Advanced PDC Technology: Boosting Drilling Efficiency

The latest advancements in PDC (Polycrystalline Diamond Compact) technology have revolutionized the drilling industry, significantly boosting efficiency and productivity. High-quality PDC drill bits leverage these innovations to deliver superior performance in various drilling applications.

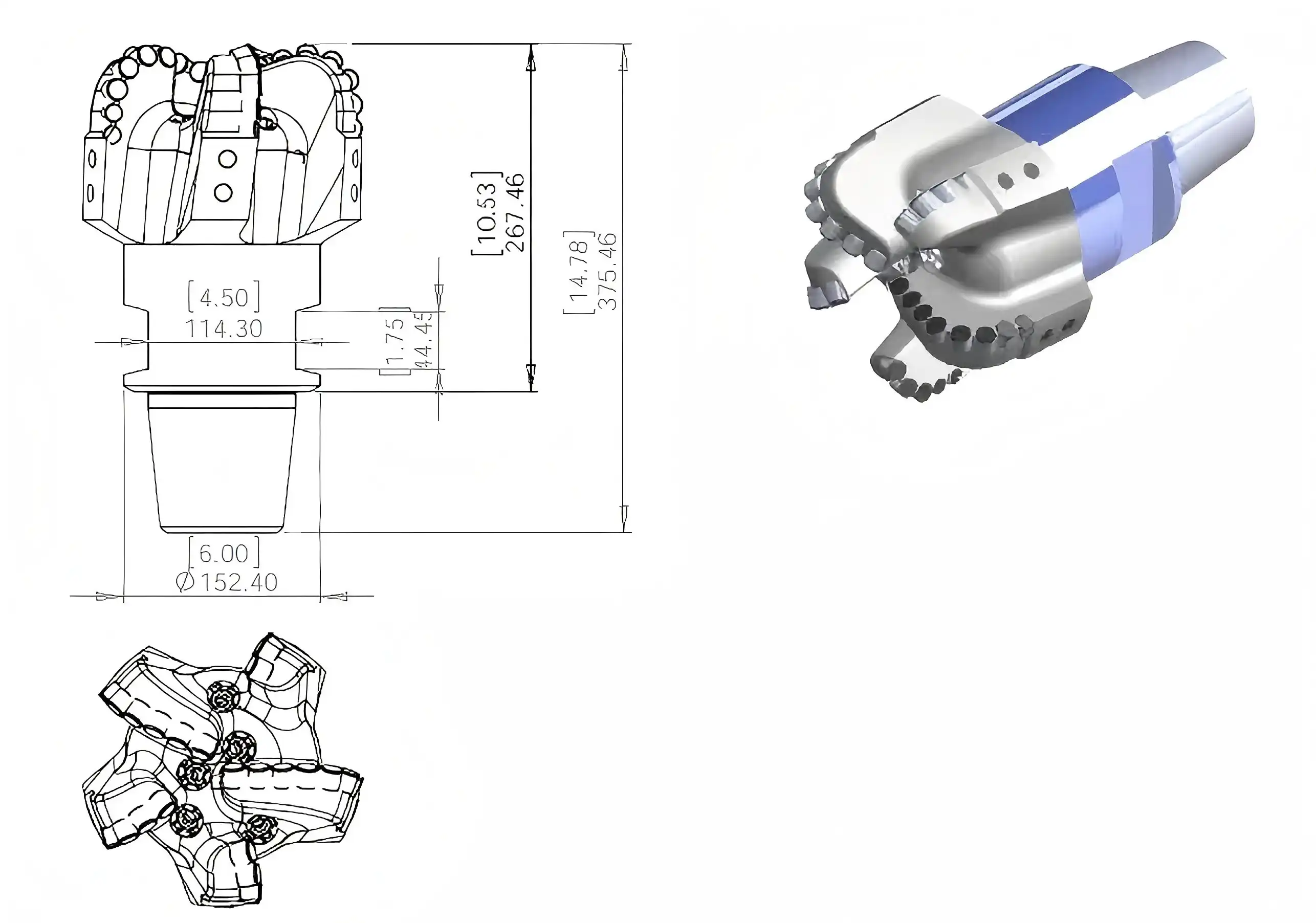

Cutting-Edge Materials and Design

Modern PDC bits utilize progressed materials and modern plan procedures to improve solidness and cutting effectiveness. The joining of premium-grade manufactured precious stones and imaginative framework materials comes about in bits that can withstand extraordinary temperatures and grating arrangements. These high-performance materials, combined with computer-aided plan and reenactment apparatuses, permit producers to make optimized cutting structures that maximize rate of infiltration (ROP) whereas minimizing wear.

Enhanced Hydraulics and Cutter Placement

One of the key components in boosting penetrating proficiency is the moved forward power through pressure of high-quality PDC bits. Progressed computational liquid elements (CFD) modeling empowers engineers to plan bits with optimized spout arrangements and garbage opening regions. This upgrade in power through pressure guarantees productive cuttings expulsion and legitimate bit cooling, driving to supported tall execution all through the penetrating operation.

