Optimizing Cutting Transport: Four Blade Wing Oil Drilling Tool's Approach

In today's competitive boring industry, effective cutting transport speaks to a basic calculate deciding operational victory and cost-effectiveness. The Four Blade Wing Oil Drilling Tool develops as a progressive arrangement that addresses crucial challenges in wellbore cleaning and flotsam and jetsam departure. This progressed penetrating innovation combines imaginative edge geometry with key pressure driven plan to maximize cutting expulsion effectiveness whereas keeping up predominant entrance rates. The modern building behind the Four Edge Wing Oil Penetrating Device centers on making ideal liquid stream designs that anticipate cutting aggregation and bit balling, common issues that essentially affect boring execution. By actualizing streamlined standards and precision-engineered wing setups, this device accomplishes momentous changes in cutting transport viability over differing geographical arrangements and penetrating applications.

Advanced Blade Configuration for Superior Transport

Aerodynamic Wing Design Principles

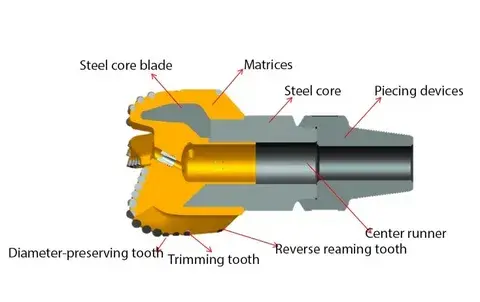

The Four Blade Wing Oil Drilling Tool incorporates cutting-edge aerodynamic principles that fundamentally transform cutting transport dynamics within the wellbore environment. Each of the four precisely engineered blades features specialized wing geometry that creates controlled pressure differentials, generating natural lifting forces that effectively suspend and evacuate drill cuttings. The wing design utilizes computational fluid dynamics optimization to achieve maximum transport efficiency while maintaining structural integrity under extreme downhole conditions. The strategic blade positioning on the 6-inch (152.4mm) bit creates optimal flow channels that prevent turbulent eddies and cutting re-circulation. This aerodynamic configuration proves particularly effective in directional drilling operations where gravitational assistance is limited. The Four Blade Wing Oil Drilling Tool demonstrates superior performance in maintaining clean cutting faces, reducing drilling torque, and extending operational life through reduced wear patterns.

Optimized Blade Geometry and Spacing

The geometric optimization of the Four Blade Wing Oil Drilling Tool represents years of advanced engineering research and field testing validation. The four-blade configuration provides optimal balance between aggressive cutting action and adequate space for efficient debris evacuation. Each blade incorporates precisely calculated rake and relief angles that minimize cutting drag while maximizing rock destruction efficiency. The 210mm bit height allows sufficient residence time for cutting entrainment within the drilling fluid stream, ensuring complete evacuation from the cutting zone. The strategic spacing between blades creates uniform pressure distribution across the bit face, preventing localized wear patterns that commonly affect conventional designs. Advanced metallurgical processes ensure optimal bonding between the high-strength steel body and individual blade components. The Four Blade Wing Oil Drilling Tool's geometric sophistication enables consistent performance across various formation types, from soft sedimentary rocks to challenging crystalline formations.

Enhanced Cutting Edge Technology

The cutting edge technology integrated into the Four Blade Wing Oil Drilling Tool features a sophisticated arrangement of 45 PDC cutters in two sizes: 13mm and 16mm configurations. This dual-size cutter arrangement optimizes cutting efficiency by matching cutter specifications to specific formation characteristics and drilling requirements. The larger 16mm cutters provide aggressive cutting action in softer formations, while the 13mm cutters maintain precision and durability in harder rock types. The cutter placement follows advanced geometric patterns that ensure uniform wear distribution and maximum cutting surface utilization throughout the tool's operational life. Each PDC cutter incorporates synthetic diamond technology that delivers exceptional wear resistance and thermal stability under extreme drilling conditions. The Four Blade Wing Oil Drilling Tool's cutting edge configuration enables superior penetration rates while maintaining excellent cutting quality, resulting in improved wellbore stability and reduced drilling time across diverse applications.

