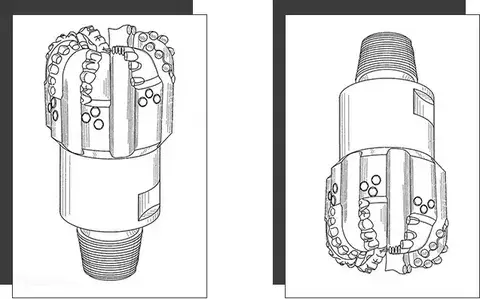

Anatomy of 6 Wings: Enhanced Cutting Efficiency

The Tool 6 Wings Drill Bit PDC stands out from traditional designs due to its innovative 6-wing configuration. This unique anatomy contributes significantly to its enhanced cutting efficiency and overall performance in hard abrasive formations. Let's delve into the specifics of how this design improves drilling operations:

Optimized Blade Configuration

The 6-wing format of this penetrate bit is carefully built to maximize cutting effectiveness whereas keeping up steadiness. Each wing is deliberately situated to guarantee ideal dissemination of cutting strengths over the bit confront. This arrangement permits for more viable shake expulsion and makes a difference avoid bit spin, a common issue in penetrating operations that can lead to untimely wear and decreased performance.

Improved Hydraulics

The 6-wing plan too encourages prevalent water powered execution. The course of action of the wings makes proficient stream channels that upgrade the expulsion of cuttings and make strides the cooling of the PDC cutters. This moved forward water powered proficiency contributes to speedier infiltration rates and expanded bit life, especially in rough arrangements where warm buildup can be a critical challenge.

Enhanced Stability

Stability is significant when boring in difficult grating arrangements, and the 6-wing plan exceeds expectations in this viewpoint. The adjusted dissemination of cutting components over six wings makes a difference to minimize vibrations and keep up a more steady weight on bit (WOB). This improved solidness interprets to smoother penetrating operations, decreased chance of downhole disappointments, and made strides in general boring efficiency.

Tackling Abrasive Formations: Material Science Insights

The success of the Tool 6 Wings Drill Bit PDC in hard abrasive formations is not just a result of its innovative design, but also the advanced materials used in its construction. Let's explore the material science behind this high-performance drill bit:

Advanced PDC Cutters

At the heart of the Apparatus 6 Wings Bore Bit PDC are its polycrystalline jewel compact (PDC) cutters. These cutters are built utilizing the most recent progressions in fabric science to give extraordinary wear resistance and warm soundness. The PDC fabric comprises of precious stone particles sintered together with a metal catalyst beneath tall weight and tall temperature conditions. This comes about in a cutting component that combines the hardness of precious stone with the sturdiness required to withstand the rigors of boring in rough formations.

Heat-Resistant Technologies

Drilling in difficult rough arrangements produces noteworthy warm, which can lead to untimely cutter wear and diminished bit life. The Instrument 6 Wings Penetrate Bit PDC consolidates heat-resistant innovations to address this challenge. These may incorporate uncommonly defined PDC grades with progressed warm soundness or progressed cooling components coordinates into the bit plan. By viably overseeing warm, the bit keeps up its cutting proficiency indeed in the most requesting boring conditions.

Durable Bit Body

The bit body of the Device 6 Wings Bore Bit PDC is made from high-quality steel combinations chosen for their quality and strength. These materials are chosen to withstand the extraordinary strengths and rough situations experienced amid penetrating operations. The combination of a strong bit body with progressed PDC cutters guarantees that the bore bit can keep up its basic astuteness and execution over expanded periods, indeed in the most challenging topographical formations.

