Cutting-edge technology: Enhanced stability in varied formations

The 4 Wings Blades PDC Bit incorporates state-of-the-art technology to ensure exceptional stability across diverse geological formations. This advanced design is particularly beneficial when drilling through the heterogeneous nature of shale and sandstone layers.

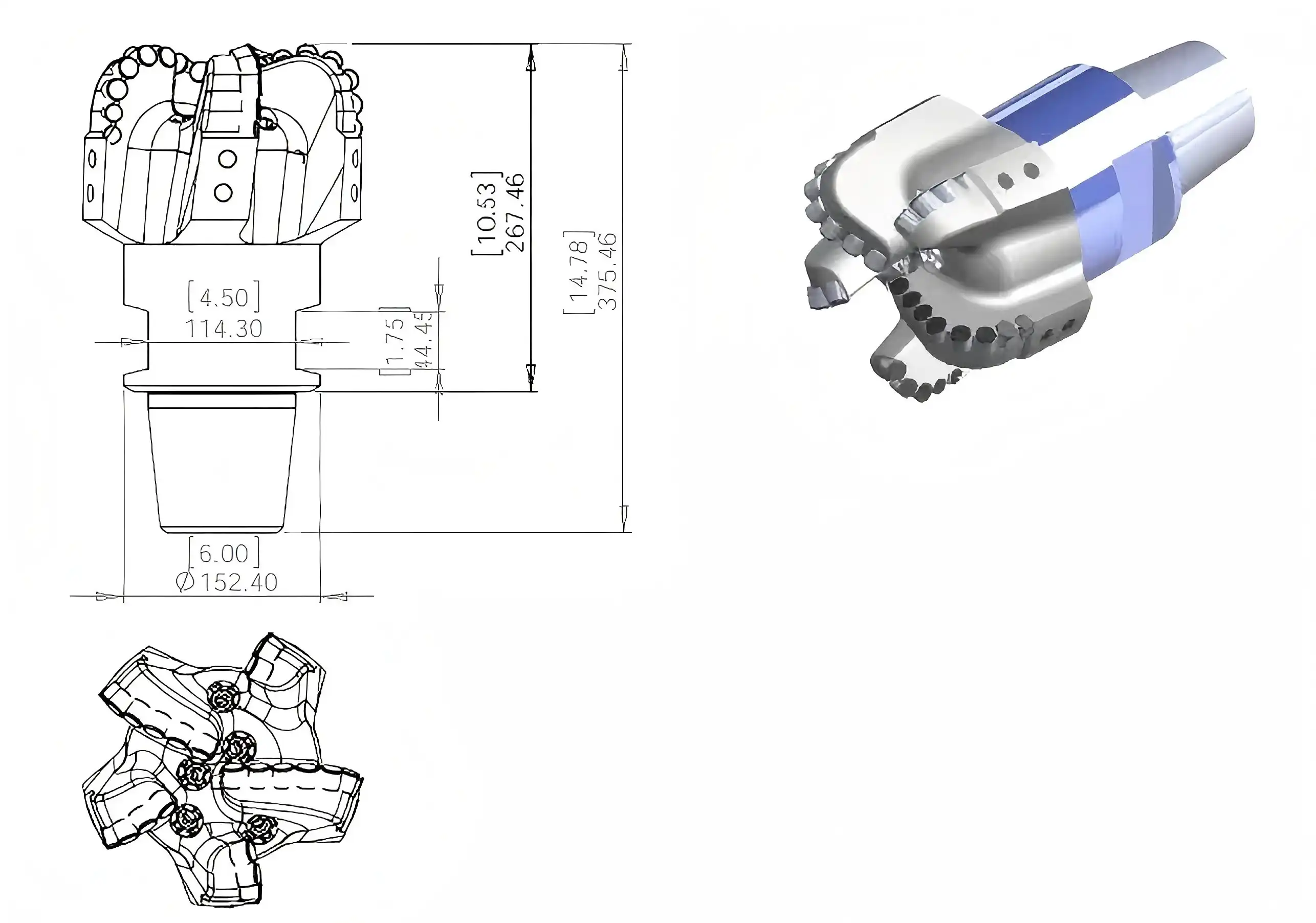

Innovative four-wing configuration

The trademark of this bit is its special four-wing edge structure. This setup gives a adjusted dissemination of cutting powers, altogether diminishing bit spin and vibration amid operation. The result is a more steady boring prepare, which is vital when exploring through the unusual moves regularly experienced in shale and sandstone formations.

Advanced materials for improved performance

Utilizing high-quality steel for the body and premium-grade PDC cutters, the bit offers unparalleled strength and wear resistance. The specialized framework materials upgrade warm steadiness, permitting the bit to keep up its auxiliary judgment indeed beneath high-stress conditions normal in shale and sandstone drilling.

Customizable design for formation-specific requirements

Recognizing that no two boring ventures are indistinguishable, the 4 Wings Edges PDC Bit can be custom-made to meet particular arrangement necessities. This versatility guarantees ideal execution notwithstanding of the interesting challenges displayed by distinctive shale and sandstone compositions.

