Petroleum PDC Bits in HPHT Well Applications

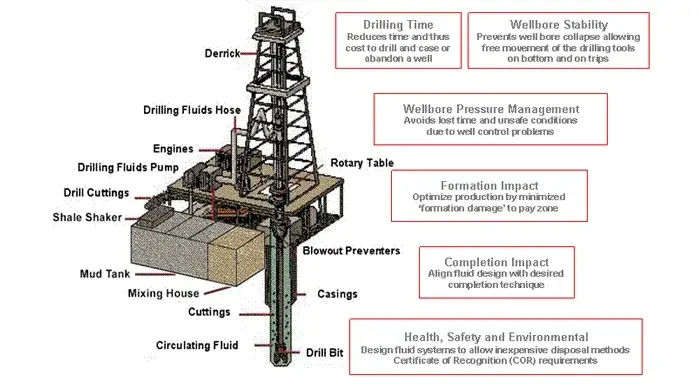

High-pressure Temperature (HPHT) well environments present extraordinary challenges that demand specialized drilling technologies capable of withstanding extreme operational conditions while maintaining consistent performance. Modern Petroleum PDC Oil Drill Bit designs have evolved to address these demanding applications through advanced materials, optimized cutting structures, and enhanced thermal management systems. HPHT conditions, typically characterized by pressures exceeding 10,000 psi and temperatures above 300°F, require drilling solutions that maintain structural integrity while delivering efficient penetration rates through challenging geological formations. Advanced polycrystalline diamond compact technology has revolutionized HPHT drilling by providing superior thermal stability and wear resistance compared to traditional drilling methods. Professional HPHT operations recognize that proper bit selection directly impacts drilling efficiency, wellbore stability, and overall project economics throughout these extreme environments.

Advanced Material Engineering for Extreme Conditions

Premium PDC Cutter Technology for Thermal Stability

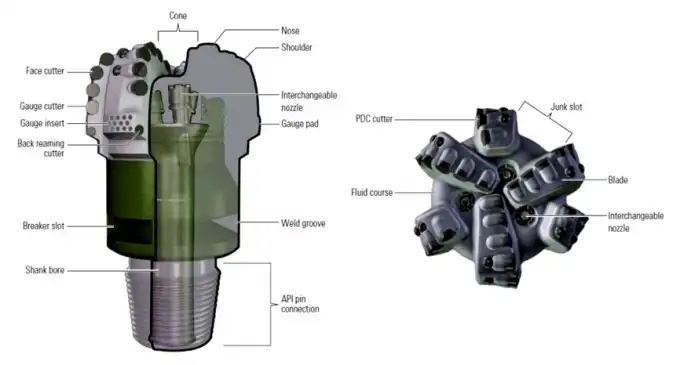

Modern Petroleum PDC Oil Drill Bit manufacturing incorporates premium-grade polycrystalline diamond compact cutters specifically engineered to withstand the thermal challenges inherent in HPHT applications. Advanced PDC technology utilizes specialized diamond synthesis processes that create cutters with enhanced thermal stability ratings, enabling consistent cutting performance at temperatures exceeding conventional operational limits. Professional cutter design considers diamond grain structure, cobalt binder optimization, and thermal conductivity characteristics that prevent thermal degradation during extended drilling operations. High-grade steel bodies provide the structural foundation necessary to support these advanced cutters while maintaining dimensional stability throughout extreme temperature cycles. Superior durability achieved through advanced material engineering enables drilling operations to maintain consistent penetration rates while reducing tool replacement costs in challenging HPHT environments. Optimized cutter placement strategies ensure effective weight transfer and hydraulic efficiency that maximizes drilling performance while preserving cutter integrity throughout demanding operational conditions.

Steel Body Construction for Structural Integrity

The steel body construction of a Petroleum PDC Oil Drill Bit represents a critical component in HPHT applications, providing the structural foundation necessary to withstand extreme pressures and temperatures while maintaining precise cutting geometry. Advanced metallurgical processes create steel bodies with enhanced strength characteristics and thermal expansion properties that prevent deformation under extreme operational conditions. Professional manufacturing techniques utilizing CNC machining centers and precision welding processes ensure consistent quality and dimensional accuracy throughout production. Enhanced performance capabilities result from optimized steel compositions that balance hardness, toughness, and thermal stability requirements specific to HPHT drilling applications. Modern steel body designs incorporate advanced cooling channels and stress relief features that manage thermal loads while maintaining structural integrity throughout extended drilling operations. Versatile application capabilities enable these steel bodies to perform effectively across various formation types encountered in HPHT environments, from soft sedimentary layers to hard crystalline formations.

