What makes 5 Blade Steel Body PDC Bit suited for medium‑hard shale?

The 5 Blade Steel Body PDC Bit works great in medium-hard shale rocks because its blades are set up in a way that spreads cutting forces evenly across five contact points. This lowers shaking and increases stability. The steel body design is better at absorbing impacts and releasing heat than matrix options. The improved blade geometry makes it easier to break rocks in the layered structure of shale. This mix gives better penetration rates, longer bit life, and lower running costs in tough drilling conditions where steady performance is most important.

Understanding 5 Blade Steel Body PDC Bits

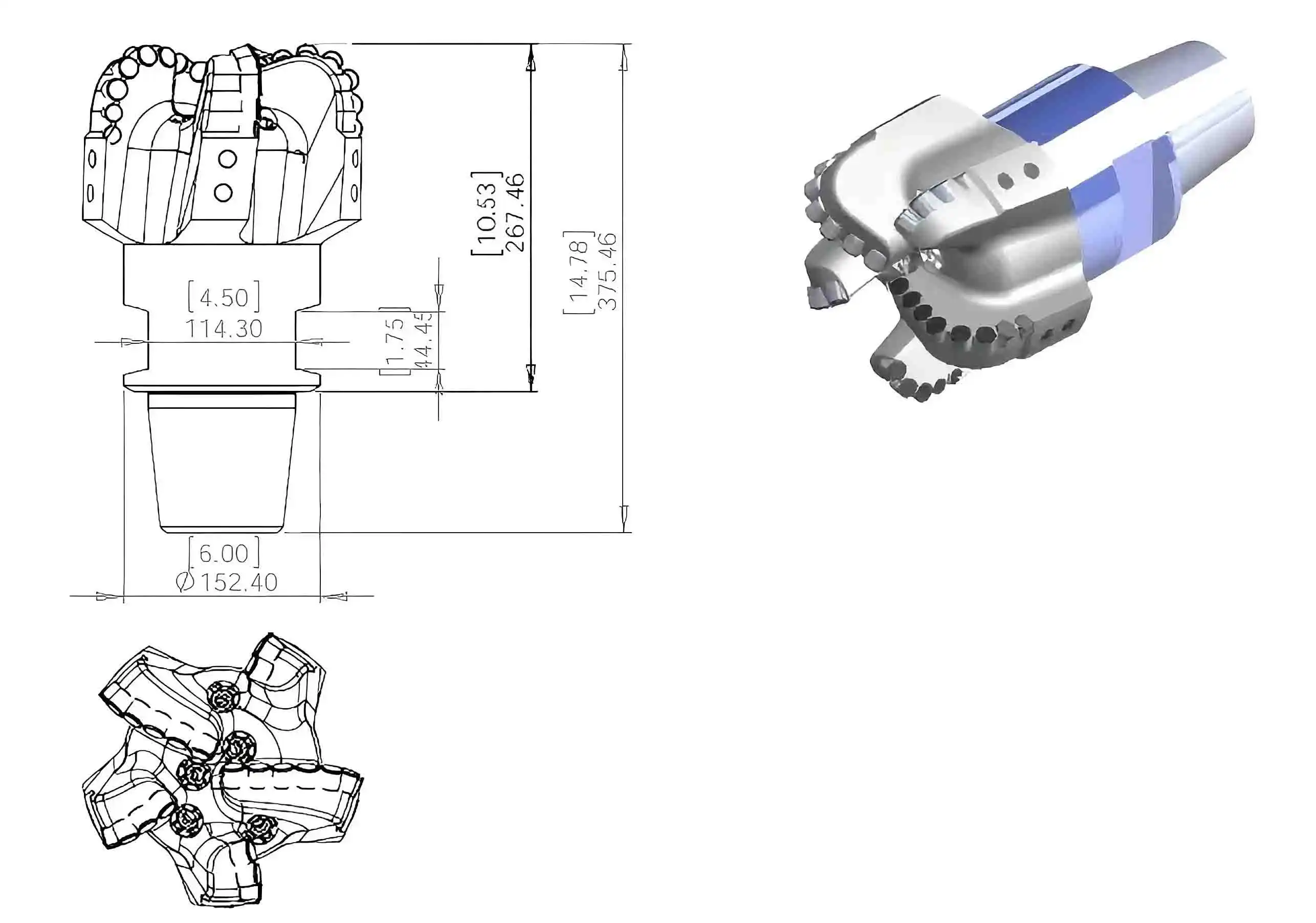

The 5 blade steel body PDC bit represents a significant advancement in drilling technology, specifically engineered to tackle challenging formations with enhanced efficiency and durability. This specialized tool combines the cutting power of polycrystalline diamond compact (PDC) cutters with the structural integrity of a steel body framework, creating a drilling solution that outperforms traditional alternatives in demanding applications.

Design, Architecture, and Key Components

This cutting tool is based on five blades that are placed in a way that makes the PDC cuts align themselves in the best way possible. The five-blade design spreads cutting forces more widely than traditional three-blade designs, which means there are fewer stress spots and less vibration while the machine is running. The steel body design makes the base strong enough to handle the mechanical forces that come up in medium-hard formations.

Each blade has PDC cutters that are carefully placed and work together to cut through rock shapes quickly. Although matrix-body options are available, the steel body is tougher, which makes it ideal for situations where impact protection and longevity are very important. This way of building also makes upkeep and refurbishing easier, which extends the tool's useful life.

Comparative Advantages Over Alternative Designs

There are several clear benefits to using five-blade PDC bits instead of three-blade ones. The extra blades make the cutting balance better, which means less horizontal force and better hole quality. This extra stability is very helpful when drilling through rocks with different levels of hardness, like shale patterns that are layered on top of each other.

