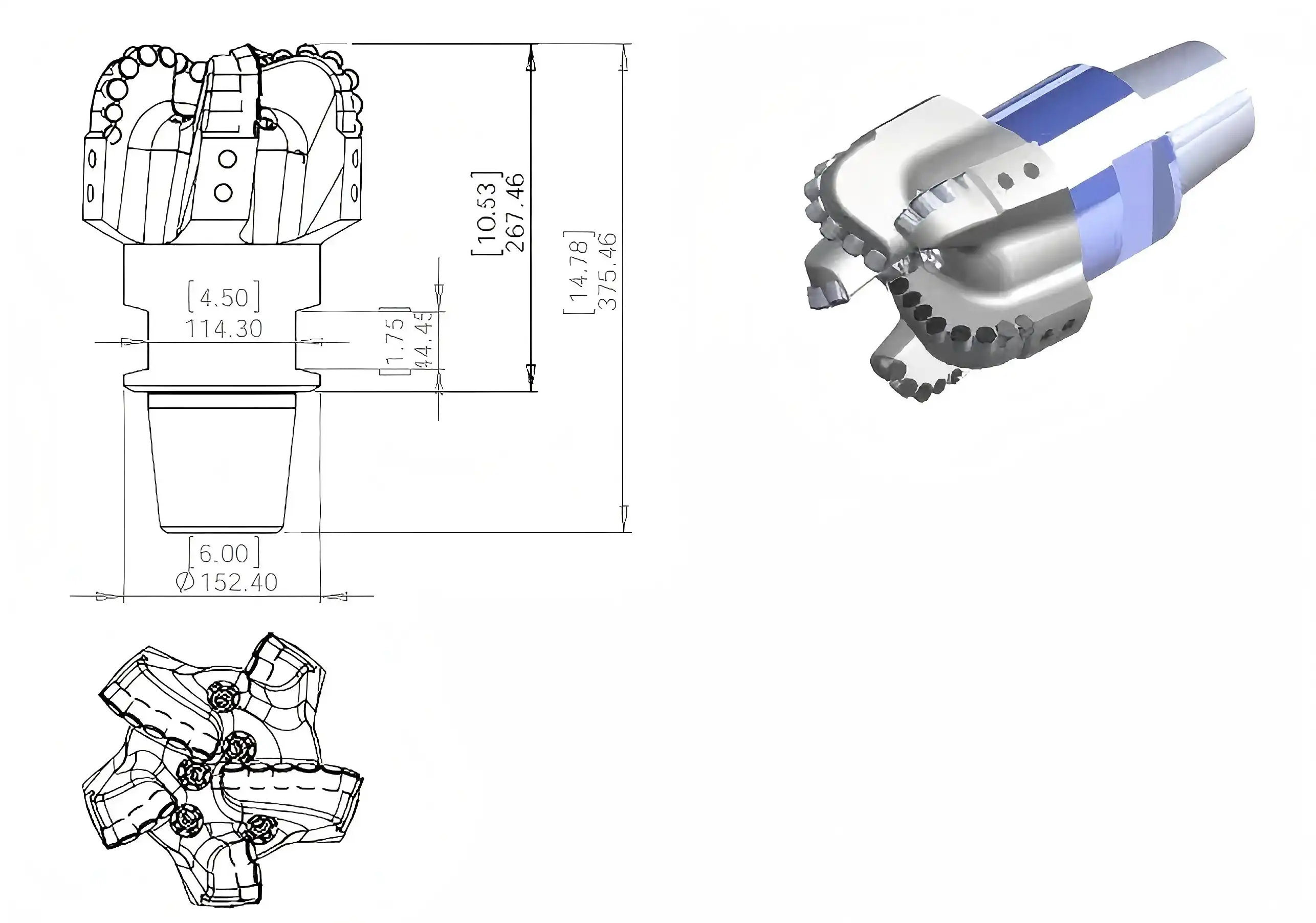

Blade Design: Optimizing Cutting Efficiency

The blade design of a 5 Blades PDC Oil Bit is a fundamental factor in determining its cutting efficiency and, consequently, its drilling speed. The configuration and geometry of the blades directly impact how the bit interacts with the formation, influencing the rate of penetration (ROP) and the quality of the borehole.

