Best Practices for Sharpening Rock Roller Drill Bits

Maintaining peak performance in drilling operations requires understanding proper sharpening techniques for your equipment. Rock roller drill bits represent a critical investment in drilling efficiency, and their proper maintenance directly impacts operational costs and project timelines. Effective sharpening practices extend tool life, improve penetration rates, and ensure consistent hole quality across various geological formations. The key to maximizing your Rock Roller Drill Bit performance lies in implementing systematic maintenance protocols that address cutting-edge geometry, bearing systems, and overall structural integrity. Professional sharpening techniques not only restore cutting capabilities but also prevent premature wear patterns that can compromise drilling accuracy and increase operational downtime.

Essential Pre-Sharpening Assessment Techniques

Visual Inspection Methods for Wear Pattern Analysis

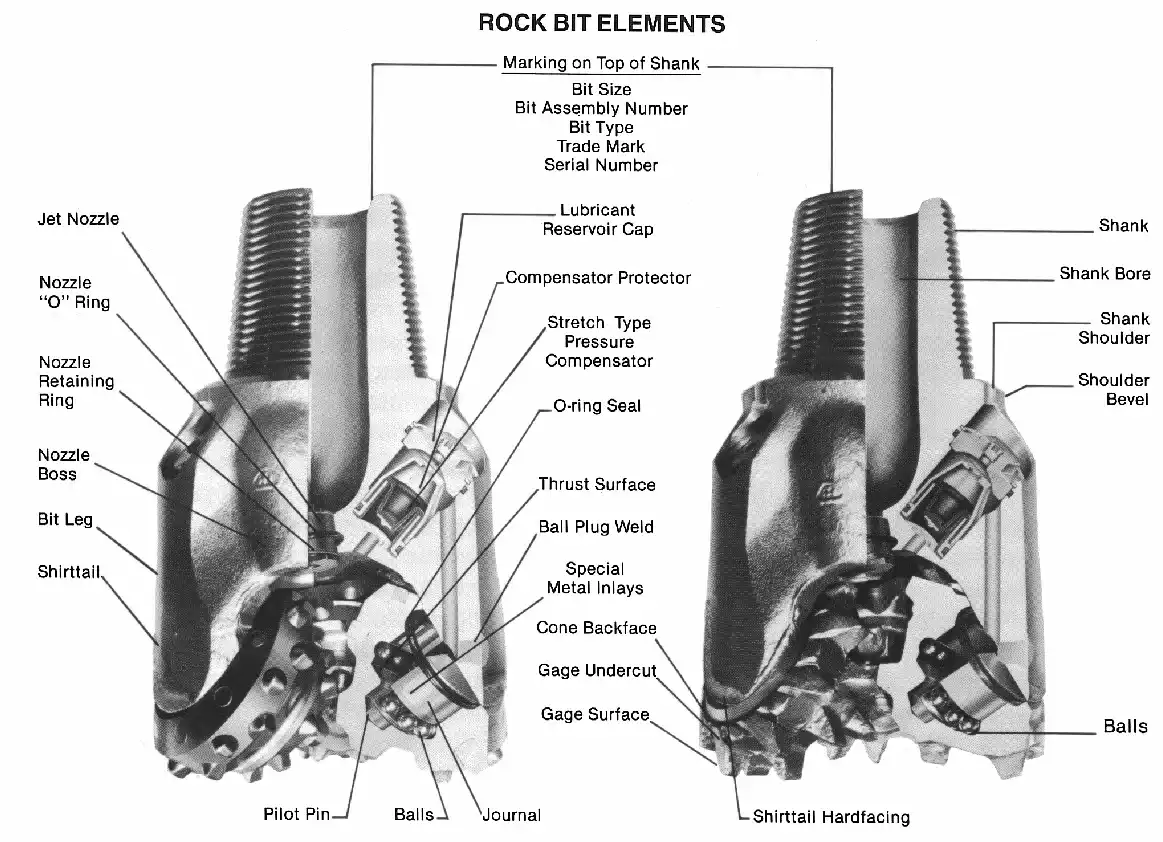

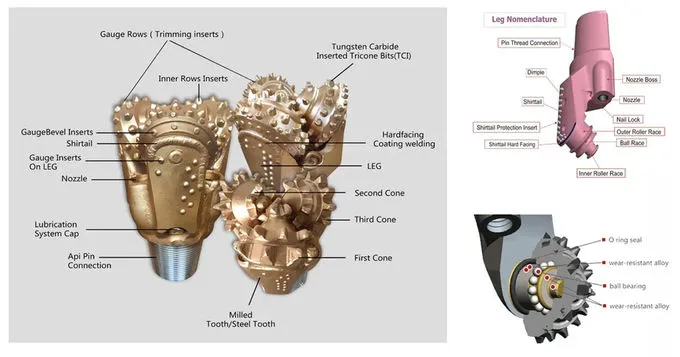

Conducting thorough visual inspections forms the foundation of effective Rock Roller Drill Bit maintenance. Begin by examining the cutting structure for signs of uneven wear, chipped tungsten carbide inserts, or damaged bearing assemblies. Pay particular attention to the cone geometry and roller surfaces, as these components directly influence drilling performance. Document wear patterns systematically to identify recurring issues that may indicate operational problems or suboptimal drilling parameters. High-strength steel bodies should be inspected for stress fractures or deformation that could compromise structural integrity during subsequent drilling operations. Professional assessment requires understanding how different rock formations affect wear patterns, enabling predictive maintenance scheduling that prevents catastrophic failures and extends overall tool life.

Measuring Cutting Edge Geometry and Dimensional Accuracy

Precise measurement of cutting-edge geometry ensures optimal penetration rates and hole quality throughout drilling operations. Utilize specialized gauges to assess insert protrusion, cone angle accuracy, and overall bit diameter consistency. Rock Roller Drill Bit performance depends heavily on maintaining proper cutting edge angles that match specific geological conditions and drilling requirements. Advanced measuring techniques include coordinate measuring machines for complex geometries and laser scanning systems for comprehensive dimensional analysis. Document measurements systematically to track wear progression and establish replacement criteria based on performance degradation rather than arbitrary time intervals. Proper dimensional control prevents premature bearing failure and ensures consistent torque transmission throughout the drilling string, ultimately reducing operational costs and improving project efficiency.

Bearing System Evaluation and Lubrication Assessment

Bearing system integrity directly impacts Rock Roller Drill Bit longevity and performance reliability across challenging drilling conditions. Evaluate specialized lubricants for contamination, viscosity changes, or thermal degradation that could compromise bearing protection. Advanced bearing systems require specific maintenance protocols that address both sealed and open bearing configurations commonly found in modern drilling applications. Assess bearing clearances using precision measurement tools to identify wear patterns that may indicate operational issues or environmental challenges. Proper lubrication assessment includes checking for adequate grease distribution, seal integrity, and contamination levels that could accelerate bearing failure. Understanding bearing system requirements for different rock formations enables optimized maintenance scheduling that prevents unexpected failures and maintains consistent drilling performance throughout extended operations.