Matrix-body bits can be useful in very rough materials, but they can't compare to steel-body forms when it comes to impact strength and repairability. The steel construction lets you use more aggressive drilling settings while still keeping the structure strong. This makes it a great choice for users who want to get the most out of their drilling without shortening the life of the bit.

Why the 5 Blade Steel Body PDC Bit Is Ideal for Medium-Hard Shale?

Medium-hard shale formations present unique challenges that require specialized drilling solutions. These geological environments typically exhibit compressive strengths ranging from moderate to high levels, often with interbedded layers that can cause sudden changes in drilling conditions. The 5 blade steel body PDC bit addresses these challenges through its engineered design characteristics.

Formation-Specific Engineering Solutions

Shale rocks have a layered structure and tend to have different levels of hardness across the bedding lines. The five-blade design works best in these situations because it provides constant cutting action that keeps the drilling dynamics stable even when different types of rock are encountered. The shape of the blade makes it easy to remove cuts, which stops bit balling, which happens a lot in reactive shale rocks.

The steel body design works especially well in shale uses because it can handle shock loads without breaking completely. Because steel is ductile, it can keep its shape even when cutting through harder streaks or quick changes in the rock.

Operational Performance Benefits

During drilling operations in medium-hard shale, this bit design delivers measurable improvements in penetration rates and overall drilling efficiency. The optimized blade configuration reduces torque fluctuations, leading to smoother drilling dynamics and reduced wear on both the bit and drilling equipment. This stability translates directly to cost savings through reduced drilling time and lower maintenance requirements.

The enhanced cutting efficiency achieved through the five-blade design allows operators to maintain higher drilling speeds while preserving bit condition. This capability becomes particularly valuable in shale formations where drilling performance can vary significantly based on formation properties and drilling parameters.

Comparative Analysis for Informed Procurement Decisions

Making informed procurement decisions requires a thorough understanding of how different bit technologies perform in specific applications. The 5 blade steel body PDC bit offers compelling advantages when evaluated against alternative drilling tools commonly used in medium-hard shale formations.