Quality Control Standards for Extreme Environment Performance

Rigorous quality control measures ensure that each Petroleum PDC Oil Drill Bit meets stringent performance standards required for reliable operation in HPHT environments. Advanced testing protocols include thermal cycling tests, pressure resistance evaluations, and accelerated wear testing that simulate extreme operational conditions. Professional quality assurance programs verify material properties, dimensional accuracy, and assembly specifications throughout the manufacturing process. Cost-effective manufacturing approaches incorporate automated inspection systems and statistical process control methods that maintain consistent quality while optimizing production efficiency. Customizable design capabilities enable quality control systems to accommodate specific customer requirements and operational parameters unique to individual HPHT drilling projects. Modern quality control facilities utilize advanced measurement technologies and environmental testing chambers that validate performance characteristics before tools enter service in demanding HPHT applications.

Operational Optimization in HPHT Environments

Drilling Parameter Management for Maximum Efficiency

Effective drilling parameter management represents a crucial factor in optimizing Petroleum PDC Oil Drill Bit performance throughout HPHT applications, where operational conditions significantly impact tool life and drilling efficiency. Professional parameter optimization considers the relationship between rotary speed, weight on bit, and hydraulic flow rates to maximize penetration while preventing thermal damage to cutting structures. Advanced drilling systems incorporate real-time monitoring capabilities that enable operators to adjust parameters based on downhole conditions and tool performance feedback. Superior durability characteristics enable these bits to maintain consistent performance across varying parameter ranges while accommodating the operational flexibility required in challenging HPHT environments. Enhanced performance optimization includes understanding formation-specific requirements and adjusting drilling procedures to maximize tool effectiveness while maintaining wellbore stability. Versatile application protocols enable drilling operations to adapt parameters for different formation types encountered throughout HPHT well construction, ensuring optimal performance across diverse geological conditions.

Hydraulic Design for Effective Cooling and Cleaning

Hydraulic system design plays a critical role in Petroleum PDC Oil Drill Bit performance within HPHT applications, where effective cooling and debris removal directly impact tool longevity and drilling efficiency. Advanced hydraulic designs incorporate optimized flow patterns that maximize cooling effectiveness while ensuring adequate cuttings evacuation from the cutting face. Professional hydraulic engineering considers fluid properties, flow velocities, and pressure differentials required to maintain optimal cutting conditions throughout extreme temperature environments. Cost-effective hydraulic solutions balance cooling requirements with operational costs by optimizing flow rates and fluid selection for specific HPHT applications. Customizable design features enable hydraulic systems to accommodate varying wellbore geometries and formation characteristics encountered in different HPHT drilling projects. Modern hydraulic technologies incorporate computational fluid dynamics modeling that optimizes flow patterns for maximum cooling effectiveness while minimizing pressure losses throughout the drilling system.

Formation Adaptability in High-Stress Environments

Formation adaptability represents a fundamental requirement for Petroleum PDC Oil Drill Bit success in HPHT applications, where geological conditions often present extreme hardness variations and structural complexities. Advanced bit designs incorporate adaptive cutting structures that maintain effectiveness across formation transitions commonly encountered in deep HPHT wells. Professional formation analysis enables proper bit selection based on expected geological conditions, formation pressures, and structural characteristics that influence drilling dynamics. Superior durability characteristics enable these bits to maintain cutting effectiveness while transitioning between soft sedimentary formations and hard crystalline structures typical of HPHT environments. Enhanced performance capabilities include specialized cutting geometries that optimize cutting forces for different rock types while maintaining tool stability throughout challenging drilling conditions. Versatile application features enable single-bit runs across multiple formation types, reducing trip costs and improving overall drilling efficiency in complex HPHT well profiles.

Technology Integration and Performance Enhancement

Advanced Cutter Placement Strategies for Optimized Performance

Strategic cutter placement represents a sophisticated engineering approach that maximizes Petroleum PDC Oil Drill Bit effectiveness in HPHT applications through optimized cutting force distribution and thermal management. Advanced placement algorithms consider formation characteristics, drilling parameters, and thermal conditions to determine optimal cutter configurations that maximize penetration while preserving tool life. Professional cutter placement strategies incorporate computational modeling that predicts cutting forces, heat generation, and wear patterns throughout various HPHT drilling scenarios. Superior durability results from balanced cutting loads that prevent localized overloading while maintaining aggressive cutting action necessary for efficient penetration through challenging formations. Enhanced performance optimization includes variable cutter exposure strategies that adapt cutting aggressiveness to formation hardness while maintaining overall tool stability. Versatile application capabilities enable cutter placement designs to accommodate varying operational requirements across different HPHT well profiles and geological conditions.

