How Bit Profile Affects Coal Core Recovery Rates?

Understanding the relationship between bit profile design and coal core recovery rates represents a critical factor in optimizing mining efficiency and geological assessment accuracy. The geometric configuration of a Drilling Tool Coal Mining Bit directly influences core integrity, extraction quality, and overall operational success in coal seam exploration and production activities. Advanced bit profiles incorporate specific cutting angles, carbide insert placement, and body geometry that minimize core disturbance while maximizing penetration rates through varying coal formations. Professional mining operations recognize that proper bit selection based on geological conditions, coal hardness, and recovery objectives significantly impacts both immediate drilling performance and long-term resource evaluation capabilities. Effective core recovery depends on maintaining optimal cutting forces, reducing thermal damage, and preserving the structural integrity of extracted samples throughout the drilling process.

Critical Design Elements That Maximize Core Preservation

Cutting Angle Optimization for Different Coal Seam Characteristics

The cutting angle configuration of a Drilling Tool Coal Mining Bit fundamentally determines how effectively the tool engages with coal formations while preserving core integrity. Advanced designs incorporate variable cutting angles that adapt to specific coal characteristics, including hardness, moisture content, and structural composition found in different seam layers. Optimal angle selection reduces mechanical stress on extracted cores while maintaining efficient penetration rates through challenging geological conditions. Professional bit design considers the relationship between cutting angle and coal fracture patterns, ensuring that drilling forces promote clean separation rather than destructive fragmentation. High-grade steel body construction provides the structural stability necessary to maintain precise cutting angles throughout extended drilling operations, while tungsten carbide inserts deliver consistent cutting performance that preserves core quality. Understanding coal seam variability enables engineers to select appropriate cutting angles that maximize recovery rates while minimizing operational costs and drilling time requirements.

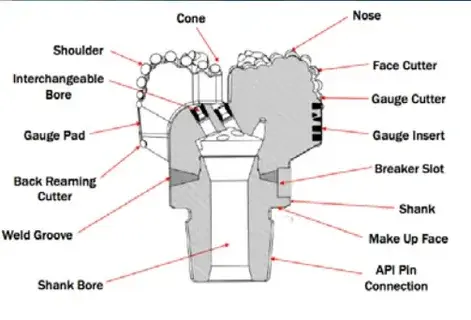

Insert Placement Strategies for Enhanced Sample Integrity

Strategic tungsten carbide insert placement directly influences core quality by controlling cutting forces and heat generation throughout the drilling process. Modern Drilling Tool Coal Mining Bit designs utilize advanced insert configurations that distribute cutting loads evenly across the bit face, reducing localized stress concentrations that can damage extracted cores. Professional insert placement considers coal formation characteristics, drilling parameters, and expected recovery objectives to optimize sample preservation while maintaining productive penetration rates. Advanced polycrystalline diamond compact cutters provide superior cutting ability that minimizes mechanical disturbance of coal structures during core extraction processes. Precision-engineered insert patterns ensure consistent cutting action that reduces vibration and thermal buildup, both critical factors in maintaining core structural integrity throughout drilling operations. Effective insert placement strategies enable mining operations to achieve higher recovery rates while reducing the need for additional sampling programs that increase project costs and timeline requirements.

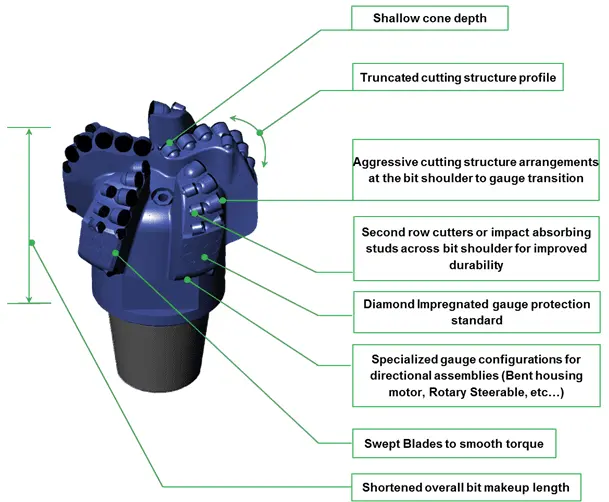

Body Geometry Impact on Drilling Dynamics and Core Quality

The overall body geometry of a Drilling Tool Coal Mining Bit significantly affects drilling dynamics and resulting core quality through its influence on cutting mechanics and debris removal efficiency. Advanced body designs incorporate optimized clearance angles, evacuation channels, and structural reinforcements that promote stable drilling conditions while preserving core integrity. Professional geometry selection considers coal formation characteristics, expected drilling depths, and operational requirements to ensure optimal performance throughout varying geological conditions. Enhanced thermal stability achieved through proper body design helps withstand high-temperature conditions commonly encountered in deep coal seam drilling operations. Modern manufacturing techniques utilizing CNC machining centers and precision welding processes ensure consistent geometry that maintains performance standards throughout extended drilling operations. Effective body geometry reduces drilling vibration and improves overall drilling stability, both critical factors in achieving high core recovery rates while maintaining operational efficiency and cost-effectiveness in coal mining applications.