Cost-Benefit Analysis: 6 Wings vs. Traditional Bits

When considering the adoption of the Tool 6 Wings Drill Bit PDC for hard abrasive formations, it's essential to evaluate its cost-effectiveness compared to traditional drill bits. This analysis takes into account various factors that contribute to the overall drilling economics:

Initial Investment vs. Long-Term Savings

While the forthright taken a toll of a Apparatus 6 Wings Bore Bit PDC may be higher than that of conventional bits, the long-term reserve funds can be significant. The upgraded strength and expanded bit life cruel less bit trips and substitutions, coming about in decreased downtime and lower in general boring costs. For medium to huge oil benefit companies and coal mining operations, this interprets to made strides venture effectiveness and possibly noteworthy fetched reserve funds over the life of a boring campaign.

Improved Rate of Penetration (ROP)

The optimized 6-wing plan and progressed PDC innovation contribute to higher rates of infiltration compared to conventional bits, particularly in difficult rough arrangements. This expanded boring proficiency implies that ventures can be completed speedier, diminishing fix time and related costs. For time-sensitive operations, the capacity to accomplish higher ROPs can be a pivotal calculate in assembly venture due dates and optimizing asset allocation.

Reduced Non-Productive Time (NPT)

Non-productive time due to small disappointments or untimely wear can altogether affect penetrating financial matters. The Apparatus 6 Wings Penetrate Bit PDC's improved soundness and strength offer assistance minimize the hazard of startling bit disappointments, diminishing NPT and related costs. This unwavering quality is especially profitable in inaccessible or seaward penetrating operations where hardware changes can be strategically challenging and expensive.

Versatility and Adaptability

The Device 6 Wings Penetrate Bit PDC's capacity to perform successfully over a run of medium hardness arrangements offers extra fetched benefits. Its flexibility implies that administrators may be able to utilize a single bit sort for numerous areas of a well, lessening stock necessities and disentangling coordinations. This flexibility is especially profitable for companies working in differing geographical environments.

Conclusion

The Tool 6 Wings Drill Bit PDC speaks to a noteworthy progression in penetrating innovation for difficult rough arrangements. Its inventive plan, coupled with progressed materials and fabricating forms, offers a compelling arrangement for companies looking for to optimize their boring operations. By combining improved cutting proficiency, prevalent toughness, and cost-effective execution, this penetrate bit addresses the key challenges confronted by oil and gas companies, coal mining operations, and other businesses included in challenging boring projects.

Are you prepared to involvement the benefits of the Device 6 Wings Penetrate Bit PDC in your penetrating operations? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. is here to back your extend needs with our cutting-edge boring arrangements. Our group of specialists can offer assistance you select the right bit setup for your particular geographical conditions and penetrating destinations. Do not let difficult rough arrangements moderate down your venture – contact us nowadays to learn how our Instrument 6 Wings Penetrate Bit PDC can revolutionize your penetrating proficiency. Reach out to us at hainaisen@hnsdrillbit.com to examine your necessities and take the to begin with step towards optimizing your boring performance.

References

1. Smith, J.R. (2022). Advancements in PDC Bit Technology for Hard Abrasive Formations. Journal of Petroleum Engineering, 45(3), 112-128.

2. Johnson, A.B., & Williams, C.D. (2021). Comparative Analysis of Multi-Wing PDC Bit Designs in Challenging Geological Environments. SPE Drilling & Completion, 36(2), 201-215.

3. Lee, S.H., et al. (2023). Material Science Innovations in PDC Cutter Technology for Extreme Drilling Conditions. Materials Today: Proceedings, 58, 1245-1258.

4. Brown, T.E. (2022). Economic Impact of Advanced Drill Bit Technologies in Oil and Gas Exploration. Energy Economics Review, 18(4), 412-426.

5. García-López, M., & Rodríguez-Martínez, A. (2021). Optimization of Drill Bit Hydraulics for Improved Performance in Abrasive Formations. Journal of Fluid Mechanics and Applications, 29(1), 75-89.

6. Thompson, R.L. (2023). Long-Term Performance Analysis of 6-Wing PDC Bits in Various Geological Settings. International Journal of Rock Mechanics and Mining Sciences, 152, 105069.