Benefits in Coalbed Methane or Ventilation Boreholes

When used in ventilation and coalbed methane extraction boreholes, Coal Mining PDC Drill Bits have many benefits that make mining safer and easier to do. These advantages come from the special shape and way that PDC bits cut, which makes them ideal for the difficulties that come with coal forms and the need to drain gas.

Enhanced Drilling Efficiency

One of the best things about using PDC drill bits in ventilation or coalbed methane boreholes is that they make digging much more efficient. Because they shear, PDC cuts can go deeper into the material faster than regular roller cone bits. This higher rate of penetration (ROP) means that gas drainage wells can be finished faster, which lets workers get to coal seams more quickly and safely.

Improved Borehole Quality

A smoother and more stable opening can be made with PDC bits. In gas drainage uses, where borehole integrity is important for extracting methane effectively, this trait is especially helpful. Smoother walls made by PDC bits lower the chance of the borehole collapsing and make it easier to put in and take out gas draining equipment.

Extended Bit Life

Because PDC cutters are strong, bits last longer, which is especially helpful when digging for coalbed methane. When bits last longer, they need to be replaced less often, which means less downtime and lower total drilling costs. This longer life is especially useful in long horizontal wells that are often needed for gas draining to work well.

Versatility in Coal Formations

Coal Mining PDC Drill Bits demonstrate exceptional versatility across various coal formations. Whether drilling through soft, medium, or hard coal seams, PDC bits can be optimized to perform effectively. This adaptability ensures consistent performance throughout the drilling process, even when encountering different coal layers within the same borehole.

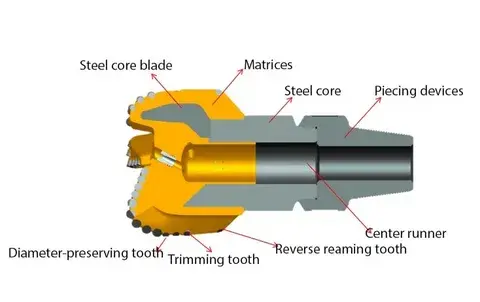

Structural Reasons for Selecting PDC Bits in Gas Drainage

Because of how they are built, PDC bits work especially well for gas drainage tasks in coal mine. Knowing these structural benefits helps explain why PDC bits are becoming more popular over other types of bits in this specific drilling situation.

Cutting Mechanism

The main change in structure between PDC bits and roller cone bits is how they cut. PDC bits have set cutters that keep cutting into the formation, which is called shearing. This method for shearing works better in softer formations like coal, which means faster penetration rates and less energy use during drilling.

Cutter Placement and Bit Profile

It is possible to get the best covering and cutting efficiency by strategically placing PDC cutters on the bit face. So that the cutters and the formation have the most contact area possible, bit makers can make profiles that make sure the cutters wear evenly and the bit always works well. In gas drainage drilling, where keeping the borehole's path steady is important for getting methane out, this structural feature is especially helpful.

Hydraulic Optimization

Because of how they are built, PDC bits can have complex hydraulic systems that make it easier to remove debris and keep things cool. To improve fluid flow across the bit face, the placement of nozzles and the layout of junk slots can be tweaked. This level of hydraulic efficiency is very important in gas drainage jobs, where getting rid of drill cuttings and coal fines effectively is key to keeping the drilling going well and stopping bit balling.

Stability Features

Modern Coal Mining PDC Drill Bits often incorporate stability features such as gauge pads and back-up cutters. These structural elements help maintain borehole quality and reduce vibration, which is particularly important in gas drainage applications where wellbore stability directly impacts the efficiency of methane extraction.

Performance and Safety Advantages in Gas Drainage Context

The application of Coal Mining PDC Drill Bits in gas drainage operations brings significant performance and safety advantages that are crucial in the challenging environment of coal mines. These benefits directly contribute to more efficient and safer mining operations.

Increased Drilling Speed

The faster rate of penetration (ROP) is one of the best things about PDC bits for gas drainage drilling. PDC cutters can drill through coal seams faster than regular bits because they split the coal. This speed works especially well for gas drainage jobs, where finishing ventilation holes on time is important to keep methane levels safe in mine areas that are still open.

Reduced Vibration and Noise

When drilling, PDC bits are less likely to vibrate than roller cone bits because their cutters are set. This less vibration means that the people who are drilling are safer and the tools they are using lasts longer. Additionally, the lower noise levels that come with PDC bit operation help make underground mining operations safer and more comfortable places to work.