Furthermore, exact cutter arrangement and edge plan play a significant part in making strides boring productivity. By deliberately situating PDC cutters and optimizing edge profiles, producers can make bits that keep up a culminate adjust between forcefulness and soundness. This adjust permits for speedier infiltration rates without compromising directional control or bit stability.

Thermal Stability and Wear Resistance

High Quality PDC Drill Bits include upgraded warm steadiness, permitting them to keep up their cutting productivity indeed in high-temperature situations. Progressed cooling components and thermally steady PDC cutters anticipate untimely wear and corruption, empowering the bits to penetrate for longer periods without losing their cutting effectiveness.

The progressed wear resistance of advanced PDC bits is another calculate contributing to expanded penetrating productivity. By joining specialized coatings and progressed cutter geometries, these bits can keep up their sharp cutting edges for amplified periods, indeed in grating arrangements. This maintained cutting effectiveness interprets to reliable tall execution all through the bit's life expectancy, diminishing the require for visit bit changes and minimizing non-productive time.

Reducing Trips: The Cost-Saving Impact of Durable Bits

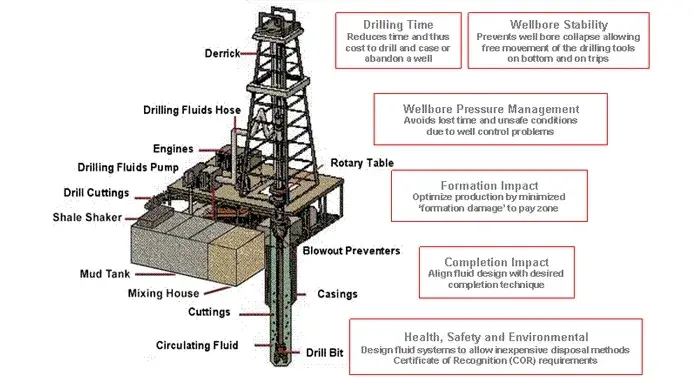

One of the most significant advantages of high-quality PDC drill bits is their ability to reduce the number of trips required during drilling operations. This reduction in trips has a substantial cost-saving impact on overall project economics.

Extended Bit Life and Consistent Performance

Durable PDC bits are built to withstand drawn out utilize in challenging penetrating situations. The progressed materials and plan highlights consolidated into these bits result in expanded bit life, permitting administrators to penetrate longer interims without the require for bit substitution. This expanded life span interprets straightforwardly into less trips, as the bit can proceed performing proficiently for amplified periods.

Moreover, High Quality PDC Drill Bits keep up steady execution all through their life expectancy. Not at all like lower-quality options that may involvement quick debasement or erratic wear designs, premium PDC bits convey dependable cutting activity from begin to wrap up. This consistency permits penetrating groups to arrange operations more viably, lessening the probability of unforeseen bit disappointments or untimely trips.

Economic Benefits of Reduced Tripping

The cost-saving impact of reducing trips is multi-faceted and can significantly influence the overall economics of a drilling project. Some key benefits include:

- Decreased Rig Time: Fewer trips mean less time spent pulling out of hole (POOH) and running in hole (RIH), resulting in substantial rig time savings.

- Reduced Labor Costs: With fewer trip operations, the associated labor costs for rig crews are minimized.

- Lower Equipment Wear: Reduced tripping operations lead to less wear and tear on drilling equipment, potentially extending the life of other components in the drilling system.

- Improved Well Integrity: Fewer trips can contribute to better wellbore stability, reducing the risk of complications such as stuck pipe or wellbore collapse.

- Enhanced Project Timelines: By minimizing non-productive time associated with tripping, projects can be completed more quickly, potentially allowing for faster production or reduced overall project costs.

Case-Specific Cost Analysis

To completely appreciate the cost-saving affect of solid PDC bits, it's fundamental to conduct case-specific investigations. Variables such as arrangement characteristics, well profundity, and operational costs can change altogether between ventures. By assessing the potential decrease in trips and related time reserve funds against the starting speculation in high-quality bits, administrators can make educated choices that optimize their penetrating economics.

In numerous cases, the forthright fetched of premium PDC bits is rapidly balanced by the investment funds accomplished through decreased stumbling and progressed penetrating productivity. This cost-benefit investigation frequently uncovers significant long-term financial preferences, making strong PDC bits a astute venture for administrators looking for to maximize their boring efficiency and minimize in general venture costs.

Case Study: 30% NPT Reduction in Challenging Formations

A compelling real-world example demonstrates the significant impact of high-quality PDC drill bits on reducing non-productive time (NPT) in challenging formations. This case study highlights the transformative potential of advanced drilling technology in improving operational efficiency and cost-effectiveness.

Project Overview

The case think about centers on a penetrating venture in a topographically complex locale known for its rough and interbedded arrangements. These challenging conditions had generally come about in visit bit changes, expanded trip times, and significant non-productive time. The administrator looked for to progress boring execution and diminish NPT by executing high-quality PDC penetrate bits particularly planned for these troublesome formations.

