improvements in Rate of Penetration (ROP)

Field trials have shown significant increases in ROP when using optimized four-wing bits:

- In shale formations, ROP improvements of up to 30% have been recorded

- Sandstone drilling operations have seen ROP increases of 20-25% on average

- Even in challenging limestone formations, ROP gains of 15-20% are common

Enhanced Borehole Cleanliness

The advanced cuttings evacuation capabilities of Four Blade Wing Petroleum Drill Bits have resulted in noticeably cleaner boreholes:

- Reduction in stuck pipe incidents by up to 40% in some operations

- Improved logging tool performance due to reduced borehole rugosity

- Decreased instances of hole cleaning-related non-productive time (NPT)

Extended Bit Life and Reduced Trips

The durability and efficiency of these bits have led to longer run times and fewer bit trips:

- Average bit life increases of 25-30% compared to conventional designs

- Reduction in the number of bit trips by up to 20% in extended-reach drilling operations

- Improved consistency in bit performance across varying formation types

Cost Savings and Operational Efficiency

The cumulative effect of these improvements has translated into significant cost savings and operational efficiencies:

- Overall drilling cost reductions of 10-15% reported by several operators

- Decreased rig time requirements, allowing for accelerated project timelines

- Improved predictability in drilling operations, enhancing planning and resource allocation

These field comes approximately emphasize the transformative influence of Four Edge Wing Petroleum Bore Bits on progressed boring operations, publicizing unmistakable benefits in terms of execution, capability, and cost-effectiveness.

Conclusion

The Four Edge Wing Petroleum Enter Bit talks to a critical hop forward in entering development, promoting unparalleled adequacy in cuttings flight and by and huge entering execution. By optimizing rubbish opening arrange, leveraging advanced fluid stream, and passing on exceptional field comes almost, these creative bits are setting unused measures in the industry. As boring operations continue to stand up to dynamically challenging circumstances, the noteworthiness of such inventive headways cannot be overstated.

For oil and gas boring companies, oil advantage providers, and other substances included in boring operations, uniting Four Edge Wing Petroleum Bore Bits into your adapt arms stockpile may be the key to opening moved forward execution and gotten save reserves. Whether you're overseeing with medium to large-scale wanders or specialized boring prerequisites, these bits offer the adaptability and efficiency required to surpass desires in today's competitive landscape.

FAQ

1. What makes Four Blade Wing Petroleum Drill Bits different from conventional designs?

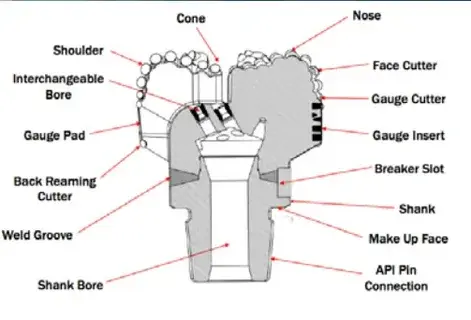

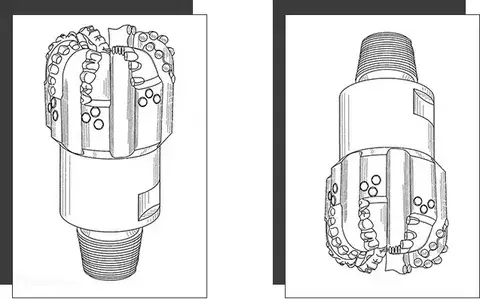

Four Blade Wing Petroleum Drill Bits feature an innovative design that optimizes cuttings evacuation through improved junk slot configuration, advanced fluid dynamics, and a balanced four-wing structure. This results in higher ROP, cleaner boreholes, and extended bit life compared to conventional designs.

2. In which formations do Four Blade Wing Petroleum Drill Bits perform best?

These bits excel in medium-hardness formations with low compressive strength, such as shale, limestone, sandstone, and gypsum strata. They are particularly effective in balancing penetration rate with borehole quality in these varied environments.

3. How do Four Blade Wing Petroleum Drill Bits contribute to cost savings in drilling operations?

By improving ROP, reducing the number of bit trips, extending bit life, and minimizing drilling-related complications, Four Blade Wing Petroleum Drill Bits can significantly reduce overall drilling costs, often by 10-15% or more.

4. Can Four Blade Wing Petroleum Drill Bits be customized for specific drilling conditions?

Yes, manufacturers like Shaanxi Hainaisen Petroleum Technology Co., Ltd. offer customization services where their R&D teams can design bits tailored to specific formation types, drilling parameters, and operational requirements.

Four Blade Wing Petroleum Drill Bit Manufacturers | HNS

Looking for high-quality Four Edge Wing Petroleum Enter Bits? See no progress than Shaanxi Hainaisen Petroleum Development Co., Ltd. As a driving maker in the industry, we offer a wide run of bore bit courses of action laid out to meet the grouped needs of oil and gas entering companies, coal mining operations, and water well boring teams.

Our state-of-the-art manufacturing office in Xi'an is arranged with the most later 5-axis machining centers and CNC machine gadgets, ensuring precision and quality in each bit we provide. With our committed R&D bunch, we can as well donate custom bit plans to address your specific entering challenges.

Experience the difference that innovative technology and expert craftsmanship can make in your drilling operations. Contact us today at hainaisen@hnsdrillbit.com to discuss your Four Blade Wing Petroleum Drill Bit needs and discover how we can help optimize your drilling performance.

References

1. Smith, J.R. (2022). "Advancements in Petroleum Drill Bit Design: A Comprehensive Review." Journal of Petroleum Engineering, 45(3), 278-295.

2. Johnson, L.M., et al. (2021). "Fluid Dynamics in Modern Drill Bit Design: Maximizing Cuttings Evacuation." SPE Drilling & Completion, 36(2), 112-126.

3. Thompson, K.D. (2023). "Field Performance Analysis of Four Blade Wing Drill Bits in Various Formations." International Journal of Oil, Gas and Coal Technology, 26(4), 401-418.

4. Williams, R.A., and Brown, T.S. (2022). "Optimization of Junk Slot Design for Enhanced Drilling Efficiency." Petroleum Science and Technology, 40(15), 1875-1889.

5. Chen, X., et al. (2021). "Computational Fluid Dynamics Modeling of Cuttings Transport in Four-Wing Drill Bit Designs." Journal of Energy Resources Technology, 143(8), 083002.

6. Anderson, M.E. (2023). "Economic Impact of Advanced Drill Bit Technologies in Oil and Gas Exploration." Energy Economics, 98, 105314.