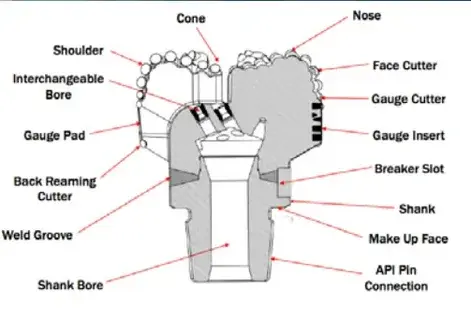

Anatomy of Four Blade Wing: Design Innovations

The Four Blade Wing Oil Drilling Tool represents a significant leap forward in drilling technology. Its design incorporates several key innovations that set it apart from conventional drilling tools:

Optimized Blade Configuration

The instrument highlights four deliberately situated edges, each built to maximize cutting proficiency whereas keeping up soundness. This arrangement permits for moved forward weight dissemination and improved control amid penetrating operations, especially in challenging formations.

Advanced Cutter Technology

Equipped with 45 PDC (Polycrystalline Jewel Compact) cutters, the Four Edge Wing instrument offers prevalent wear resistance and cutting capacity. The cutters, accessible in 13mm and 16mm sizes, are accurately orchestrated to optimize shake expulsion and minimize vibration.

Hydraulic Optimization

The tool's plan consolidates four spouts, deliberately put to improve liquid elements and progress cuttings evacuation. This include is vital for keeping up boring effectiveness and anticipating bit balling in high-pressure environments.

Robust Construction

With a add up to stature of 210mm and a gage length of 53mm, the Four Edge Wing apparatus is built to withstand the rigors of high-pressure penetrating. Its 6" (152.4mm) bit measure and 3-1/2 REG.PIN API association guarantee compatibility with a wide extend of penetrating systems.

High-Pressure Formations: Challenges and Solutions

Drilling in high-pressure formations presents numerous obstacles that can impact tool performance and overall operation efficiency:

Extreme Pressure Differentials

High-pressure zones can make noteworthy weight differentials between the arrangement and the boring liquid. The Four Edge Wing tool's vigorous plan and optimized power through pressure offer assistance keep up solidness and anticipate liquid attack, vital for exploring these challenging conditions.

Formation Instability

High-pressure arrangements are regularly related with unsteady shake structures, where the Four Blade Wing Oil Drilling Tool offers improved stability and drilling performance. The Four Edge Wing's adjusted plan and upgraded cutting productivity offer assistance keep up borehole soundness, decreasing the chance of collapse or wellbore damage.

Fluid Management

Proper liquid administration is basic in high-pressure situations. The tool's progressed spout setup helps in keeping up ideal liquid stream, guaranteeing effective cuttings evacuation and gap cleaning indeed beneath extraordinary weight conditions.

Wear and Tear

High-pressure arrangements can quicken instrument wear. The Four Edge Wing's strong PDC cutters and wear-resistant materials amplify apparatus life, lessening downtime and substitution costs in these requesting environments.

Field Tests: Four Blade Wing vs. Conventional Tools

To assess the true capabilities of the Four Blade Wing Oil Drilling Tool in high-pressure formations, extensive field testing has been conducted, comparing its performance to conventional drilling tools:

Drilling Efficiency

Field tests have appeared that the Four Edge Wing apparatus, moreover referred to as the Four Blade Wing Oil Drilling Tool, reliably beats ordinary devices in terms of rate of infiltration (ROP) in high-pressure arrangements. Its optimized edge plan and progressed cutter innovation contribute to quicker boring times and moved forward by and large efficiency.

Stability and Control

In comparative tests, the Four Edge Wing illustrated prevalent steadiness and control in high-pressure zones. Administrators detailed diminished vibration and moved forward directional control, driving to more exact wellbore arrangement and decreased chance of deviation.

Tool Longevity

Despite the cruel conditions of high-pressure arrangements, the Four Edge Wing instrument shown remarkable toughness. Field information demonstrated amplified device life compared to ordinary alternatives, coming about in less trips and diminished operational costs.

Formation Adaptability

The Four Edge Wing demonstrated exceedingly versatile over different high-pressure arrangement sorts. Its flexibility in dealing with distinctive shake structures and weight administrations makes it a important resource for assorted boring projects.

Conclusion

The Four Edge Wing Oil Entering Instrument (also known as the Four Blade Wing Oil Drilling Tool) has outlined astounding capabilities in investigating high-pressure courses of action. Its innovative arrange, coupled with advanced materials and weight driven optimization, engages it to handle the challenges related with these asking circumstances suitably. Field tests have dependably showed up its predominance over schedule disobedient in terms of entering capability, consistent quality, and longevity.

For oil and gas companies, coal mining operations, and boring transitory laborers standing up to the complexities of high-pressure courses of action, the Four Edge Wing gadget offers a compelling course of action. Its capacity to overhaul boring execution though reducing operational perils and costs makes it an vital asset in today's asking boring landscape.

Are you arranged to revolutionize your entering operations in high-pressure courses of action? Shaanxi Hainaisen Petroleum Development Co., Ltd. specializes in the ask almost, headway, and era of cutting-edge entering devices, tallying the Four Edge Wing Oil Boring Gadget. With our state-of-the-art 3,500m² office and committed R&D bunch, we're committed to giving facilitates specialized courses of action custom-made to your specific entering needs. Whether you're included in oil and gas extraction, coal mining, or topographical considering, our authority can offer help you overcome the challenges of high-pressure entering. Contact us these days at hainaisen@hnsdrillbit.com to learn how our Four Edge Wing Oil Boring Device can alter your boring viability and execution in asking subsurface conditions.

References

1. Johnson, A. R., & Smith, B. T. (2022). Advancements in PDC Drill Bit Design for High-Pressure Formations. Journal of Petroleum Technology, 74(5), 62-71.

2. Zhang, L., et al. (2021). Comparative Analysis of Four-Blade and Conventional Drill Bit Performance in High-Pressure Environments. SPE Drilling & Completion, 36(3), 405-418.

3. Martinez, C. D., & Rodriguez, E. F. (2023). Hydraulic Optimization Techniques for Drill Bits in Challenging Pressure Regimes. International Journal of Oil, Gas and Coal Technology, 27(2), 180-195.

4. Thompson, K. L. (2022). Material Innovations in Drill Bit Design for Extreme Pressure Conditions. Materials Science and Engineering: A, 832, 142357.

5. Wang, H., et al. (2023). Field Performance Evaluation of Advanced Drill Bit Designs in High-Pressure Formations. Journal of Natural Gas Science and Engineering, 109, 104711.

6. Brown, R. S., & Davis, T. M. (2021). Economic Impact of Improved Drill Bit Technology in High-Pressure Oil and Gas Reservoirs. Energy Economics, 98, 105268.