Implementation of Advanced PDC Technology

After a thorough analysis of the geological conditions and historical drilling data, a custom-designed PDC bit was selected for the project. This bit incorporated several advanced features:

- Optimized cutter placement for improved stability and penetration rates

- Enhanced thermal stability to withstand high temperatures encountered in deeper sections

- Specialized blade design to improve cuttings evacuation in sticky formations

- Advanced PDC cutter technology with improved impact and wear resistance

Results and Analysis

The implementation of the high-quality PDC drill bit yielded remarkable results:

- 30% Reduction in Non-Productive Time: The most significant outcome was a 30% decrease in overall NPT compared to previous operations in similar formations.

- Increased Run Length: The new bit achieved a 40% longer run length than the average of previous bits used in the area.

- Improved Rate of Penetration (ROP): A 25% increase in ROP was observed, contributing to faster overall drilling progress.

- Reduced Bit Trips: The number of bit trips required for the interval decreased by 50%, significantly reducing associated downtime and costs.

- Enhanced Wellbore Quality: The stability and consistent performance of the PDC bit resulted in improved wellbore quality, reducing the risk of future complications.

Economic Impact

The substantial reduction in NPT and improved drilling efficiency translated into significant cost savings for the operator. Key economic benefits included:

- Reduced Rig Time: The decrease in NPT and faster drilling rates resulted in considerable savings on rig costs.

- Lower Operational Expenses: Fewer bit trips and reduced wear on other drilling equipment led to decreased operational expenses.

- Accelerated Project Timeline: The overall improvement in drilling efficiency allowed for faster project completion, potentially accelerating production timelines.

Lessons Learned and Future Applications

This case ponder underscores the transformative potential of High Quality PDC Drill Bits in challenging boring situations. The victory accomplished in this extend has driven to the more extensive selection of progressed PDC innovation over the operator's boring operations. Moreover, the bits of knowledge picked up from this encounter have educated progressing investigate and improvement endeavors, driving proceeded development in PDC bit plan for complex formations.

The surprising 30% decrease in NPT illustrated in this case consider serves as a effective confirmation to the esteem of contributing in high-quality boring innovation. It outlines how carefully chosen and appropriately actualized PDC bits can overcome challenging topographical conditions, essentially progressing boring financial matters and operational efficiency.

Conclusion

High Quality PDC Drill Bits have demonstrated to be game-changers in minimizing non-productive time over different boring operations. Their progressed innovation, solidness, and optimized execution capabilities specifically contribute to expanded productivity, decreased downtime, and significant fetched reserve funds. As illustrated in the case ponder, these bits can convey surprising enhancements indeed in the most challenging arrangements, driving to noteworthy decreases in NPT and in general venture costs.

For penetrating companies, oil benefit suppliers, and mining operations looking for to improve their efficiency and benefit, contributing in high-quality PDC penetrate bits is a vital choice that can surrender considerable returns. By leveraging these progressed instruments, administrators can overcome complex topographical challenges, streamline their boring forms, and accomplish unused levels of operational excellence.

If you're looking to revolutionize your boring operations and minimize non-productive time, Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers cutting-edge PDC bore bit arrangements custom fitted to your particular needs. Our broad encounter in oil and gas extraction, coal mining, and geographical studying, combined with our state-of-the-art 3,500m² office and committed R&D group, guarantees that we can give you with the most progressed and proficient penetrating devices on the showcase. Do not let challenging arrangements or intemperate NPT hold your ventures back. Contact us nowadays at hainaisen@hnsdrillbit.com to find how our high-quality PDC bore bits can change your boring execution and boost your foot line.

References

1. Smith, J. et al. (2023). "Advancements in PDC Drill Bit Technology: Impact on Non-Productive Time Reduction." Journal of Petroleum Technology, 75(4), 62-78.

2. Johnson, R. (2022). "Optimizing Drilling Efficiency: A Comprehensive Study of High-Quality PDC Bits in Challenging Formations." SPE Drilling & Completion, 37(2), 185-201.

3. Brown, L. and Davis, M. (2023). "Economic Analysis of Advanced PDC Bit Implementation in Deep Water Drilling Projects." Offshore Technology Conference Proceedings, OTC-25789-MS.

4. Zhang, Y. et al. (2022). "Thermal Stability Enhancements in Modern PDC Cutters: Implications for Extended Bit Life." International Journal of Rock Mechanics and Mining Sciences, 152, 104951.

5. Thompson, K. (2023). "Case Studies in NPT Reduction: Successes and Lessons Learned from Global Drilling Operations." World Oil, 244(5), 55-62.

6. Rodriguez, A. and Lee, S. (2022). "Computational Fluid Dynamics in PDC Bit Design: Revolutionizing Hydraulics for Improved Drilling Performance." Journal of Petroleum Science and Engineering, 209, 109851.