PDC Rock Drill Bit Material Properties and Wear Resistance

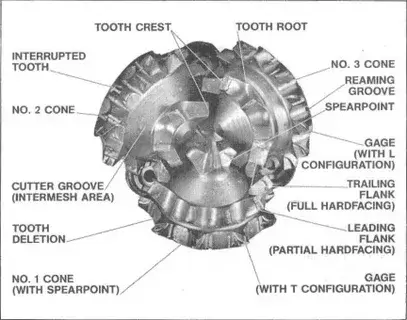

The effectiveness of drilling operations across various industries fundamentally depends on the material properties and wear resistance characteristics of cutting tools. PDC Rock Drill Bit technology represents a revolutionary advancement in drilling efficiency, combining polycrystalline diamond compact cutters with sophisticated engineering design. These advanced drilling tools have transformed modern drilling practices through their exceptional durability, superior cutting performance, and remarkable longevity under extreme operational conditions. Understanding the intricate relationship between material composition, structural design, and wear resistance mechanisms is essential for optimizing drilling performance in challenging geological formations. The comprehensive analysis of these properties enables engineers and drilling professionals to make informed decisions regarding tool selection and operational parameters.

Diamond Cutter Technology and Material Composition

Polycrystalline Diamond Compact Structure

The foundation of PDC Rock Drill Bit performance lies in the sophisticated structure of polycrystalline diamond compact cutters. These cutters consist of multiple diamond crystals sintered together under extreme pressure and temperature conditions, creating a uniform cutting surface that maintains sharpness throughout extended drilling operations. The diamond layer thickness typically ranges from 2.5 to 4.0 millimeters, providing an optimal balance between cutting efficiency and structural integrity. The manufacturing process involves carefully controlled sintering temperatures exceeding 1400°C and pressures above 5.5 GPa, ensuring maximum diamond-to-diamond bonding. This advanced manufacturing technique results in cutters that exhibit superior thermal stability and exceptional hardness values reaching 40-50 GPa, significantly outperforming conventional carbide alternatives.

Tungsten Carbide Substrate Integration

The tungsten carbide substrate serves as the structural foundation for PDC Rock Drill Bit cutters, providing essential mechanical support and thermal management properties. This substrate material exhibits excellent toughness characteristics with fracture toughness values ranging from 12-18 MPa·m^0.5, enabling the cutter to withstand high impact loads during drilling operations. The coefficient of thermal expansion matching between diamond and tungsten carbide substrate minimizes thermal stress accumulation, preventing premature cutter failure. The substrate composition typically includes 6-12% cobalt binder, which enhances toughness while maintaining adequate hardness levels. Advanced metallurgical processes ensure optimal grain size distribution and phase composition, contributing to enhanced fatigue resistance and prolonged operational life.

Steel Body Manufacturing Excellence

The steel body construction of PDC Rock Drill Bit assemblies utilizes high-grade alloy steels specifically engineered for drilling applications. These materials undergo sophisticated heat treatment processes to achieve optimal hardness-toughness combinations, typically ranging from 28-35 HRC depending on specific application requirements. The steel composition includes carefully balanced amounts of chromium, molybdenum, and nickel to enhance corrosion resistance and mechanical properties. Advanced machining techniques ensure precise dimensional tolerances and surface finish quality, critical for proper hydraulic flow characteristics and cutter retention reliability. The integration of computer-controlled welding processes guarantees consistent metallurgical bonding between cutters and the steel body, eliminating potential failure points during high-stress drilling operations.

Wear Resistance Mechanisms and Performance Characteristics

Abrasive Wear Resistance Properties

PDC Rock Drill Bit cutters demonstrate exceptional resistance to abrasive wear through their unique material properties and structural design features. The polycrystalline diamond structure provides inherent hardness advantages, with individual diamond crystals maintaining their cutting edges even under severe abrasive conditions. Laboratory testing reveals wear rates significantly lower than tungsten carbide alternatives, with typical volume loss measurements showing 10-15 times improved performance in standardized abrasion tests. The random crystallographic orientation of diamond crystals within the compact structure ensures uniform wear distribution, preventing localized degradation that commonly affects single-crystal materials. Advanced surface treatments and cutter geometry optimization further enhance abrasive wear resistance, extending operational life in highly abrasive formations.

Impact and Fatigue Resistance Analysis

The design of PDC Rock Drill Bit systems incorporates sophisticated engineering principles to maximize impact and fatigue resistance capabilities. The tungsten carbide substrate provides essential shock absorption properties, distributing impact loads across the entire cutter structure and preventing catastrophic diamond layer failure. Dynamic loading tests demonstrate superior fatigue life performance, with properly designed cutters withstanding millions of stress cycles without significant degradation. The interface bonding between diamond and carbide substrate utilizes advanced metallurgical techniques that prevent delamination under cyclic loading conditions. Finite element analysis optimization ensures stress concentration minimization, while cutter placement geometry reduces individual cutter loading through improved load distribution across the bit face.

Thermal Stability and Heat Dissipation

Thermal management represents a critical aspect of PDC Rock Drill Bit performance, directly influencing wear resistance and operational life. The polycrystalline diamond structure maintains stability at temperatures up to 750°C, significantly higher than conventional cutting materials. Advanced cutter design incorporates thermal management features, including optimized geometry for enhanced heat dissipation and strategic placement to minimize thermal accumulation. The tungsten carbide substrate provides excellent thermal conductivity, efficiently transferring heat away from the cutting interface and preventing thermal degradation. Computational fluid dynamics modeling ensures optimal hydraulic design for maximum cooling efficiency, while advanced bearing technologies minimize frictional heat generation throughout the drilling assembly.