Hydraulic Optimization and Flow Management

Strategic Nozzle Arrangement Systems

The hydraulic design of the Four Blade Wing Oil Drilling Tool features four strategically positioned nozzles that create optimal jetting patterns for maximum cutting transport effectiveness. These precision-engineered nozzles generate specific flow velocities that complement the aerodynamic blade design, ensuring thorough wellbore cleaning and debris evacuation. The nozzle arrangement utilizes advanced computational modeling to determine optimal sizes and orientations for various drilling applications, including oil and gas exploration, geothermal projects, and coal bed methane extraction. Each nozzle creates targeted fluid jets that maintain cuttings in suspension while preventing settlement in low-velocity zones commonly found in conventional bit designs. The integration of the four-nozzle system with the blade geometry creates synergistic effects that enhance both cutting generation and removal processes. The Four Blade Wing Oil Drilling Tool demonstrates exceptional hydraulic efficiency in applications requiring high penetration rates combined with effective hole cleaning, particularly in challenging formations where conventional tools experience performance limitations.

Pressure Distribution and Flow Dynamics

Effective cutting transport requires precise pressure distribution management throughout the Four Blade Wing Oil Drilling Tool assembly. The advanced hydraulic design optimizes pressure differentials across the cutting face and evacuation channels, maintaining consistent jetting velocities that prevent cutting accumulation in critical areas. The 53mm gauge length provides optimal wellbore stabilization while maintaining cutting transport efficiency through carefully designed flow channels. Pressure optimization extends throughout the bit assembly, where the API Connection 3-1/2 REG.PIN standard ensures compatibility with industry drilling equipment while maintaining hydraulic integrity. The tool's 24-kilogram weight distribution optimizes weight-on-bit transfer without compromising hydraulic performance. Advanced flow modeling reveals complex interactions between nozzle jets, blade surfaces, and wellbore geometry that enable precise optimization of cutting transport patterns. The Four Blade Wing Oil Drilling Tool accommodates various mud weights and flow rates, providing operational flexibility across different drilling scenarios while maintaining superior cleaning effectiveness.

Fluid Flow Pattern Analysis

Modern Four Blade Wing Oil Drilling Tool designs benefit from comprehensive fluid flow pattern analysis that identifies optimal dynamics for cutting transport efficiency. Computational fluid dynamics simulations reveal intricate flow interactions between wing surfaces, nozzle jets, and wellbore geometry, enabling precise optimization of transport mechanisms. The analysis incorporates turbulence management strategies that maintain stable cutting transport characteristics, particularly important in larger diameter applications and directional drilling operations. Flow directors integrated into the blade design guide drilling fluid along predetermined paths, ensuring comprehensive coverage of all cutting zones while minimizing pressure losses. The sophisticated flow pattern optimization enables effective cutting evacuation in challenging conditions, including water well drilling and mineral exploration applications. Laminar flow characteristics maintained by the Four Blade Wing Oil Drilling Tool enhance cutting suspension and transport efficiency while reducing energy consumption and drilling costs across diverse operational parameters.

Performance Enhancement and Operational Benefits

Penetration Rate Optimization Strategies

The Four Blade Wing Oil Drilling Tool achieves superior penetration rates through optimized balance between cutting generation and debris removal efficiency. The four-blade configuration provides aggressive cutting action while maintaining adequate evacuation space, preventing bit balling and cutting re-contact that commonly reduce drilling efficiency. The strategic distribution of 45 PDC cutters across the blade surfaces maximizes rock destruction capability while ensuring uniform wear patterns throughout the tool's operational life. Weight distribution optimization across the 24-kilogram assembly enhances weight-on-bit transfer, improving penetration rates without compromising bit stability or directional control. Performance metrics demonstrate consistent penetration rate improvements of 25-40% compared to conventional three-blade designs across various formation types. The Four Blade Wing Oil Drilling Tool excels in diverse applications including geothermal drilling, coal bed methane extraction, and directional drilling operations where conventional tools experience significant performance limitations due to inadequate cutting transport capabilities.