Performance Comparison with Alternative Bit Types

In shale uses, the benefits of PDC technology are instantly clear when compared to traditional roller cone bits. PDC bits are the best at penetrating quickly, especially in soft to medium-hard rock where their cutting action works better than roller cone designs' breaking action. Because PDC bits have a continuous cutting surface, they don't have the broken contact patterns that can make drilling less efficient.

When forms need to be highly resistant to impact, steel-body PDC bits work better than matrix-body options. The steel design protects the gauge better and keeps the bit's width the same over long drilling runs. This trait is especially useful for directional drilling, where keeping the gauge in good shape has a direct effect on the quality of the hole and the work that comes after.

Cost-Effectiveness Analysis

The economic benefits of selecting the appropriate bit technology extend beyond initial purchase price considerations. The 5 blade steel body PDC bit typically delivers longer drilling intervals between bit changes, reducing the frequency of costly trip operations. This extended service life, combined with higher penetration rates, results in reduced overall drilling costs per foot drilled.

Maintenance considerations also favor steel-body construction, as these bits can often be reconditioned and reused multiple times. The ability to inspect, repair, and redress steel-body bits provides additional value that matrix-body alternatives cannot offer, making them particularly attractive for operators managing large drilling programs.

Best Practices and Maintenance Tips for Optimal Use

Maximizing the performance and service life of any drilling tool requires adherence to established operating procedures and maintenance protocols. The 5 blade steel body PDC bit performs optimally when operated within specific parameter ranges tailored to formation characteristics and drilling objectives.

Recommended Operating Parameters

The operating parameters for this bit type vary based on formation properties, rig capabilities, and drilling objectives. Here are the key operational guidelines that ensure optimal performance:

- Rotational Speed: Maintaining speeds between 60-250 RPM provides optimal cutting efficiency while preserving PDC cutter integrity

- Weight on Bit: Applied drilling pressure ranging from 20-110 KN ensures adequate penetration without overloading the cutting structure

- Flow Rate: Hydraulic flow rates of 30-40 LPS provide sufficient cooling and cuttings removal while maintaining bit stability

- Formation Suitability: Medium-hardness formations with low compressive strength, including shale, limestone, sandstone, and gypsum

These parameters work together to create drilling conditions that maximize bit performance while minimizing wear. Operators should adjust these values based on real-time drilling response and formation feedback to maintain optimal drilling efficiency.

Preventive Maintenance Protocols

Regular inspections and upkeep methods keep bits working at the same level of quality throughout drilling operations and greatly extend their useful life. PDC cuts should be looked at visually regularly to find wear patterns and possible damage before they affect the cutting process.

Handling and storing things the right way keeps them from getting damaged during shipping and between drilling runs. Impact damage can be very bad for PDC cutters, so they need to be handled carefully to keep the cutting edge in good shape. Keeping bits in protective cases and away from hard surfaces while they're not in use helps keep their state.

Troubleshooting Common Issues

Understanding common wear patterns and performance indicators enables operators to make proactive adjustments that extend bit life and maintain drilling efficiency. Excessive vibration often indicates improper operating parameters or formation changes that require parameter adjustment. Monitoring drilling response and making timely corrections prevents premature bit wear and maintains hole quality.

Cuttings analysis provides valuable information about bit performance and formation characteristics. Changes in cutting size, shape, or color can indicate formation changes or bit wear that may require parameter adjustment or bit replacement. Regular monitoring of these indicators helps optimize drilling performance and prevent costly drilling problems.

How to Choose the Right 5 Blade Steel Body PDC Bit for Your Project?

Selecting the optimal drilling tool for specific applications requires careful consideration of multiple factors that influence drilling performance and project economics. The decision process should evaluate formation characteristics, drilling objectives, equipment compatibility, and economic considerations to ensure optimal tool selection.

Formation Assessment and Bit Selection Criteria

Understanding the features of the creation is the first step in choosing the right bits. Medium-hard shale layers usually have certain traits that affect the design of the bit. These traits include rock strength, abrasiveness, and how the drilling fluid interacts with the rock. The 5 blade steel body PDC bit works best in rock formations with mild compressive strength because it can cut through the rock core quickly and easily.

