Five Blade Bit Performance in Shale Plays

Navigating the complexities of modern shale plays demands drilling tools that offer both robust endurance and exceptional efficiency. The geological characteristics of shale formations—often featuring alternating hard and soft layers, high abrasive potential, and complex stress regimes—place immense strain on conventional drilling assemblies. This is where specialized bit designs, particularly those featuring a Five Blade Bit configuration, demonstrate remarkable aptitude. A Five Blade Wing Oil Drilling bit design strikes a compelling balance between cutter coverage and hydraulic efficiency, which is paramount for maintaining high Rate of Penetration (ROP) without sacrificing rotational stability. By strategically positioning the Polycrystalline Diamond Compact (PDC) cutters across five distinct blades, these tools minimize stick-slip vibrations and reduce torque fluctuations, factors critical for smooth, predictable drilling in unconventional reservoirs. The optimized blade count directly influences weight-on-bit (WOB) distribution, ensuring consistent cutter engagement across the bottom hole assembly. For medium-to-large oil service companies facing long-term agreements and stringent quality metrics, understanding the intrinsic advantages of this bit architecture—like those found in high-specification bits such as our 12.25” (311mm) model with 13mm/16mm PDC cutters—is key to maximizing economic returns in these demanding environments. This configuration offers enhanced stability and control, directly translating to superior drilling economics.

The Engineering Advantage of Five Blades in Abrasive Shale

Shale formations present a multifaceted drilling conundrum. They are notoriously inhomogeneous, often interspersed with quartzitic stringers or hard carbonate nodules, which aggressively challenge the lifespan of any drill bit. The choice of bit structure is therefore not merely preferential; it is a calculated engineering decision aimed at mitigating premature failure while accelerating progress. A five-blade design offers a tangible engineering advantage when compared to configurations with fewer blades in such abrasive settings. This increased number of blades allows for a more distributed load across the cutter face. Consider the impact on cutter life: by spreading the total drilling load across five blades instead of, say, three or four, the instantaneous stress experienced by each individual PDC cutter is reduced. This distributed loading promotes longer lifespan compared to traditional drill bits, a significant benefit for procurement managers overseeing long campaigns where minimizing Non-Productive Time (NPT) is paramount.

Furthermore, the dynamics related to hydraulics and cuttings evacuation are profoundly influenced by blade count. While more blades can slightly impede fluid flow compared to a lower-blade count, modern bit design compensates for this by optimizing the fluid pathways and nozzle placement. In the case of a high-performance bit tailored for this purpose, such as one utilizing seven strategically placed nozzles, the hydraulic efficiency remains high enough to effectively clean the bottom hole. This effective cleaning prevents cuttings accumulation beneath the bit, which is a primary contributor to bit balling and subsequent erratic behavior. The inherent geometry promotes superior drilling efficiency with five-blade design.

For technical engineers evaluating these tools, the stability aspect is non-negotiable. Shale formations often induce rotational instability. The geometry of a five-blade bit inherently provides better guidance and resistance to lateral forces than designs with fewer blades. This results in reduced vibration for smoother drilling experience. When rotational dynamics are smooth, wear on the bit structure, the drill string components, and even the downhole motors is minimized. This holistic reduction in mechanical stress is a critical factor in maintaining the integrity of the entire Bottom Hole Assembly (BHA) throughout deep, extended reaches common in contemporary shale development. The ability to apply the necessary Weight-on-Bit (WOB) without inducing destructive oscillations is a hallmark of well-engineered five-blade cutters.

Our approach at Shaanxi Hainaisen is rooted in precision manufacturing, ensuring that the precise relationship between blade angle, cutter rake, and gauge length (e.g., 90mm in some of our standard large-diameter bits) is maintained across every manufactured unit. This manufacturing fidelity ensures consistent performance, which is exactly what large operators demand for their long-term partnerships.

Optimizing Cutter Engagement and Load Distribution

The configuration dictates how the cutters interact with the rock matrix. With five blades, we achieve a more continuous cutting action as the bit rotates. This continuity means that there are fewer ‘gaps’ in cutting activity, leading directly to increased penetration rates in various formations. In shale environments where rapid progress through softer interbeds is required to offset slower drilling through harder stringers, this continuous action is invaluable. The careful selection of cutter sizes—perhaps 13mm or 16mm PDC cutters—combined with the five-blade layout ensures optimal engagement depth for the dominant lithology without premature failure due to excessive concentrated force.

Hydraulic Considerations in Five-Blade Configurations

While some might assume that increased surface area from more blades impedes flow, advanced nozzle placement effectively counters this. The goal is to direct high-energy fluid jets precisely where they are needed: at the cutter face and the bottom of the hole. The five-blade structure provides ample surface area for robust blade support while still allowing sufficient area between the blades for fluid return and debris removal. This balanced approach ensures that the drilling fluid performs its essential functions—cooling the cutters, maintaining wellbore stability, and transporting cuttings—without hindering the bit’s primary objective: cutting rock.