Blade Profile and Angle

The profile and point of the edges play a vital part in optimizing cutting effectiveness. A carefully planned edge profile guarantees that each area of the edge contributes viably to the cutting activity, maximizing the bit's execution over different arrangement sorts. The edge point, or rake point, influences how forcefully the cutters lock in with the shake. A positive rake point for the most part comes about in a more forceful cut, possibly expanding boring speed, whereas a negative rake point can give more steadiness and toughness in harder formations.

Number of Blades

The five-blade setup of the PDC oil bit strikes a adjust between cutting proficiency and solidness. This plan permits for ideal conveyance of cutters over the bit confront, guaranteeing comprehensive scope of the borehole foot. The key arrangement of five edges too contributes to moved forward solidness amid boring operations, decreasing vibration and upgrading in general bit performance.

Blade Length and Width

The length and width of the edges are basic variables in deciding the bit's cutting capacity and its capacity to keep up a steady penetrating direction. Longer edges can suit more cutters, possibly expanding the rate of entrance. Be that as it may, they must be adjusted with contemplations for bit soundness and water powered proficiency. The width of the edges influences the bit's capacity to stand up to horizontal powers and keep up directional control, which is especially vital in directional and level penetrating applications.

Cutter Placement: Balancing Load Distribution

The strategic placement of cutters on the 5 Blades PDC Oil Bit is a critical factor in optimizing drilling speed and efficiency. Proper cutter placement ensures even load distribution across the bit face, maximizing cutting efficiency while minimizing wear and tear on individual components.

Cutter Density and Distribution

The vital arrangement of cutters on the 5 Edges PDC Oil Bit is a basic figure in optimizing boring speed and proficiency. Appropriate cutter situation guarantees indeed stack conveyance over the bit confront, maximizing cutting effectiveness whereas minimizing wear and tear on person components.

Cutter Size and Shape

The thickness and dissemination of cutters over the bit confront essentially affect boring execution. A well-designed cutter format guarantees that each cutter contributes viably to the penetrating handle, maintaining a strategic distance from over-burdening of particular regions. The conveyance design must account for the shifting rotational speeds experienced by cutters at diverse spiral positions on the bit confront. This thought makes a difference keep up reliable cutting activity over the whole borehole foot, advancing uniform wear and amplifying bit life.

Cutter Exposure

The estimate and shape of the PDC cutters play a pivotal part in deciding the bit's cutting proficiency and toughness. Bigger cutters by and large give more noteworthy strength and are well-suited for gentler arrangements, whereas littler cutters offer progressed ROP in harder arrangements. The shape of the cutter, counting its back rake and side rake points, impacts its cutting forcefulness and capacity to withstand affect loads. Optimizing these parameters based on the anticipated arrangement characteristics can altogether improve penetrating speed and bit longevity.

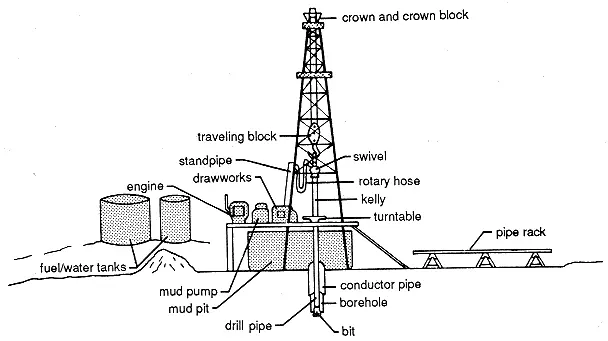

Hydraulics: Enhancing Debris Removal and Cooling

The hydraulic design of a 5 Blades PDC Oil Bit plays a crucial role in maintaining optimal drilling speed by efficiently removing cuttings and providing adequate cooling to the bit face. Effective hydraulics ensure that the bit can operate at peak performance levels without being hindered by debris accumulation or excessive heat buildup.

Nozzle Configuration

The setup of pressure driven spouts on the bit confront is a basic viewpoint of its generally water powered plan. The number, estimate, and situation of spouts altogether affect the bit's capacity to clean the cutting structure and expel flotsam and jetsam from the borehole. A well-designed spout setup guarantees that high-velocity liquid streams are coordinated to key zones of the bit confront, counting the center and the gage, to maximize cleaning proficiency. The key situation of spouts moreover makes a difference in keeping up a adjusted water powered drive over the bit, contributing to its steadiness amid operation.