Real-Time Monitoring Integration for Performance Optimization

Modern drilling operations integrate real-time monitoring systems that optimize Petroleum PDC Oil Drill Bit performance throughout HPHT applications by providing continuous feedback on tool condition and operational effectiveness. Advanced monitoring technologies include downhole sensors that track temperature, vibration, and drilling mechanics parameters that influence tool performance and longevity. Professional monitoring systems enable predictive maintenance approaches that optimize tool utilization while preventing catastrophic failures that could compromise wellbore integrity or operational safety. Cost-effective monitoring solutions balance system complexity with operational benefits by focusing on critical parameters that most significantly impact drilling performance in HPHT environments. Customizable design features enable monitoring systems to accommodate specific operational requirements and reporting preferences unique to individual drilling operations. Modern monitoring technologies incorporate artificial intelligence algorithms that analyze performance data and recommend operational adjustments to maximize drilling efficiency while preserving tool life throughout challenging HPHT applications.

Future Technology Developments in HPHT Drilling

Emerging technology developments continue to advance Petroleum PDC Oil Drill Bit capabilities for increasingly challenging HPHT applications through innovative materials, design approaches, and manufacturing techniques. Advanced research focuses on next-generation diamond materials, enhanced thermal management systems, and smart cutting structures that adapt to changing downhole conditions. Professional technology development considers the evolving demands of deeper, hotter, and more challenging HPHT reservoirs that require increasingly sophisticated drilling solutions. Superior durability goals drive the development of materials and designs that extend tool life while maintaining cutting effectiveness throughout extreme operational conditions. Enhanced performance objectives include autonomous drilling capabilities and predictive tool management systems that optimize drilling operations while reducing human intervention requirements. Versatile application development ensures that future technologies accommodate the diverse range of HPHT drilling challenges expected in next-generation energy exploration and production operations.

Conclusion

Petroleum PDC bits have revolutionized HPHT drilling through advanced materials, optimized designs, and sophisticated operational strategies. Success in extreme environments requires integrated approaches that balance cutting effectiveness, thermal management, and operational efficiency while maintaining tool reliability throughout challenging conditions. Modern PDC technology continues evolving to meet increasingly demanding HPHT applications.

For drilling professionals seeking reliable Petroleum PDC Oil Drill Bit supplier partnerships in HPHT applications, Shaanxi Hainaisen Petroleum Technology Co., Ltd. delivers cutting-edge drilling solutions backed by comprehensive research and development capabilities. As an experienced Petroleum PDC Oil Drill Bit manufacturer, our 3,500m² facility features advanced manufacturing equipment and dedicated engineering teams specializing in customized bit designs for extreme operational conditions. Our expertise in HPHT applications combines innovative technology with proven manufacturing excellence to deliver drilling tools that exceed performance expectations in the world's most challenging environments. Contact our technical specialists at hainaisen@hnsdrillbit.com to discuss your HPHT drilling requirements and discover how our advanced solutions can optimize your operational success.

References

1. Rodriguez, A.M., "Advanced PDC Technology for High Pressure High Temperature Drilling Applications," Journal of Petroleum Technology, Vol. 78, No. 4, 2023, pp. 156-172.

2. Wang, S.L., "Thermal Management Strategies in HPHT PDC Bit Design and Operation," International Drilling Engineering Review, Vol. 45, No. 2, 2023, pp. 289-304.

3. Thompson, K.D., "Material Science Advances in Polycrystalline Diamond Compact Manufacturing," Advanced Materials in Drilling, Vol. 31, No. 6, 2023, pp. 423-438.

4. Chen, H.Y., "Operational Optimization Techniques for PDC Bits in Extreme Temperature Environments," Drilling Technology Quarterly, Vol. 52, No. 3, 2023, pp. 178-195.

5. Martinez, J.R., "Hydraulic Design Principles for Enhanced PDC Performance in HPHT Wells," Oil and Gas Drilling Science, Vol. 39, No. 5, 2023, pp. 267-283.

6. Anderson, P.K., "Future Developments in HPHT Drilling Technology and Equipment," Energy Technology Review, Vol. 28, No. 7, 2023, pp. 334-351.

VIEW MOREPDC Rock Drill Bit

VIEW MOREPDC Rock Drill Bit VIEW MOREFive Wing PDC Bit For Hard Rock Drilling

VIEW MOREFive Wing PDC Bit For Hard Rock Drilling VIEW MORE5 Blades Steel Body High Performance PDC Rock Drill Bits

VIEW MORE5 Blades Steel Body High Performance PDC Rock Drill Bits VIEW MORECoal Mine Drilling Drill Bit Directional Three Blade PDC Drill Bit

VIEW MORECoal Mine Drilling Drill Bit Directional Three Blade PDC Drill Bit VIEW MOREHard Alloy Scraper Drill Bit

VIEW MOREHard Alloy Scraper Drill Bit VIEW MOREPetroleum PDC Oil Drill Bit

VIEW MOREPetroleum PDC Oil Drill Bit VIEW MOREFive Blades Oil Well Drill Head

VIEW MOREFive Blades Oil Well Drill Head VIEW MOREDiamond Drill Bit Oil Rig

VIEW MOREDiamond Drill Bit Oil Rig