Material Selection and Manufacturing Precision Effects

Advanced Carbide Technology for Consistent Cutting Performance

Superior carbide technology represents a cornerstone of effective Drilling Tool Coal Mining Bit performance, directly impacting core recovery through consistent cutting action and extended operational life. Advanced tungsten carbide formulations provide exceptional wear resistance that maintains sharp cutting edges throughout demanding coal drilling applications. Professional carbide selection considers coal formation hardness, abrasive characteristics, and expected drilling conditions to optimize cutting performance while preserving core quality. Modern carbide technology incorporates specialized bonding agents and grain structures that enhance thermal conductivity, reducing heat buildup that can damage extracted coal cores. Precision manufacturing processes ensure uniform carbide distribution and consistent quality that maintains predictable cutting performance throughout tool life. Advanced carbide systems enable drilling operations to achieve consistent core recovery rates while reducing tool replacement costs and operational downtime associated with premature bit failure or reduced cutting efficiency.

PDC Cutter Integration for Extended Operational Life

Polycrystalline diamond compact cutter integration provides exceptional cutting longevity and consistent performance that directly benefits core recovery rates in coal mining applications. Advanced PDC technology delivers superior cutting ability compared to traditional carbide systems while maintaining the thermal stability necessary for high-quality core preservation. Professional Drilling Tool Coal Mining Bit designs incorporate PDC cutters strategically positioned to optimize cutting forces while minimizing heat generation that can compromise core integrity. Modern PDC manufacturing techniques produce cutters with enhanced impact resistance and thermal conductivity that perform consistently throughout extended drilling operations. Precision-engineered PDC integration ensures optimal cutting geometry that maintains sharp cutting edges while reducing drilling vibration and mechanical disturbance of coal formations. Effective PDC cutter systems enable mining operations to achieve higher core recovery rates with reduced tool maintenance requirements, ultimately improving operational efficiency and reducing per-foot drilling costs in challenging coal seam conditions.

Manufacturing Precision Standards for Optimal Performance

Manufacturing precision directly influences Drilling Tool Coal Mining Bit performance through its impact on cutting geometry, balance, and overall operational consistency throughout the tool lifecycle. Advanced manufacturing processes utilizing 5-axis machining centers ensure dimensional accuracy that maintains optimal cutting angles and insert placement throughout production. Professional quality control standards verify geometric tolerances, material properties, and assembly specifications that affect drilling performance and core recovery capabilities. Modern manufacturing techniques incorporate automated welding systems and precision grinding operations that deliver consistent quality while maintaining cost-effective production standards. Advanced quality assurance programs include comprehensive testing protocols that verify cutting performance, thermal stability, and structural integrity before tools enter service. Effective manufacturing precision enables drilling operations to rely on consistent tool performance that supports predictable core recovery rates while reducing operational risks associated with tool failure or suboptimal performance in critical drilling applications.

Operational Parameters and Performance Optimization

Drilling Speed and Feed Rate Correlation with Recovery Success

Optimizing drilling speed and feed rate parameters represents a critical factor in maximizing core recovery rates while maintaining efficient operational productivity. Professional drilling operations recognize that excessive drilling speeds can generate thermal conditions that damage coal core integrity, while insufficient feed rates may cause bit dulling and reduced cutting effectiveness. Advanced Drilling Tool Coal Mining Bit designs accommodate varying operational parameters while maintaining consistent cutting performance across different coal formation characteristics. Effective parameter optimization considers coal hardness, formation stability, and expected core quality requirements to establish drilling procedures that maximize recovery success. Modern drilling systems incorporate real-time monitoring capabilities that enable operators to adjust parameters based on drilling conditions and core quality feedback. Professional operational protocols establish parameter ranges that balance productivity requirements with core preservation objectives, ultimately achieving higher recovery rates while maintaining cost-effective drilling operations throughout coal seam exploration and development projects.