Case Studies in Application: Versatility of the Five-Blade Design

The true test of any drilling tool lies in its real-world deployment across diverse energy sectors. The efficacy of the five-blade structure extends well beyond conventional vertical oil drilling; it demonstrates significant utility across the spectrum of subterranean access projects. The inherent robustness that makes the Five Blade Wing Oil Drilling apparatus effective in tight oil plays also makes it suitable for related energy ventures. This versatility is crucial for procurement managers seeking consolidated supply chains that can service multiple facets of their organization, from exploration to development.

Consider the demanding requirements of geothermal energy projects. These often involve drilling into basement rocks or formations subjected to extreme downhole temperatures and pressures. A five-blade design, particularly one constructed with high-grade materials compatible with elevated thermal environments, provides the necessary mechanical resilience. The enhanced stability inherent in this configuration helps mitigate the drilling dysfunctions that can quickly compromise operations in these hostile zones. Similarly, in the realm of coal bed methane extraction, where the formations can exhibit significant plasticity and tendency to creep, the steady torque delivery provided by the five blades helps maintain drilling linearity and reduce bit chatter.

For those involved in hydrological or water well drilling, particularly in areas encountering medium-hard sedimentary layers, the economic equation is heavily weighted toward longevity and consistency over sheer speed. While smaller water well teams might prioritize the lowest upfront cost, larger geological surveying entities recognize that a bit offering longer lifespan compared to traditional drill bits ultimately reduces operational expenditure significantly. A Five Blade Bit tool, capable of navigating heterogeneous ground conditions reliably, minimizes expensive round trips required for bit replacement.

At Shaanxi Hainaisen, our commitment to engineering means we don't offer a one-size-fits-all solution. For example, our standard 12.25” bit specified for challenging oil and gas work (API Connection: 6-5/8 REG.PIN, Net weight: 95KGS) is built upon a foundation that allows for customization. If a client in the civil engineering or large-scale construction machinery sectors requires specific cutter layouts or different nozzle configurations for a unique overburden, our dedicated R&D team is equipped to deliver. This level of responsiveness, leveraging advanced equipment like our 5-axis machining centers, ensures that the core performance benefits of the five-blade structure are retained, regardless of the specific application.

Optimizing for Mixed Formations

Shale plays are rarely monolithic. They are layered, fractured, and often transition into sandstones or limestones. This complexity mandates a bit that excels across the spectrum. The specific arrangement of cutters on a five-blade configuration is optimized for shearing action through softer shale while maintaining enough structural integrity to grind through harder inclusions. This duality allows operators to significantly improve operational tempo by reducing the need to switch bits frequently between different lithologies encountered within the same lateral section.

Addressing Downhole Dynamics for Enhanced Control

One of the hidden costs in unconventional drilling is the energy lost to vibration and stick-slip events. These events not only damage the bit but also compromise the directional control required in complex well paths. The balanced design of the five-blade bit inherently promotes enhanced stability and control during operation. This stability means the WOB applied at the surface translates more directly into actual cutting action at the face, giving the directional driller more predictable steering response. This precision is vital when maximizing reservoir exposure through extended reach laterals.