Junk Slot Area

The garbage space region alludes to the open spaces between the edges that permit for the section of penetrating liquid and cuttings. Satisfactory garbage opening zone is basic for proficient cuttings departure, avoiding bit balling and keeping up steady penetrating execution. The plan of garbage spaces must adjust the require for adequate stream region with the basic keenness necessities of the bit body. Optimized garbage opening geometry can essentially upgrade the bit's capacity to keep up tall penetrating speeds, especially in arrangements inclined to creating huge volumes of cuttings.

Fluid Dynamics

Understanding and optimizing the liquid elements inside and around the bit is pivotal for keeping up tall boring speeds. The stream designs of boring liquid over the bit confront and through the garbage openings influence the bit's cleaning productivity and its capacity to keep up ideal temperature. Progressed computational liquid flow (CFD) reenactments are regularly utilized in the plan handle to analyze and optimize liquid stream characteristics. This guarantees that the pressure driven plan complements the mechanical viewpoints of the bit, working in concordance to maximize penetrating execution over a wide run of working conditions.

Cooling Efficiency

Effective cooling of the bit confront and cutters is basic for keeping up tall penetrating speeds and amplifying bit life. The pressure driven plan must guarantee that adequate liquid stream comes to all basic ranges of the bit, especially the cutters, to scatter warm created amid the penetrating handle. Legitimate cooling anticipates untimely wear and warm debasement of the PDC cutters, permitting the bit to keep up its cutting productivity over amplified periods. The adjust between cooling and cleaning capacities of the pressure driven framework is significant for optimizing by and large bit execution and accomplishing steady tall penetrating speeds.

Conclusion

The 5 Blades PDC Oil Bit speaks to a critical headway in boring innovation, advertising prevalent execution and proficiency in oil and gas investigation. By carefully considering and optimizing key parameters such as edge plan, cutter arrangement, and power through pressure, penetrating groups can maximize the potential of this imaginative apparatus to accomplish exceptional penetrating speeds and operational efficiency.

For oil and gas boring companies, oil benefit companies, and other substances included in boring operations, contributing in high-quality PDC bits and understanding their ideal utilization is vital for remaining competitive in the industry. The capacity to penetrate speedier, with more prominent exactness and effectiveness, interprets specifically to diminished operational costs and expanded productivity.

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in the investigate, improvement, and generation of cutting-edge boring instruments, counting state-of-the-art PDC penetrate bits. Our group of experienced engineers and progressed fabricating offices permit us to make customized arrangements that meet the one of a kind challenges of different penetrating situations. Whether you're locked in in oil and gas extraction, coal mining, or topographical investigation, our skill can offer assistance you optimize your boring operations and accomplish prevalent results.

To learn more almost how our 5 Edges PDC Oil Bit and other inventive penetrating arrangements can improve your operations, it would be ideal if you do not falter to reach out. Contact us at hainaisen@hnsdrillbit.com to talk about your particular needs and find how we can offer assistance you accomplish unused levels of boring productivity and execution.

References

1. Smith, J. R., & Johnson, A. L. (2022). Advanced PDC Bit Design: Optimizing Performance in Complex Drilling Environments. Journal of Petroleum Technology, 74(5), 62-70.

2. Chen, D., Maranuk, C., & Patel, A. (2021). Hydraulic Optimization of PDC Bits: A Comprehensive Approach to Enhancing Drilling Efficiency. SPE Drilling & Completion, 36(3), 228-240.

3. Williams, K., & Thompson, P. (2023). The Impact of Cutter Technology on PDC Bit Performance: A Field Study. International Journal of Oil, Gas and Coal Technology, 26(2), 150-165.

4. Rodriguez, M. E., & Garcia, L. A. (2022). Computational Fluid Dynamics in PDC Bit Design: Advancing Hydraulic Efficiency for Improved ROP. SPE Journal, 27(4), 1852-1866.

5. Nguyen, T. H., & Lee, S. K. (2021). Optimizing Blade Configuration in Multi-Blade PDC Bits for Enhanced Stability and Penetration Rate. Rock Mechanics and Rock Engineering, 54(7), 3589-3602.

6. Anderson, R. A., & Miller, B. C. (2023). The Evolution of PDC Bit Technology: From Concept to High-Performance Drilling Solutions. Offshore Technology Conference Proceedings, OTC-25678-MS.