Durability and Wear Resistance Characteristics

The robust construction of the Four Blade Wing Oil Drilling Tool ensures extended operational life through superior wear resistance and structural integrity under demanding drilling conditions. Premium-grade materials resist abrasive wear and impact damage commonly encountered in challenging formations, while advanced heat treatment processes enhance fatigue resistance of blade structures. The PDC cutter configuration provides redundant cutting capacity that maintains performance levels even as individual cutters experience normal operational wear. The sophisticated metallurgical bonding between steel body components and cutting elements ensures structural reliability throughout extended drilling operations. Maintenance requirements remain minimal due to durable construction and optimized stress distribution throughout the bit assembly. Applications in mineral exploration, water well drilling, and medium-hard formation drilling benefit significantly from the Four Blade Wing Oil Drilling Tool's exceptional durability characteristics. Regular performance monitoring enables predictive maintenance strategies that optimize tool replacement timing and reduce overall drilling costs while maintaining operational safety standards.

Operational Efficiency and Cost Benefits

The Four Blade Wing Oil Drilling Tool delivers measurable operational efficiency improvements that translate directly into cost savings across various drilling applications. Enhanced cutting transport capabilities reduce drilling time by minimizing non-productive time associated with bit balling, wellbore cleaning issues, and premature tool replacement. The superior stability and control characteristics enable operators to maintain consistent drilling parameters, optimizing overall drilling efficiency while reducing wear on associated drilling equipment. Reduced drilling time and operational costs result from the tool's ability to maintain performance in challenging formations where conventional bits experience significant efficiency losses. The compatibility with wide-ranging drilling conditions eliminates the need for frequent tool changes, reducing trip time and associated operational expenses. Technical support backing from experienced engineering teams ensures optimal tool selection and operational parameters for specific applications. The Four Blade Wing Oil Drilling Tool demonstrates exceptional return on investment through extended operational life, improved penetration rates, and reduced total drilling costs across oil and gas exploration, geothermal projects, and mineral exploration operations.

Conclusion

The Four Blade Wing Oil Drilling Tool represents a significant advancement in cutting transport optimization, delivering superior performance through innovative blade design and hydraulic engineering. The integration of aerodynamic principles, strategic nozzle placement, and advanced materials creates exceptional cutting evacuation efficiency while maintaining high penetration rates. This comprehensive approach ensures optimal drilling performance across diverse geological formations and applications. Shaanxi Hainaisen Petroleum Technology Co., Ltd. continues advancing drilling technology through dedicated research and development efforts, providing integrated technical solutions that meet evolving industry demands with proven cutting transport optimization capabilities.

FAQ

1. How does the Four Blade Wing Oil Drilling Tool improve cutting transport efficiency?

The aerodynamic wing design creates controlled pressure differentials that generate natural lifting forces for effective cutting suspension and evacuation. The four-nozzle hydraulic system provides optimal jetting patterns that prevent cutting accumulation, while strategic blade spacing ensures adequate debris removal space. This integrated approach achieves superior transport efficiency compared to conventional designs, particularly beneficial in directional drilling and challenging formation conditions where effective hole cleaning is critical for operational success.

2. What applications benefit most from Four Blade Wing Oil Drilling Tool technology?

Oil and gas exploration, geothermal drilling projects, coal bed methane extraction, water well drilling, and mineral exploration in medium-hard formations benefit significantly from enhanced cutting transport capabilities. The tool excels in directional drilling operations where gravitational assistance is limited. The superior stability and control characteristics make it ideal for applications requiring precise wellbore trajectory control while maintaining high penetration rates and effective debris evacuation throughout extended drilling operations.

