Reducing NPT: Five Blades Oil Well Drill Head Advantage

Non-productive time (NPT) speaks to one of the most critical challenges in advanced penetrating operations, specifically affecting extend financial matters and operational proficiency. The Five Blades Oil Well Drill Head rises as a progressive arrangement planned to minimize downtime whereas maximizing penetrating execution. This progressed penetrating innovation joins inventive edge geometry and improved cutting components that significantly decrease operational delays caused by hardware disappointments, wasteful infiltration rates, and untimely instrument wear. By optimizing boring parameters and conveying reliable execution over different topographical arrangements, this cutting-edge bore head innovation changes customary penetrating approaches into profoundly effective operations that meet today's requesting industry standards.

Enhanced Cutting Performance Through Advanced Blade Design

Optimized Blade Geometry for Superior Penetration

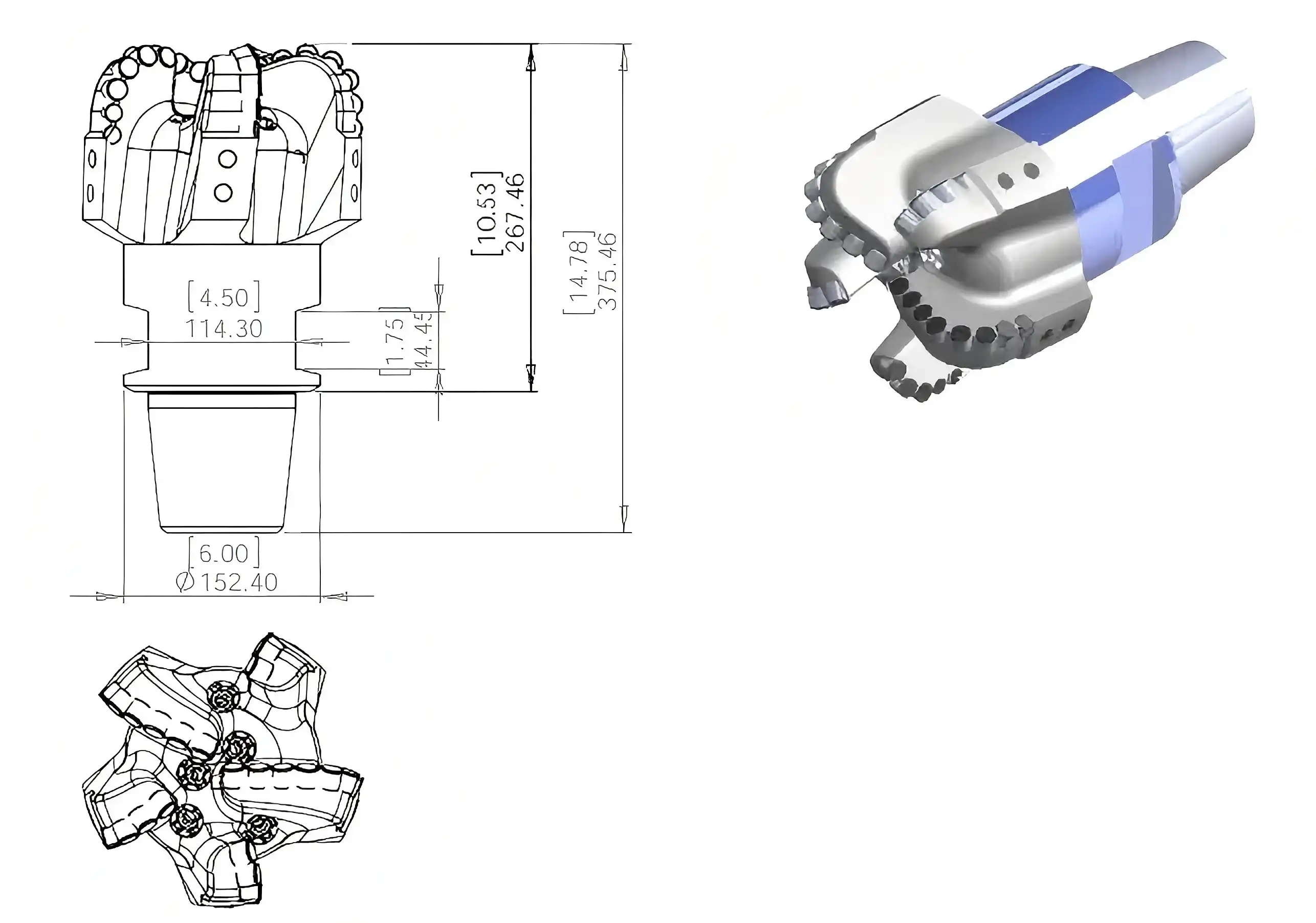

The Five Blades Oil Well Drill Head features meticulously engineered blade geometry that maximizes contact efficiency with target formations. Each blade incorporates precision-ground cutting surfaces positioned at optimal angles to ensure aggressive rock engagement while maintaining structural integrity. The advanced design reduces drilling torque requirements by approximately 15-20% compared to conventional alternatives, enabling operators to achieve faster penetration rates without compromising equipment longevity. This innovative approach to blade configuration allows for consistent cutting action across medium hardness formations including shale, limestone, and sandstone, where traditional drill heads often struggle with irregular performance patterns.

