What are the key components of 3-blade directional bits?

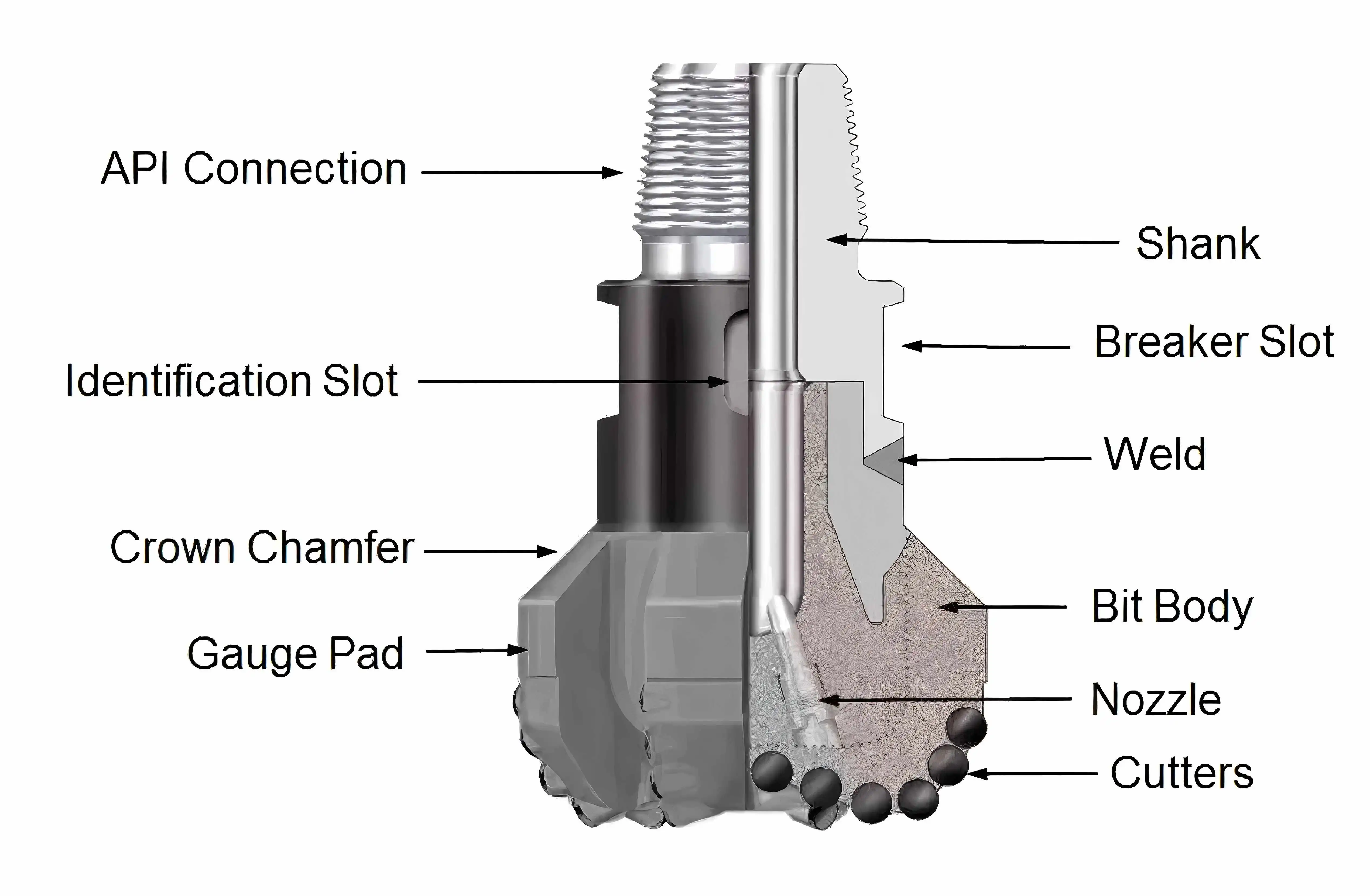

A Directional Three Blade PDC Drill Bit's efficiency is derived from its well-designed parts, each of which is essential to the tool's overall functionality. Let's examine the key components that distinguish these bits in the drilling sector:

PDC Cutters

The polycrystalline diamond compact (PDC) cutters are the central component of the bit's cutting action. These cutting-edge materials are made of diamond particles that have been sintered together at high temperatures and pressures to provide an extremely hard cutting surface. To maximize cutting efficiency and wear resistance, the PDC cutters are positioned strategically on the bit's blades, allowing the bit to keep its sharp edge even in abrasive conditions.