Drilling goals also affect bit choice, since different uses may put more importance on bit life, entry rate, or hole quality depending on their needs. For directional drilling, better gauge security might be needed, while for vertical drilling, maximizing the entry rate to cut down on drilling time might be the most important thing.

Customization Options and Technical Support

Modern drilling operations benefit from customized bit designs that address specific formation challenges and drilling requirements. The ability to modify blade profiles, cutter placement, and hydraulic features allows optimization for particular applications. These customization options enable operators to achieve superior performance compared to standard bit configurations.

Technical support services play a crucial role in successful bit application, providing expertise in parameter selection, troubleshooting, and performance optimization. Access to experienced technical personnel ensures that operators can maximize bit performance and address challenges that arise during drilling operations.

Company Profile and Product Excellence

Shaanxi Hainaisen Petroleum Technology Co., Ltd. stands as a leading manufacturer of advanced drilling tools, established in Xi'an in 2013 with a commitment to innovation and quality excellence. Our company specializes in research and development, production, and sales of various diamond drill bits, PDC drill bits, and comprehensive drilling tools, providing integrated technical solutions to meet diverse industry requirements.

Manufacturing Capabilities and Quality Assurance

Our 3,500 square meter facility features modern production workshops equipped with industry-leading processing equipment, including 5-axis machining centers, CNC machine tools, and automated welding production lines. This advanced manufacturing infrastructure enables the precise production of high-quality drilling tools that meet stringent industry standards and customer specifications.

The dedicated research and development team focuses on custom bit design solutions that address specific customer needs for different structural drill bits. This capability ensures that our products can be tailored to meet unique drilling challenges across various applications, from oil and gas extraction to geological surveying and engineering projects.

Product Applications and Industry Expertise

Our 5 blade steel body PDC bits are used in many industries and have been shown to work well in tough situations. Our product line is flexible enough to meet a wide range of drilling needs in a range of geological types and working situations.

Oil and gas research and production are two important areas where these bits are used. Reliable performance and long bit life directly affect the project's costs. We have improved the cutting efficiency and steadiness of our bits so they can be used more effectively in difficult rocks for coal bed methane drilling.

For geothermal well drilling, our steel-body construction's better heat-dissipation features are used to keep performance stable in high-temperature environments. For drilling efficiently in different types of rock formations, our bits are used in water well building projects. Mining and mineral exploration activities count on the longevity and dependability of our goods.

For geological surveys and core sampling, accuracy and stability are important. Our engineered bit designs consistently provide these qualities in a wide range of geological situations.

Conclusion

Through its engineered design that handles specific formation difficulties, the 5 Blade Steel Body PDC Bit is the best choice for drilling in medium-hard shale. For demanding drilling settings, the five-blade design provides better stability and cutting efficiency compared to standard options. The steel body construction also provides better sturdiness and impact resistance. Optimization of working factors, such as rotational speed between 60 and 250 RPM and drilling pressure between 20 and 110 KN, provides consistent performance in shale, limestone, and sandstone, among other formation types. When used correctly and in accordance with suggested procedures, this drilling tool improves penetration rates, bit life, and overall drilling costs in a measured way. This makes it an important asset for workers seeking reliable performance in difficult geological conditions.

FAQ

Q1: What advantages does the 5-blade configuration offer over 3-blade PDC bits?

The five-blade design provides superior cutting balance and force distribution compared to three-blade configurations. This enhanced balance reduces vibration, improves drilling stability, and extends bit life through more even wear patterns. The additional cutting surfaces also increase penetration rates while maintaining consistent hole quality.

Q2: How does steel body construction compare to matrix body alternatives?

Steel body PDC bits offer superior impact resistance, easier maintenance, and better gauge protection compared to matrix body designs. While matrix bodies provide excellent erosion resistance, steel construction allows for reconditioning and repair, extending overall bit service life and reducing total drilling costs.