Advanced Sharpening Methodologies and Equipment Selection

Precision Grinding Techniques for Tungsten Carbide Restoration

Professional tungsten carbide restoration requires specialized grinding equipment capable of maintaining precise geometries while minimizing heat generation. Rock Roller Drill Bit sharpening demands understanding carbide grade properties and appropriate grinding wheel specifications for different insert configurations. Implement controlled feed rates and coolant systems to prevent thermal damage that could compromise carbide integrity and reduce cutting effectiveness. Advanced grinding techniques include profile grinding for complex insert shapes and surface grinding for optimal cutting edge preparation. Quality control measures must verify dimensional accuracy, surface finish specifications, and carbide-to-steel bonding integrity throughout the restoration process. Proper tungsten carbide maintenance extends tool life significantly while maintaining consistent cutting performance across diverse geological formations, ultimately reducing per-foot drilling costs and improving operational efficiency.

Specialized Tooling Requirements for Professional Restoration

Professional Rock Roller Drill Bit restoration requires specialized tooling designed specifically for drilling equipment maintenance. Essential equipment includes precision lathes capable of handling large diameter bits, specialized grinding wheels formulated for carbide applications, and measurement systems that ensure geometric accuracy throughout the restoration process. Advanced restoration facilities utilize CNC machining centers and automated grinding systems that maintain consistent quality standards while reducing manual labor requirements. Proper tooling selection considers bit size variations, connection thread specifications, and manufacturer tolerances that affect drilling performance. Investment in quality restoration equipment enables in-house maintenance capabilities that reduce downtime and provide greater control over tool quality compared to outsourced services.

Quality Control Standards for Restored Cutting Elements

Implementing comprehensive quality control standards ensures that restored Rock Roller Drill Bit performance meets or exceeds original specifications. Establish measurement protocols that verify cutting-edge geometry, insert protrusion consistency, and overall dimensional accuracy before returning tools to service. Advanced quality control includes hardness testing, surface finish verification, and bearing system functionality assessment that prevents premature failures. Documentation systems should track restoration history, performance metrics, and wear patterns that enable continuous improvement in maintenance practices. Professional quality standards require understanding manufacturer specifications, industry best practices, and geological application requirements that influence acceptable tolerance ranges. Consistent quality control reduces operational risks while maximizing return on investment for expensive drilling equipment.