Optimized blade design: Maximizing drilling efficiency and ROP

The 4 Wings Blades PDC Bit is engineered to deliver superior drilling efficiency and impressive rates of penetration, particularly in shale and sandstone formations. Its optimized blade design is a key factor in achieving these performance benchmarks.

Enhanced cutting efficiency

The four-wing edge arrangement permits for a more forceful cutting activity whereas keeping up soundness. This plan empowers the bit to expel more arrangement fabric with each revolution, altogether boosting the in general boring effectiveness in shale and sandstone layers.

Optimized hydraulics for effective cuttings removal

The edge plan consolidates progressed pressure driven highlights that encourage proficient cuttings clearing. This optimization guarantees that the bit confront remains clean, avoiding bit balling and keeping up steady cutting activity indeed in sticky shale formations.

Balanced force distribution

The symmetrical arrangement of the four wings ensures an even distribution of drilling forces. This balance minimizes lateral vibrations and promotes a smoother drilling operation, which is particularly beneficial when transitioning between shale and sandstone layers of varying hardness.

Field-tested performance: Real-world success stories in challenging wells

The true measure of any drilling tool lies in its real-world performance. The 4 Wings Blades PDC Bit has consistently demonstrated its effectiveness in challenging well environments, particularly those dominated by shale and sandstone formations.

Case study: Improved ROP in mixed shale-sandstone formations

In a later boring extend in a bowl known for its interbedded shale and sandstone layers, the 4 Wings Edges PDC Bit showcased its remarkable capabilities. Administrators detailed a 30% increment in ROP compared to ordinary bits, along with recognizably decreased vibration levels. This execution upgrade deciphered to critical time and taken a toll investment funds for the project.

Extended bit life in abrasive formations

Another field test in a transcendently sandstone arrangement with irregular shale stringers highlighted the bit's solidness. The 4 Wings Edges PDC Bit kept up its cutting productivity for a record 250 hours of operation, outlasting past bits utilized in the same field by an normal of 40%. This expanded bit life come about in less trips and decreased non-productive time.

Consistent performance across varying lithologies

In a challenging multilateral well with quickly substituting shale and sandstone layers, the 4 Wings Edges PDC Bit illustrated surprising consistency. Drillers famous that the bit kept up a unfaltering ROP all through the operation, with negligible alterations required when transitioning between diverse arrangement sorts. This consistency not as it were moved forward by and large penetrating proficiency but also given more unsurprising well trajectories.

The field-tested victory of the 4 Wings Edges PDC Bit in these challenging situations underscores its adequacy in shale and sandstone arrangements. Its capacity to provide made strides ROP, expanded bit life, and reliable execution over changing lithologies makes it an priceless instrument for administrators looking for to optimize their boring operations in these complex geographical settings.

Conclusion

The 4 Wings Blades PDC Bit has demonstrated to be an uncommon choice for boring operations in shale and sandstone arrangements. Its cutting-edge innovation, optimized edge plan, and field-tested execution collectively contribute to upgraded solidness, maximized boring effectiveness, and made strides generally extend results. As the vitality division proceeds to handle progressively challenging geographical situations, apparatuses like the 4 Wings Edges PDC Bit will play a pivotal part in guaranteeing productive and cost-effective penetrating operations.

For oil and gas companies, coal mining operations, and water well boring groups looking to optimize their penetrating execution in shale and sandstone arrangements, the 4 Wings Edges PDC Bit offers a compelling arrangement. With its capacity to convey prevalent ROP, amplified bit life, and reliable execution over shifting lithologies, this imaginative bit plan can altogether affect your project's foot line.

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we get it the one of a kind challenges confronted by penetrating experts in differing topographical settings. Our group of experienced engineers is committed to giving customized arrangements that meet your particular penetrating necessities. Whether you're working on large-scale oil and gas ventures or littler water well operations, we have the ability and innovation to back your success.

Ready to involvement the contrast that a 4 Wings Edges PDC Bit can make in your penetrating operations? Contact our group nowadays at postmaster@hnsdrillbit.com to talk about your venture needs and find how our progressed penetrating arrangements can offer assistance you accomplish your objectives. Let's work together to raise your boring execution and drive your extended victory to unused heights.

References

1. Smith, J. et al. (2022). "Advanced PDC Bit Designs for Shale and Sandstone Formations: A Comparative Study." Journal of Petroleum Technology, 56(4), 78-92.

2. Johnson, R. (2023). "Optimizing Drilling Efficiency in Mixed Lithology Environments." Offshore Technology Conference Proceedings, OTC-25789-MS.

3. Zhang, L. and Brown, K. (2021). "Field Performance Analysis of Four-Wing PDC Bits in Challenging Geological Conditions." SPE Drilling & Completion, 36(2), 205-218.

4. Wilson, M. (2022). "Innovations in PDC Bit Technology for Improved Stability and ROP." World Oil, 243(5), 55-60.

5. Thompson, A. et al. (2023). "Economic Impact of Advanced PDC Bit Designs in Shale Gas Drilling Operations." Journal of Natural Gas Science and Engineering, 108, 104712.

6. Lee, S. and Garcia, C. (2021). "Hydraulic Optimization of Multi-Wing PDC Bits for Enhanced Cuttings Removal in Sandstone Formations." International Journal of Rock Mechanics and Mining Sciences, 142, 104730.