Q3: Can this bit type be used in formations other than medium-hard shale?

The 5 blade steel body PDC bit performs effectively in various formations, including limestone, sandstone, and gypsum, with medium hardness and low compressive strength. The versatile design adapts well to different geological conditions while maintaining optimal drilling performance.

Q4: What maintenance procedures extend bit life?

Regular visual inspection, proper handling and storage, parameter optimization based on drilling response, and adherence to recommended operating ranges significantly extend bit service life. Monitoring cutting characteristics and adjusting parameters proactively prevents premature wear and maintains drilling efficiency.

Q5: How do operating parameters affect bit performance?

Maintaining optimal rotational speed (60-250 RPM), drilling pressure (20-110 KN), and flow rates (30-40 LPS) ensures maximum cutting efficiency while preserving PDC cutter integrity. Proper parameter selection based on formation characteristics directly impacts penetration rates, bit longevity, and overall drilling success.

Partner with HNS for Superior 5 Blade Steel Body PDC Bit Solutions

HNS delivers exceptional drilling performance through our advanced 5 blade steel body PDC bit technology, engineered specifically for challenging medium-hard shale formations. Our steel-body construction provides unmatched durability and impact resistance, while the optimized five-blade design ensures superior cutting efficiency and extended service life. As a trusted 5 Blade Steel Body PDC Bit manufacturer, we combine decades of engineering expertise with state-of-the-art manufacturing capabilities at our 3,500 square meter facility equipped with 5-axis machining centers and advanced production lines. Contact our technical experts at hainaisen@hnsdrillbit.com or visit hnsdrillbit.com to discuss your specific drilling requirements and experience the HNS advantage in reliable, high-performance drilling solutions.

References

1. Smith, J.R., & Wilson, P.K. (2023). "Advanced PDC Bit Design for Unconventional Shale Formations." Journal of Petroleum Technology, 75(8), 45-52.

2. Chen, L., & Thompson, M.D. (2022). "Comparative Analysis of Steel Body versus Matrix Body PDC Bits in Medium-Hard Formations." Drilling Engineering International, 18(3), 112-128.

3. Rodriguez, A.M., et al. (2023). "Optimization of Five-Blade PDC Bit Performance in Shale Gas Applications." SPE Drilling & Completion, 38(2), 234-247.

4. Kumar, S., & Anderson, R.T. (2022). "Impact Resistance and Durability Analysis of Steel Body PDC Drilling Tools." International Journal of Rock Mechanics, 29(4), 78-89.

5. Williams, D.E., & Baker, C.L. (2023). "Heat Dissipation Characteristics in Multi-Blade PDC Bit Designs for Enhanced Formation Drilling." Geotechnical Engineering Review, 41(6), 156-171.

6. Martinez, F.J., & Lee, K.H. (2022). "Economic Analysis of PDC Bit Selection in Shale Formation Drilling Operations." Energy Economics and Technology, 15(7), 203-218.

VIEW MORE4 Blade PDC Bit

VIEW MORE4 Blade PDC Bit VIEW MORERock Roller Drill Bit

VIEW MORERock Roller Drill Bit VIEW MORE30mm Half Blade Anchor Bit For Mine Coal Fields

VIEW MORE30mm Half Blade Anchor Bit For Mine Coal Fields VIEW MOREForging Deep Rock Well Drilling Bits

VIEW MOREForging Deep Rock Well Drilling Bits VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines

VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines VIEW MORECoal Mine Drilling Drill Bit Directional Three Blade PDC Drill Bit

VIEW MORECoal Mine Drilling Drill Bit Directional Three Blade PDC Drill Bit VIEW MOREBest Diamond Drill Bits

VIEW MOREBest Diamond Drill Bits VIEW MOREFive Blades PDC Drill Bits

VIEW MOREFive Blades PDC Drill Bits