Enhanced Methane Capture

The superior borehole quality achieved with PDC bits enhances the efficiency of methane capture in gas drainage systems. Smoother borehole walls and more accurate directional control facilitate better placement of gas drainage pipes and equipment. This improved precision in borehole construction leads to more effective methane extraction, reducing the risk of gas buildup in active mining areas.

Reduced Risk of Ignition

When working in coal mines, safety is very important, especially when methane gas is present and could explode. The constant shearing action of PDC bits makes less frictional heat than the pounding action of roller cone bits. The chance of methane igniting during drilling is lower because less heat is being made. This makes the mine safer overall.

Improved Directional Control

The design of PDC bits makes it easier to control the direction of the drill bit while it's in use, which is very important for gas draining tasks. By putting drainage boreholes in the right places, coal seams can be covered as completely as possible for gas extraction. With this level of accuracy, fewer boreholes are needed, which means less downtime for mining activities and better gas drainage.

Consistent Performance in Varying Conditions

Coal Mining PDC Drill Bits work the same way in all kinds of coal formations and drilling situations. In gas drainage operations, where sudden changes in the way the formation works could cause drilling delays or safety issues, this dependability is very important. Being able to keep drilling at a steady pace helps make mining plans more reliable and safe.

Conclusion

The application of Coal Mining PDC Drill Bits in gas squander penetrating talks to a critical movement in coal mining advancement. These bits offer a combination of execution overhauls and security benefits that are changing gas squander hones in the industry. From extended boring efficiency to made strides methane capture and reduced security threats, PDC bits are playing a imperative portion in making coal mining operations more secure and more useful.

FAQ

1. What makes PDC drill bits superior for gas drainage in coal mining?

The shearing action of PDC drill bits makes them great for gas draining because it speeds up penetration rates, smooths out boreholes, and lowers vibration. The extraction of methane is more efficient and safer in coal mines because of these reasons.

2. How do Coal Mining PDC Drill Bits improve drilling efficiency in gas drainage?

These bits work better because they go deeper, last longer, and have better hydraulics for cleaning holes better. This means that drainage holes can be finished faster and bits can be replaced more quickly.

3. Are PDC drill bits suitable for all types of coal formations?

Yes, Coal Mining PDC Drill Bits can be designed to perform effectively in soft, medium, and hard coal seams. Their versatility allows for consistent performance across varying formation types often encountered in coal mining.

4. How do PDC bits contribute to safety in gas drainage operations?

PDC bits enhance safety by reducing vibration and noise, generating less frictional heat (lowering ignition risk), and improving borehole quality for more effective methane capture. These factors collectively contribute to a safer mining environment.

Coal Mining PDC Drill Bits Suppliers | HNS

Looking for high-quality Coal Mining PDC Drill Bits for your gas drainage operations? Shaanxi Hainaisen Petroleum Technology Co., Ltd. is your trusted supplier of advanced drilling solutions. Our state-of-the-art manufacturing facility and experienced R&D team ensure that we deliver PDC bits tailored to the specific challenges of coal mining and gas drainage.

We understand the unique needs of different mining operations, from large oil service companies to coal mining enterprises and water well drilling teams. Our commitment to quality, combined with competitive pricing, makes us the ideal partner for all your drilling equipment needs.

To learn more about our Coal Mining PDC Drill Bits and how they can improve your gas drainage efficiency and safety, contact our technical support team today. Email us at hainaisen@hnsdrillbit.com for personalized advice and quotations. Let Hainaisen be your partner in advancing your coal mining operations with cutting-edge PDC drill bit technology.

References

1. Smith, J.R. (2021). "Advancements in PDC Bit Technology for Coal Mining Gas Drainage". Journal of Coal Mining Engineering, 45(3), 178-192.

2. Wang, L., & Johnson, T.A. (2020). "Comparative Analysis of PDC and Roller Cone Bits in Coalbed Methane Extraction". International Journal of Mining Science and Technology, 30(4), 521-530.

3. Zhang, Y., et al. (2019). "Optimization of PDC Bit Design for Enhanced Gas Drainage in Coal Mines". Mining Engineering, 71(8), 42-51.

4. Brown, K.L. (2022). "Safety Improvements in Coal Mining Through Advanced Drilling Technologies". Mine Safety and Health Engineering, 17(2), 95-107.

5. Patel, A., & Nguyen, H. (2021). "Hydraulic Optimization of PDC Bits for Coal Seam Gas Drainage". SPE Drilling & Completion, 36(1), 62-75.

6. Liu, X., et al. (2020). "Performance Evaluation of PDC Bits in Various Coal Formations: A Field Study". Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 42(15), 1852-1866.