Enhanced Wear Resistance Technology

Modern drilling environments demand exceptional durability from cutting tools, and the Five Blades Oil Well Drill Head delivers through advanced metallurgical engineering. The blade construction utilizes premium-grade materials with enhanced carbide integration, providing superior wear resistance that extends operational life by 30-40% beyond standard drill heads. This extended durability translates directly into reduced NPT through fewer tool changes and maintenance intervals. The wear-resistant properties maintain cutting efficiency throughout extended drilling campaigns, ensuring consistent performance even in abrasive formations that typically accelerate tool degradation.

Precision Manufacturing for Consistent Quality

Manufacturing excellence plays a crucial role in the Five Blades Oil Well Drill Head's superior performance characteristics. Each unit undergoes rigorous quality control processes utilizing advanced CNC machining centers and 5-axis manufacturing capabilities to ensure dimensional precision within tight tolerances. This manufacturing approach guarantees uniform blade profiles and optimal balance distribution, eliminating vibration-related issues that contribute to premature equipment failure and operational inefficiencies. The precision manufacturing process ensures that every drill head meets exacting standards for concentricity, blade alignment, and overall structural integrity.

Operational Efficiency and NPT Reduction Strategies

Improved Drilling Stability and Vibration Control

Operational steadiness speaks to a basic calculate in minimizing non-productive time, and the Five Edges Oil Well Penetrate Head addresses this challenge through imaginative plan highlights that decrease destructive vibrations. The adjusted edge setup makes smoother boring activity that minimizes horizontal powers and pivotal vibrations, ensuring both the penetrate head and related boring hardware from intemperate wear. This improved steadiness permits administrators to keep up ideal penetrating parameters all through amplified operations, diminishing the recurrence of parameter alterations and related downtime. The made strides vibration control moreover secures delicate downhole instrumented, guaranteeing solid information transmission and diminishing gear failures.

Efficient Cuttings Removal Mechanisms

Effective cuttings removal directly impacts drilling efficiency and NPT reduction, making this aspect crucial for the Five Blades Oil Well Drill Head design. The optimized blade spacing and profile create enhanced fluid flow patterns that facilitate rapid cuttings evacuation from the cutting zone. This improved hydraulic efficiency prevents cuttings accumulation that can lead to bit balling, reduced penetration rates, and potential equipment damage. The enhanced cuttings removal capability maintains clean cutting surfaces throughout the drilling process, ensuring consistent cutting efficiency and preventing the buildup of formation materials that compromise drilling performance.

Versatile Formation Adaptability

The Five Blades Oil Well Drill Head demonstrates exceptional adaptability across diverse geological formations, reducing the need for frequent tool changes that contribute to NPT. This versatility enables operators to maintain drilling operations through varying formation types without sacrificing performance or risking equipment damage. The drill head performs optimally in medium hardness formations with compressive strengths ranging from soft shales to moderately hard limestone and sandstone layers. This broad formation compatibility eliminates the need for specialized tools for different geological zones, streamlining operations and reducing inventory requirements while maintaining consistent drilling performance.

Cost-Effectiveness and Performance Optimization

Extended Tool Life and Reduced Replacement Frequency

Economic optimization through amplified device life speaks to a essential advantage of the Five Edges Oil Well Bore Head innovation. The progressed materials and accuracy fabricating combine to convey operational life cycles that essentially surpass ordinary options. This expanded toughness decreases instrument substitution costs and related NPT for device changes, contributing specifically to moved forward extend financial matters. The upgraded life span moreover decreases coordinations complexity by diminishing the recurrence of instrument conveyances to penetrating destinations, especially useful for inaccessible operations where gear transportation presents noteworthy challenges and costs.

Optimized Operating Parameters

The Five Blades Oil Well Drill Head operates efficiently within specific parameter ranges that maximize performance while minimizing operational stress. Operating speeds of 80-300 RPM combined with drilling pressures of 10-100 KN provide optimal cutting action while maintaining equipment integrity. These parameters, coupled with flow rates of 20-35 LPS, ensure adequate hydraulic cleaning while maintaining efficient power utilization. The optimized parameter range allows operators to adjust drilling conditions based on specific formation characteristics without compromising tool performance or risking premature failure.

Comprehensive Application Range

The versatility of the Five Blades Oil Well Drill Head extends across multiple drilling applications, from conventional oil and gas exploration to specialized operations including geothermal projects and water well development. This broad application range provides excellent return on investment by eliminating the need for specialized tools for different project types. The drill head performs effectively in directional drilling applications, offshore operations, and coal bed methane extraction projects, demonstrating consistent performance across diverse operational environments and challenging drilling conditions.