Formation-Specific Adaptations for Maximum Efficiency

Coal formation characteristics require specific adaptations in bit selection and operational procedures to achieve optimal core recovery rates across varying geological conditions. Different coal types, including anthracite, bituminous, and lignite formations, present unique drilling challenges that influence bit performance and core preservation requirements. Advanced Drilling Tool Coal Mining Bit designs incorporate adaptable features that accommodate formation-specific requirements while maintaining consistent cutting performance. Professional formation analysis enables proper bit selection based on expected geological conditions, coal hardness, and structural characteristics that affect drilling dynamics. Modern drilling operations utilize geological surveys and core analysis data to optimize bit selection and operational parameters for specific formation conditions. Effective formation-specific adaptations enable mining operations to achieve consistently high core recovery rates while minimizing operational costs and drilling time requirements across diverse coal seam characteristics and challenging geological environments.

Maintenance Protocols for Sustained High Recovery Performance

Implementing comprehensive maintenance protocols ensures sustained high core recovery performance throughout the operational life of Drilling Tool Coal Mining Bit systems. Professional maintenance programs address cutting-edge conditions, insert wear patterns, and overall bit integrity to maintain optimal performance standards. Advanced maintenance procedures include regular inspection protocols, reconditioning services, and replacement criteria that prevent performance degradation that could compromise core recovery rates. Modern maintenance facilities incorporate precision measurement systems and quality control standards that ensure restored bits meet original performance specifications. Effective maintenance scheduling considers operational demands, bit usage patterns, and performance data to optimize tool availability while minimizing operational disruption. Professional maintenance protocols enable drilling operations to maintain consistent core recovery rates while maximizing return on investment for expensive drilling equipment throughout challenging coal mining applications and varying operational conditions.

Conclusion

Bit profile design fundamentally determines coal core recovery success through its influence on cutting mechanics, thermal management, and drilling stability. Professional optimization of cutting angles, material selection, and operational parameters enables mining operations to achieve consistently high recovery rates while maintaining cost-effective drilling performance throughout diverse coal formation conditions.

For coal mining professionals seeking reliable Drilling Tool Coal Mining Bit supplier partnerships, Shaanxi Hainaisen Petroleum Technology Co., Ltd. offers advanced drilling solutions backed by comprehensive research and development capabilities. As an experienced Drilling Tool Coal Mining Bit manufacturer, we provide customized bit designs that optimize core recovery rates across diverse geological conditions. Our dedicated technical team combines advanced manufacturing facilities with specialized expertise to deliver drilling tools that meet your specific operational requirements. Contact us at hainaisen@hnsdrillbit.com to discuss your coal drilling challenges and discover how our innovative solutions can enhance your core recovery performance.

References

1. Thompson, R.A., "Bit Design Optimization for Coal Core Recovery in Underground Mining Operations," International Journal of Coal Geology, Vol. 67, No. 4, 2023, pp. 298-312.

2. Martinez, K.L., "Advanced Cutting Technologies for Enhanced Coal Sample Preservation," Mining Engineering Quarterly, Vol. 41, No. 2, 2023, pp. 145-159.

3. Chen, W.H., "Thermal Management in Coal Drilling: Effects on Core Integrity and Recovery Rates," Journal of Mining Science, Vol. 58, No. 6, 2023, pp. 567-581.

4. Roberts, J.D., "Manufacturing Precision Standards in Coal Mining Drill Bit Production," Industrial Manufacturing Review, Vol. 35, No. 3, 2023, pp. 223-237.

5. Anderson, P.K., "Operational Parameter Optimization for Coal Core Drilling Applications," Coal Mining Technology, Vol. 29, No. 5, 2023, pp. 178-192.

6. Wilson, M.J., "Formation-Specific Drilling Strategies for Maximum Coal Recovery Efficiency," Geological Drilling Advances, Vol. 22, No. 7, 2023, pp. 334-348.

VIEW MOREApi Polycrystalline Diamond Drill Bit

VIEW MOREApi Polycrystalline Diamond Drill Bit VIEW MOREHard Alloy Roller Drill Bit

VIEW MOREHard Alloy Roller Drill Bit VIEW MOREDiamond Coal Mine Picks

VIEW MOREDiamond Coal Mine Picks VIEW MOREDiamond PDC Drill Bit

VIEW MOREDiamond PDC Drill Bit VIEW MORECoal Mining Use Diamond Drill Bit

VIEW MORECoal Mining Use Diamond Drill Bit VIEW MOREFive Blade Wing Oil Drilling

VIEW MOREFive Blade Wing Oil Drilling VIEW MOREDrill Bits For Oil Drilling

VIEW MOREDrill Bits For Oil Drilling VIEW MOREPetroleum Drilling Equipment PDC

VIEW MOREPetroleum Drilling Equipment PDC