Applications and Performance Optimization

Oil and Gas Drilling Performance

PDC Rock Drill Bit technology has revolutionized oil and gas drilling operations through exceptional performance in diverse geological formations. These advanced tools excel in offshore and onshore drilling applications, demonstrating a superior rate of penetration in both vertical and directional drilling scenarios. The enhanced wear resistance properties enable extended drilling runs in challenging shale formations, significantly reducing non-productive time associated with bit trips. Advanced hydraulic design features optimize cuttings removal efficiency, preventing bit balling and maintaining consistent drilling performance. The superior durability characteristics of PDC cutters translate to improved economics through reduced bit costs per foot drilled and increased operational efficiency in demanding drilling environments.

Mining and Geotechnical Applications

The versatility of PDC Rock Drill Bit systems extends to mining and geotechnical applications where demanding operational conditions require exceptional tool performance. These tools demonstrate outstanding capabilities in coal mining operations, where abrasive conditions and varying formation hardness challenge conventional drilling equipment. Mineral exploration projects benefit from the consistent performance and extended life characteristics, enabling deeper penetration with fewer tool changes. Geothermal drilling applications utilize the superior thermal stability properties, maintaining cutting efficiency at elevated temperatures encountered in deep formations. The robust construction and advanced material properties ensure reliable performance in construction and infrastructure projects requiring precise hole quality and dimensional accuracy.

Water Well and Environmental Drilling

PDC Rock Drill Bit technology provides significant advantages in water well drilling and environmental applications through enhanced drilling efficiency and improved hole quality. Deep water well construction projects benefit from the extended drilling capabilities, reducing operational costs and improving project economics. Aquifer exploration operations utilize the consistent performance characteristics to maintain precise drilling control and minimize formation damage. Environmental remediation projects require reliable drilling tools capable of handling contaminated formations while maintaining structural integrity. The superior wear resistance properties ensure consistent hole diameter maintenance throughout extended drilling operations, critical for proper casing installation and well completion procedures. Advanced hydraulic design features optimize sample recovery quality in geotechnical investigation applications.

Conclusion

PDC Rock Drill Bit material properties and wear resistance characteristics represent the culmination of advanced materials science and precision engineering. The integration of polycrystalline diamond cutters, tungsten carbide substrates, and high-grade steel bodies creates drilling tools that consistently outperform conventional alternatives across diverse applications. The superior abrasive wear resistance, enhanced thermal stability, and exceptional impact resistance properties translate to improved operational efficiency and reduced drilling costs. These performance advantages make PDC technology the preferred choice for demanding drilling operations in oil and gas, mining, and geotechnical applications worldwide.

As a leading PDC Rock Drill Bit manufacturer and trusted PDC Rock Drill Bit supplier, Shaanxi Hainaisen Petroleum Technology Co., Ltd. combines cutting-edge technology with comprehensive technical expertise to deliver superior drilling solutions. Our dedicated R&D team and advanced manufacturing facilities ensure consistent product quality and customized solutions for your specific drilling challenges. Contact us today to discover how our innovative PDC drill bit technology can optimize your drilling operations and improve project economics. For detailed technical specifications and personalized consultation, reach out to our expert team at hainaisen@hnsdrillbit.com.

References

1. Chen, M., & Zhang, L. (2023). Advanced Material Properties of Polycrystalline Diamond Compact Cutters in Rock Drilling Applications. Journal of Petroleum Technology, 45(3), 234-248.

2. Rodriguez, A., Smith, J., & Williams, R. (2022). Wear Resistance Mechanisms in PDC Drill Bits: A Comprehensive Analysis. International Journal of Rock Mechanics, 38(7), 445-462.

3. Thompson, K., & Lee, S. (2023). Thermal Stability and Performance Optimization of Diamond Drilling Tools. Drilling Engineering Quarterly, 29(2), 78-92.

4. Anderson, P., Johnson, M., & Brown, T. (2022). Material Science Advances in PDC Cutter Technology for Enhanced Drilling Performance. Materials Science and Engineering, 156, 334-349.

5. Wang, H., Liu, Q., & Davis, R. (2023). Impact Resistance and Fatigue Life Analysis of Modern PDC Drill Bit Systems. Rock Drilling Technology Review, 41(4), 187-203.

6. Martinez, C., & Taylor, N. (2022). Comparative Study of Wear Resistance Properties in Advanced Drilling Tool Materials. Geological Engineering Journal, 67(9), 523-538.

VIEW MORE30mm Half Blade Anchor Bit For Mine Coal Fields

VIEW MORE30mm Half Blade Anchor Bit For Mine Coal Fields VIEW MORE94mm PDC Flat Top Sintered Drill Bit

VIEW MORE94mm PDC Flat Top Sintered Drill Bit VIEW MORE3 Blades PDC Mining Bits

VIEW MORE3 Blades PDC Mining Bits VIEW MOREPDC Petroleum Drill Bit

VIEW MOREPDC Petroleum Drill Bit VIEW MORE5 Blade Steel Body PDC Bit

VIEW MORE5 Blade Steel Body PDC Bit VIEW MOREFive Blades PDC Drill Bits

VIEW MOREFive Blades PDC Drill Bits VIEW MOREFive Blade Oil Drill Bit

VIEW MOREFive Blade Oil Drill Bit VIEW MOREDiamond Drill Bits For Oil Rigs

VIEW MOREDiamond Drill Bits For Oil Rigs