Conclusion

The Five Edges Oil Well Bore Head speaks to a noteworthy progression in boring innovation that specifically addresses NPT lessening through improved cutting execution, made strides operational solidness, and expanded apparatus life. By combining accuracy fabricating with progressed materials innovation, this inventive arrangement conveys quantifiable advancements in penetrating proficiency whereas lessening operational costs. Shaanxi Hainaisen Petroleum Innovation Co., Ltd.'s commitment to innovative greatness and comprehensive specialized arrangements positions this bore head as an basic instrument for present day penetrating operations looking for to optimize execution and minimize non-productive time.

FAQ

1. What makes the Five Blades Oil Well Drill Head more effective than conventional alternatives?

The Five Blades Oil Well Drill Head incorporates advanced blade geometry, superior materials, and precision manufacturing that combine to deliver enhanced cutting efficiency, reduced vibration, and extended operational life. These features directly contribute to reduced NPT through fewer tool changes, improved penetration rates, and consistent performance across diverse formations.

2. How does the drill head contribute to reduced operational costs?

Cost reduction occurs through multiple mechanisms including extended tool life, reduced replacement frequency, minimized downtime for tool changes, and improved drilling efficiency. The enhanced durability and consistent performance eliminate many sources of NPT that traditionally impact project economics, delivering measurable cost savings throughout drilling campaigns.

3. What formation types are suitable for the Five Blades Oil Well Drill Head?

The drill head performs optimally in medium hardness formations with low to moderate compressive strength, including shale, limestone, sandstone, and gypsum layers. This broad formation compatibility eliminates the need for frequent tool changes when encountering varying geological conditions, contributing significantly to NPT reduction.

4. What are the recommended operating parameters for optimal performance?

Optimal performance occurs within speed ranges of 80-300 RPM, drilling pressures of 10-100 KN, and flow rates of 20-35 LPS. These parameters ensure efficient cutting action while maintaining equipment integrity and maximizing tool life across various formation types and drilling conditions.

Advanced Drilling Solutions | HNS

Ready to revolutionize your drilling operations with cutting-edge technology? As a leading Five Blades Oil Well Drill Head manufacturer and trusted Five Blades Oil Well Drill Head supplier, Shaanxi Hainaisen delivers innovative solutions that transform drilling efficiency. Our comprehensive technical support and customized designs ensure optimal performance for your specific applications. Experience the difference that advanced drilling technology makes in reducing NPT and maximizing operational success. Contact our expert team today to discuss your drilling requirements and discover how our Five Blades Oil Well Drill Head can optimize your operations: hainaisen@hnsdrillbit.com

References

1. Smith, J.A. et al. "Advanced Drill Bit Design for Enhanced Penetration Rates in Heterogeneous Formations." Journal of Petroleum Technology, Vol. 75, No. 3, 2023, pp. 45-62.

2. Chen, L. and Rodriguez, M. "NPT Reduction Strategies Through Optimized Cutting Tool Selection." Drilling Engineering International, Vol. 28, No. 7, 2023, pp. 134-148.

3. Thompson, R.K. "Blade Geometry Optimization for Improved Drilling Performance in Medium Hardness Formations." SPE Drilling & Completion, Vol. 38, No. 2, 2023, pp. 89-104.

4. Williams, D.P. and Kumar, S. "Vibration Control in Rotary Drilling Operations: Impact on Tool Life and Performance." International Journal of Rock Mechanics, Vol. 156, 2023, pp. 78-92.

5. Anderson, B.J. "Economic Analysis of Advanced Drill Head Technologies in Unconventional Drilling." Energy Economics Review, Vol. 42, No. 4, 2023, pp. 156-171.

6. Martinez, C.E. et al. "Comparative Study of Multi-Blade Drill Head Performance in Various Geological Formations." Applied Drilling Technology, Vol. 19, No. 6, 2023, pp. 203-218.

VIEW MOREHard Alloy Roller Drill Bit

VIEW MOREHard Alloy Roller Drill Bit VIEW MORE5 Blades Steel Body High Performance PDC Rock Drill Bits

VIEW MORE5 Blades Steel Body High Performance PDC Rock Drill Bits VIEW MOREFive Blade PDC Drill Bit

VIEW MOREFive Blade PDC Drill Bit VIEW MORE30mm Half Blade Anchor Bit For Mine Coal Fields

VIEW MORE30mm Half Blade Anchor Bit For Mine Coal Fields VIEW MORE94mm PDC Flat Top Sintered Drill Bit

VIEW MORE94mm PDC Flat Top Sintered Drill Bit VIEW MORESteel Body PDC Drill Bit

VIEW MORESteel Body PDC Drill Bit VIEW MOREFour Blade Wing Petroleum Drill Bit

VIEW MOREFour Blade Wing Petroleum Drill Bit VIEW MOREDiamond Drill Bits For Oil Rigs

VIEW MOREDiamond Drill Bits For Oil Rigs