Steel Body

All other parts are supported by the bit's body, which is usually made of high-strength steel. This sturdy construction is made to resist the high temperatures and forces that are present during drilling operations. In order to cool the bit and remove cuttings from the wellbore, the steel body also has internal fluid tunnels that allow drilling mud to circulate.

Blades

The three blades are perhaps the most distinctive feature of this bit design. Each blade is carefully contoured and positioned to achieve an optimal balance between cutting aggressiveness and stability. The blade design plays a significant role in controlling the bit's directional tendencies and its ability to maintain a straight or curved wellbore path as required.

Nozzles

Nozzles that are put in the right places direct the flow of drilling fluid across the bit face and cutters. This hydraulic optimization makes the cutter cooler, removes the cutting better, and improves the general efficiency of the drilling. The bit's success in different types of formation depends on where and how big these nozzles are placed.

Gauge Pads

Gauge pads on the side of the bit body help keep the hole's width steady and make the bit more stable. When used in directional applications, these pads are very important because they keep the bit from wandering off the planned path, which improves the overall directional control.

Material and structural features for directional control

The Directional Three Blade PDC Drill Bit incorporates several material and structural features specifically designed to enhance directional control during drilling operations. These features work in concert to provide operators with precise steering capabilities and improved wellbore quality:

Asymmetric Blade Configuration

The three-blade design allows for an asymmetric blade configuration, which is crucial for directional control. By varying the blade lengths and positions, engineers can create a bit with a natural tendency to drill in a particular direction. This inherent directional bias can be leveraged by drillers to maintain or alter the wellbore trajectory as needed.

Cutter Placement and Orientation

The strategic placement and orientation of PDC cutters on each blade significantly influence the bit's directional behavior. By carefully adjusting the back rake and side rake angles of individual cutters, designers can fine-tune the bit's cutting action to achieve the desired balance between aggressiveness and stability. This precise cutter arrangement allows for smoother directional changes and reduces the likelihood of unwanted deviations.

Variable Gauge Length

Incorporating a variable gauge length into the bit design enhances its directional capabilities. A longer gauge section near the bit face provides increased stability and helps maintain a straighter wellbore, while a shorter gauge towards the back allows for more aggressive directional changes when needed. This dual-functionality gauge design offers drillers greater flexibility in controlling the well path.

Material Selection for Thermal Stability

What kind of materials are used to make the bit body and blades is very important for keeping control of the direction in hot places. New PDC cutter materials that are more resistant to wear and have better thermal stability keep cutting well even in the harshest situations downhole. In the same way, the steel body is made to survive high temperatures without losing its structural integrity. This makes sure that the bit always works in the same direction.

Hydraulic Optimization

Controlling the direction of flow depends a lot on how the fluid pathways and nozzles are built and placed inside the bit structure. Engineers can improve the cooling and cutting removal efficiency of a cutter by adjusting the fluid flow across the bit face. This not only improves the general performance of the drill, but it also helps with more accurate direction control by making sure that all of the blades cut in the same way.

How three-blade design enables precise steering?

The Directional Three Blade PDC Drill Bit's three blades aren't just there to look good; they're carefully designed to give you precise steering and better directional control. The bit works very well in directional drilling because of its special structure, which has a number of benefits:

Reduced Lateral Vibration

During cutting, the three-blade design reduces side-to-side vibrations as much as possible. This shape helps keep the drilling axis steady by spreading the cutting forces more evenly around the bit's edge. This lower vibration not only makes drilling more efficient overall, but it also makes it easier for the driller to make exact changes in direction without going off track.

Optimized Force Distribution

With three blades, the bit can find the best mix between cutting quickly and steering smoothly. The forces that are created during drills are spread out in a way that makes it easier to switch directions. This even spread of force makes the directional responses more predictable and manageable, which gives operators more control over the wellbore's path.

Enhanced Steerability in Various Formations

Superior steerability is offered by the three-blade configuration in a variety of formation types. Engineers may design bits that react reliably to steering inputs in soft, medium, and hard forms by precisely adjusting the blade shape and cutter placement. This adaptability is especially useful in intricate geological settings where directional control can be greatly impacted by formation changes.