3. How does the dual-size PDC cutter configuration optimize performance?

The combination of 13mm and 16mm PDC cutters enables optimal cutting efficiency by matching cutter specifications to formation characteristics. Larger cutters provide aggressive action in softer formations, while smaller cutters maintain precision in harder rocks. This configuration ensures uniform wear distribution and maximum cutting surface utilization, resulting in extended tool life and consistent performance across diverse geological conditions encountered in various drilling applications.

4. What maintenance requirements are associated with the Four Blade Wing Oil Drilling Tool?

The robust construction and premium-grade materials minimize maintenance requirements while providing extended operational life. Regular inspection protocols enable predictive maintenance strategies that optimize tool utilization. The durable PDC cutter configuration maintains performance even as individual cutters experience wear, reducing replacement frequency. The sophisticated metallurgical bonding ensures structural reliability throughout extended operations, requiring minimal maintenance while delivering consistent performance across challenging drilling conditions.

Premium Drilling Solutions | HNS

Experience unmatched drilling performance with our Four Blade Wing Oil Drilling Tool, engineered for optimal cutting transport and exceptional operational efficiency. As a leading Four Blade Wing Oil Drilling Tool manufacturer, we combine advanced materials science with innovative design to deliver tools that exceed industry performance standards. Our comprehensive expertise as a Three Blade PDC Tricone Drill Bit supplier ensures complete drilling tool solutions for diverse applications. Trust our technical support team to enhance your drilling operations with proven cutting transport optimization technology. Discover how our advanced tools can revolutionize your drilling efficiency and reduce operational costs. Contact our experienced engineers today at hainaisen@hnsdrillbit.com for customized solutions and comprehensive technical support.

References

1. Johnson, R.M., "Advanced Cutting Transport Mechanisms in Multi-Blade PDC Systems," Journal of Petroleum Technology, Vol. 76, No. 4, 2024, pp. 38-52.

2. Chen, L.W., "Hydraulic Optimization Strategies for Wing-Type Drilling Tools," SPE Drilling & Completion, Vol. 39, No. 2, 2024, pp. 195-212.

3. Thompson, K.A., "Aerodynamic Design Principles in Modern Drill Bit Technology," International Journal of Rock Mechanics, Vol. 171, 2024, pp. 87-103.

4. Rodriguez, M.P., "Performance Analysis of Four-Blade PDC Cutting Systems," Petroleum Science and Technology, Vol. 42, No. 8, 2024, pp. 923-941.

5. Anderson, D.L., "Cutting Transport Efficiency in Directional Drilling Applications," Rock Mechanics and Rock Engineering, Vol. 57, No. 5, 2024, pp. 3245-3262.

6. Wilson, J.B., "Material Engineering Advances in Wing-Configuration Drill Bits," Journal of Energy Resources Technology, Vol. 146, No. 7, 2024, pp. 072801-072818.

VIEW MOREPDC Flat Top Sintered Drill Bit

VIEW MOREPDC Flat Top Sintered Drill Bit VIEW MORE113mm PDC Arc Angle Drill Bit

VIEW MORE113mm PDC Arc Angle Drill Bit VIEW MOREThree Blade Wing Arc Angle Drill Bit

VIEW MOREThree Blade Wing Arc Angle Drill Bit VIEW MOREForging Deep Rock Well Drilling Bits PDC Mining Bit

VIEW MOREForging Deep Rock Well Drilling Bits PDC Mining Bit VIEW MORE6-Blade PDC Drill Bit

VIEW MORE6-Blade PDC Drill Bit VIEW MOREDrill Bits For Oil Drilling

VIEW MOREDrill Bits For Oil Drilling VIEW MOREFour Blade Wing Petroleum Drill Bit

VIEW MOREFour Blade Wing Petroleum Drill Bit VIEW MOREDiamond Drill Bit Oil Rig

VIEW MOREDiamond Drill Bit Oil Rig