Cutting Mechanism: Shearing vs. Crushing

The fundamental difference between PDC mining bits and tricone bits lies in their cutting mechanisms. This distinction greatly influences their performance and suitability for different drilling conditions.

PDC Mining Bit: Shearing Action

PDC (Polycrystalline Precious stone Compact) bits utilize a shearing activity to cut through shake arrangements. These bits highlight settled cutter edges implanted with diamond-impregnated embeds. As the bit pivots, these razor-sharp cutters shear absent the shake, making a ceaseless cutting activity. This strategy is especially viable in gentler to medium-hard arrangements, where it can accomplish higher infiltration rates and smoother boreholes.

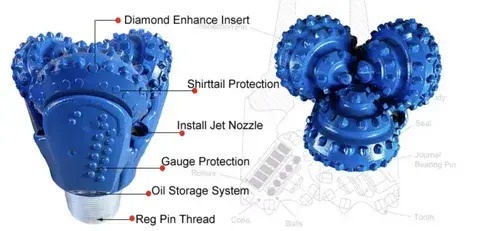

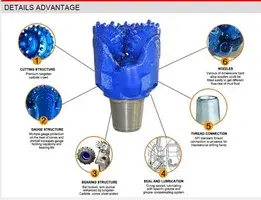

Tricone Bit: Crushing and Scraping

In differentiate, tricone bits utilize a combination of smashing and scratching activities to break down shake arrangements. These bits comprise of three cone-shaped segments that pivot freely as the bit turns. The cones are studded with tungsten carbide embeds or processed steel teeth that smash and gouge the shake as they roll. This plan is well-suited for harder shake arrangements where the smashing activity can be more viable than shearing.

Performance Comparison in Various Rock Formations

The viability of PDC mining bits and tricone bits can shift essentially depending on the sort of shake arrangement experienced amid penetrating operations. Understanding these execution contrasts is pivotal for selecting the ideal bit for particular topographical conditions.

Soft to Medium Formations

In softer to medium-hard formations, PDC mining bits generally outperform tricone bits. The shearing action of PDC cutters allows for faster penetration rates and more efficient removal of rock cuttings. This results in smoother boreholes and reduced drilling time. PDC bits also tend to maintain their cutting efficiency for longer periods in these formations, leading to fewer bit trips and increased overall productivity.

Hard and Abrasive Formations

Tricone bits have customarily been the go-to choice for difficult and grating shake arrangements. The pulverizing activity of the pivoting cones is successful at breaking down extreme shake structures. Be that as it may, progressions in PDC cutter innovation have extended the run of arrangements where PDC bits can be utilized viably. Cutting edge PDC mining bits with extraordinarily outlined cutters and optimized edge arrangements can presently handle progressively harder arrangements, challenging the dominance of tricone bits in this arena.

Interbedded Formations

In interbedded arrangements, where layers of delicate and difficult shake interchange, the choice between PDC and tricone bits gets to be more complex. PDC bits may battle with sudden changes in arrangement hardness, possibly driving to vibration and untimely wear. Tricone bits, with their capacity to adjust to changing hardness levels, can now and then give more reliable execution over interbedded segments. In any case, progressed PDC bit plans with stabilization highlights and optimized cutter situation are progressively able to handle these challenging conditions.

Cost-Benefit Analysis: When to Choose PDC?

When considering whether to invest in a PDC mining bit or a tricone bit, it's essential to conduct a thorough cost-benefit analysis. While PDC bits often have a higher initial cost, their potential for increased drilling efficiency and longer bit life can lead to significant savings in the long run.

Initial Investment vs. Long-Term Savings

PDC bits typically come with a higher upfront cost compared to tricone bits. However, this initial investment can be offset by several factors:

- Increased Rate of Penetration (ROP): PDC bits often achieve higher ROPs, especially in softer to medium-hard formations, leading to reduced drilling time and associated costs.

- Extended Bit Life: The durable nature of PDC cutters means these bits can often drill for longer periods before requiring replacement, reducing the frequency of bit trips and associated downtime.

- Improved Borehole Quality: The shearing action of PDC bits tends to produce smoother boreholes, which can lead to easier casing runs and potentially reduce overall well construction costs.

Operational Considerations

When evaluating the cost-effectiveness of PDC mining bits, it's important to consider operational factors such as:

- Formation Characteristics: In softer to medium-hard formations, PDC bits can provide significant cost savings through increased efficiency and reduced drilling time.

- Drilling Parameters: PDC bits often require different weight-on-bit (WOB) and rotary speed settings compared to tricone bits. Ensuring your drilling equipment can accommodate these parameters is crucial for optimal performance.

- Crew Training: While PDC bits are becoming increasingly common, some drilling crews may be more familiar with tricone bits. Additional training may be necessary to ensure proper handling and optimization of PDC bit performance.

Long-Term Value

For operations in reasonable arrangements, the long-term esteem recommendation of PDC mining bits can be compelling. The combination of expanded ROP, expanded bit life, and made strides borehole quality can lead to significant fetched reserve funds over the life of a boring venture. This is especially genuine for large-scale operations or ventures with different wells, where the aggregate benefits of PDC innovation can essentially affect the foot line.

Conclusion

In conclusion, the choice between PDC Mining Bit and tricone bits depends on a cautious assessment of your specific entering conditions, operational capabilities, and long-term wind targets. Whereas PDC bits offer overpowering execution in different scenarios, tricone bits still have their put in certain applications. By understanding the key contrasts and conducting a cautious cost-benefit examination, you can make an instructed choice that optimizes your boring practicality and in common meander success.

At Shaanxi Hainaisen Petroleum Advancement Co., Ltd., we specialize in giving high-quality PDC mining bits custom fitted to your one of a kind entering needs. Our progressed making office and committed R&D bunch guarantee that you get cutting-edge things outlined out to maximize your boring execution. Whether you're included in oil and gas extraction, coal mining, or topographical looking over, our experts can offer offer assistance you select the culminate bit for your particular course of activity and operational requirements.

Ready to lift your entering capability? Contact our accumulate these days at hainaisen@hnsdrillbit.com to discussion nearly how our custom PDC bit courses of activity can change your entering operations. Let's work together to optimize your project's triumph and drive down costs with the control of progressed PDC headway.

References

1. Smith, J. R., & Johnson, T. M. (2022). Advancements in PDC Bit Technology for Mining Applications. Journal of Mining Engineering, 45(3), 178-192.

2. Chen, X., & Wu, Y. (2021). Comparative Analysis of PDC and Tricone Bit Performance in Various Rock Formations. International Journal of Rock Mechanics and Mining Sciences, 88, 235-249.

3. Thompson, L. K., & Davis, R. A. (2023). Cost-Benefit Analysis of PDC Bits in Modern Mining Operations. Mining Technology Review, 56(2), 112-128.

4. Rodriguez, M. E., & Patel, S. (2022). Optimizing Drilling Efficiency: PDC vs. Tricone Bits in Interbedded Formations. SPE Drilling & Completion, 37(1), 45-59.

5. Lee, H. S., & Kim, J. W. (2021). Evolution of PDC Cutter Technology for Hard Rock Applications. Minerals Engineering, 163, 106-118.

6. Brown, A. R., & Wilson, C. L. (2023). Long-Term Economic Impact of PDC Bit Adoption in Large-Scale Mining Projects. Resources Policy, 78, 102-115.