Improved Toolface Control

Directional drilling requires good control over the toolface, and the three-blade design does this very well. While drilling, the balanced cutting structure makes it easier to precisely control the bit's direction, which helps them keep the desired toolface angle more accurately. Higher control means smoother wellbore paths and less twisting, which improves well performance and makes finishing operations easier.

Efficient Cleaning and Cooling

The three-blade design makes the junk holes between the blades bigger, which makes it easier to remove drill cuttings and better circulates drilling fluid. This improved hydraulic performance helps keep the PDC cuts cooler and cleans the wellbore more effectively. So, even in tough drilling conditions, the bit keeps cutting well and responding quickly to changes in direction. This makes sure that the turning works the same way throughout the run.

Conclusion

The Directional Three Blade PDC Drill Bit speaks to a critical headway in penetrating innovation, advertising unparalleled execution in directional penetrating applications. Its carefully designed components, materials, and auxiliary highlights work in agreement to give extraordinary strength, cutting productivity, and exact directing capabilities. Whether you're included in oil and gas investigation, coal mining, or geotechnical ventures, these imaginative bore bits can altogether upgrade your boring operations.

FAQ

1. What are the main advantages of using a Directional Three Blade PDC Drill Bit?

Directional Three Blade PDC Drill Bits have many benefits, such as better control over direction, higher entry rates, and better resistance to wear. Because of how they are made, they can be precisely guided through different types of rock, which makes them perfect for difficult digging projects.

2. How does the three-blade design compare to other bit configurations?

The three-blade design strikes the perfect mix between cutting power and stability. It has bigger junk slots than bits with more blades, so it cleans and cools better, and you can still control the direction of the bit very well. Most of the time, this arrangement makes drilling go more smoothly and gives more consistent results across different formations.

3. Can Directional Three Blade PDC Drill Bits be customized for specific drilling conditions?

Yes, these bits can be changed to fit the needs of a certain job. Blade profile, cutter placement, and material choice are some of the things that can be changed to get the best results in certain rock formations or drilling conditions. If you buy from a reputable company, you can be sure that the bit shape will fit your needs perfectly.

4. What maintenance is required for Directional Three Blade PDC Drill Bits?

Even though PDC bits are known for being strong, they can last even longer if they are properly maintained. This usually means checking it often for damage or wear, cleaning it properly after use, and being careful when transporting it. To get the most out of the bit's durability and usefulness, it's important to follow the manufacturer's instructions for care and use.

Directional Three Blade PDC Drill Bit Manufacturers | HNS

Looking for a reliable manufacturer of high-quality Directional Three Blade PDC Drill Bits? Look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. Our state-of-the-art factory and team of experienced engineers work together to make cutting-edge drilling tools that meet the highest standards in the business. We can tailor our services to your exact drilling needs, so you can be sure of getting the best results even in the most difficult conditions. Our Directional Three Blade PDC Drill Bits can help you drill more accurately and quickly, no matter if you work in coal mining, oil and gas development, or geotechnical engineering. Don't skimp on quality; if you need drilling tools, choose HNS. Contact us today at hainaisen@hnsdrillbit.com to discuss how we can elevate your drilling operations with our state-of-the-art PDC drill bits.

References

1. Smith, J.R. et al. (2020). "Advancements in Directional Drilling: The Role of Three Blade PDC Bits." Journal of Petroleum Technology, 72(5), 45-52.

2. Brown, M.E. (2019). "Material Innovations in PDC Cutter Technology." SPE Drilling & Completion, 34(2), 121-135.

3. Chen, Y. and Li, X. (2021). "Hydraulic Optimization of PDC Bits for Enhanced Directional Control." International Journal of Rock Mechanics and Mining Sciences, 138, 104648.

4. Thompson, K.L. (2018). "Structural Design Considerations for Directional PDC Bits." Offshore Technology Conference, Houston, Texas, USA, OTC-28954-MS.

5. Wilson, A.C. and Davis, R.M. (2022). "Comparative Analysis of Three-Blade vs. Multi-Blade PDC Bits in Directional Drilling Applications." SPE/IADC Drilling Conference and Exhibition, Galveston, Texas, USA, SPE-208770-MS.

6. Zhao, H. et al. (2023). "Thermal Stability Enhancements in PDC Cutters for High-Temperature Drilling Environments." Wear, 516-517, 204374.