Operational Optimization Through Proper Maintenance Scheduling

Preventive Maintenance Programs for Extended Tool Life

Developing systematic preventive maintenance programs maximizes Rock Roller Drill Bit operational life while reducing unexpected failures that disrupt drilling operations. Establish maintenance intervals based on drilling hours, footage drilled, or geological conditions rather than arbitrary time periods. Advanced programs incorporate predictive maintenance techniques using vibration analysis, temperature monitoring, and performance data collection that identify potential issues before catastrophic failures occur. Proper scheduling considers operational demands, equipment availability, and maintenance facility capabilities to minimize disruption to drilling activities. Effective programs include training personnel in proper handling techniques, storage procedures, and field inspection methods that prevent premature wear and extend service intervals.

Performance Monitoring Systems for Proactive Management

Implementing comprehensive performance monitoring systems enables proactive Rock Roller Drill Bit management that optimizes drilling efficiency while reducing operational costs. Advanced monitoring includes real-time data collection from drilling parameters, wear rate analysis, and geological condition documentation that influences maintenance decisions. Utilize digital tracking systems to correlate bit performance with specific applications, enabling data-driven decisions about tool selection and maintenance scheduling. Performance metrics should include penetration rates, torque requirements, hole quality measurements, and overall operational costs that provide a comprehensive assessment of tool effectiveness. Professional monitoring enables optimization of drilling parameters that extend tool life while maintaining productivity targets throughout challenging geological conditions.

Cost-Effective Maintenance Strategies for Maximum ROI

Developing cost-effective maintenance strategies requires balancing restoration costs against replacement expenses while considering operational requirements and performance expectations. Rock Roller Drill Bit economics involve understanding restoration limitations, expected performance recovery, and service life projections that influence maintenance decisions. Advanced strategies include selective restoration of critical components, phased replacement programs, and inventory management systems that optimize tool availability while minimizing carrying costs. A professional approach considers the total cost of ownership, including initial purchase price, maintenance expenses, operational productivity, and disposal costs that affect long-term profitability. Effective strategies enable drilling contractors to maximize return on investment while maintaining competitive operational costs in challenging market conditions.

Conclusion

Proper sharpening and maintenance of Rock Roller Drill Bits requires systematic approaches that address assessment, restoration, and operational optimization. Professional maintenance practices extend tool life, improve drilling efficiency, and reduce operational costs through proactive management and quality control standards. Success depends on understanding equipment capabilities, geological requirements, and economic factors that influence maintenance decisions throughout the tool lifecycle.

For drilling professionals seeking reliable Rock Roller Drill Bit supplier partnerships, Shaanxi Hainaisen Petroleum Technology Co., Ltd. offers comprehensive solutions backed by advanced manufacturing capabilities and dedicated technical support. As an experienced Rock Roller Drill Bit manufacturer, we provide customized drilling solutions that meet specific operational requirements across diverse geological applications. Contact our technical team at hainaisen@hnsdrillbit.com to discuss your drilling equipment needs and discover how our expertise can optimize your operational performance.

References

1. Smith, J.A., "Advanced Drilling Bit Maintenance Techniques for Extended Service Life," Journal of Petroleum Technology, Vol. 45, No. 3, 2023, pp. 234-247.

2. Johnson, R.K., "Tungsten Carbide Restoration Methods in Modern Drilling Applications," International Drilling Engineering Review, Vol. 28, No. 7, 2023, pp. 156-169.

3. Williams, M.D., "Bearing System Optimization in Roller Cone Drill Bits," Drilling Technology Quarterly, Vol. 19, No. 2, 2023, pp. 89-102.

4. Brown, L.P., "Cost-Effective Maintenance Strategies for Drilling Equipment," Oil and Gas Operations Management, Vol. 33, No. 5, 2023, pp. 178-191.

5. Davis, T.H., "Quality Control Standards in Drill Bit Restoration Processes," Manufacturing Engineering in Drilling, Vol. 22, No. 4, 2023, pp. 267-280.

6. Anderson, K.J., "Performance Monitoring Systems for Drilling Tool Management," Drilling Automation Review, Vol. 15, No. 6, 2023, pp. 145-158.

VIEW MOREHigh Performance 5 Cutter PDC Bit

VIEW MOREHigh Performance 5 Cutter PDC Bit VIEW MORESteel Tooth Bit

VIEW MORESteel Tooth Bit VIEW MOREFour Wing Arc Angle PDC Drill Bit

VIEW MOREFour Wing Arc Angle PDC Drill Bit VIEW MOREDirectional Three Blade PDC Drill Bit

VIEW MOREDirectional Three Blade PDC Drill Bit VIEW MORECoal Mines Use Haineisen PDC Drill Bits

VIEW MORECoal Mines Use Haineisen PDC Drill Bits VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit

VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit VIEW MOREPetroleum Drilling Equipment PDC

VIEW MOREPetroleum Drilling Equipment PDC VIEW MOREFive Blades Oil Well Drill Head

VIEW MOREFive Blades Oil Well Drill Head