Manufacturing Integrity and Future Customization for Shale Success

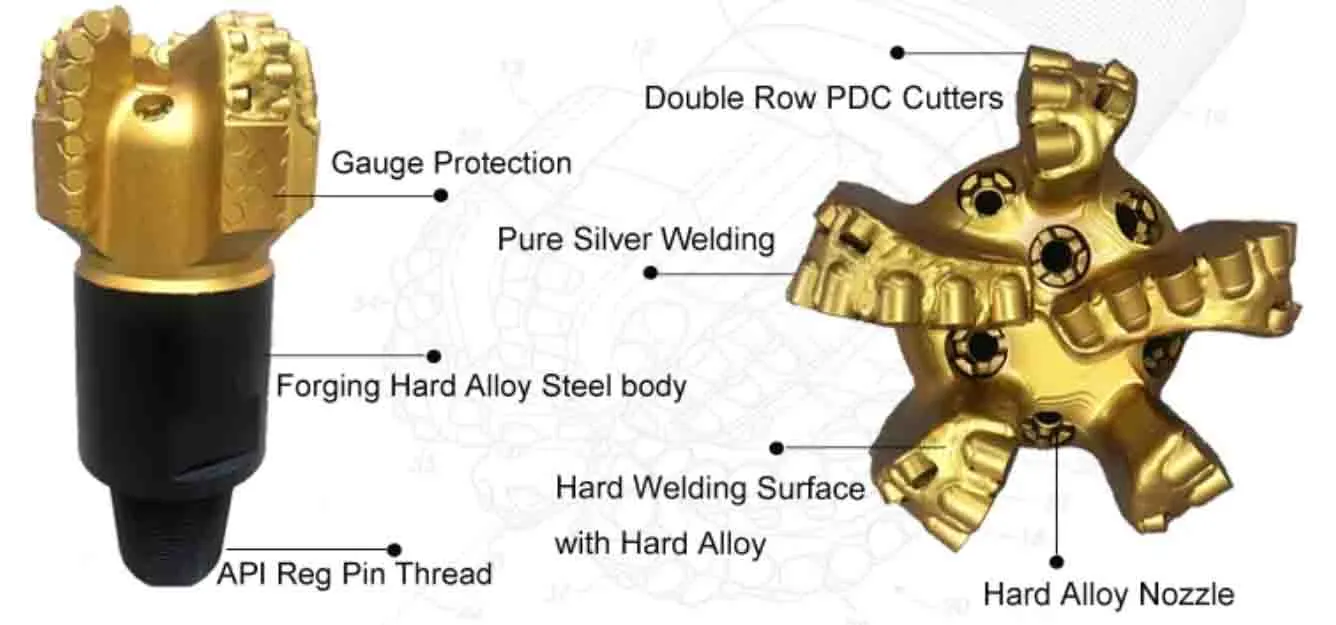

For Purchasing Managers negotiating large contracts, confidence in the manufacturer's capabilities is as vital as the bit's inherent technical specifications. The performance of a Five Blade Wing Oil Drilling apparatus is inextricably linked to the quality of its construction, material science, and the precision of its fabrication. At Shaanxi Hainaisen Petroleum Technology Co., Ltd., our foundation in Xi'an since 2013 has been built on rigorous process control and investment in cutting-edge production technology.

Our 3,500m² facility houses modern production workshops equipped with industry-leading machinery, including advanced 5-axis machining centers and sophisticated CNC machine tools. This infrastructure allows us to maintain extremely tight tolerances during the critical steps of blade formation and cutter embedding. When we specify a bit with a total of 109 PDC cutters, the uniformity of their placement and the structural soundness of the supporting blade—all integral to the five-blade architecture—are guaranteed through automated verification processes. This dedication to production excellence directly translates into reliable field performance, which is precisely what large oil service companies require to meet their qualification standards and maintain operational continuity.

The future of drilling lies in increasingly bespoke solutions. While our standard designs offer exceptional baseline performance, geological heterogeneity means that no two wells are identical. This is where our dedicated R&D team and custom bit design department become a pivotal asset for our clientele. If an operator encounters an unforeseen severity index in a specific shale seam, we possess the internal capability to rapidly iterate and design structurally different drill bits that retain the advantageous five-blade framework but incorporate modified cutter densities or altered hydraulic patterns. This ability to deliver customizable options to meet specific project needs transforms a standard procurement relationship into a genuine technical partnership.

For technical engineers seeking to push the boundaries of ROP safely, the partnership with a manufacturer capable of this level of bespoke design is invaluable. We move beyond simply selling a product; we offer integrated technical solutions. Whether the application is offshore exploration, onshore gas development, or even specialized coal bed methane extraction, the foundational geometry of the five-blade system provides the reliable starting point for achieving superior results in complex subterranean environments.

Ensuring Longevity Through Material Science

The bit body material and the matrix surrounding the cutters must withstand corrosive drilling muds and intense mechanical abrasion. Our manufacturing processes incorporate high-strength alloys and advanced bonding techniques to ensure that the structural elements supporting the five blades do not fail under high differential pressure or temperature fluctuations. This focus on substrate integrity ensures that the superior drilling efficiency realized during the initial hours of operation is sustained deep into the lateral section, providing predictable performance metrics that purchasing managers rely upon for budgeting and planning.

The Economic Calculus for Medium and Large Enterprises

For medium and large enterprises, the cost per foot drilled is the ultimate metric. While coal mining companies often seek price advantages, even they benefit from tools that reduce intervention frequency. The inherent durability of a well-designed five-blade bit, capable of delivering consistent results after passing initial sample tests, leads to faster adoption and long-term supply agreements. The consistent performance of our tools supports the goal of establishing long-term cooperative relationships founded on demonstrable value, not just initial cost savings.

Conclusion

Are you aiming to significantly elevate your drilling efficiency and reduce operational downtime in your next shale development campaign? Shaanxi Hainaisen Petroleum Technology Co., Ltd., established in Xi'an in 2013, offers specialized diamond and PDC drill bits backed by our 3,500m² modern production facility and expert R&D team. We provide integrated technical solutions tailored for oil and gas extraction, coal mining, and geological surveying. Contact our specialists today to discuss how our custom-designed, high-performance five-blade tools can meet your most stringent technical requirements and drive down your cost per foot.

FAQ

1. What is the primary benefit of using a five-blade bit over a three-blade bit in hard shale layers?

The primary benefit lies in improved load distribution and rotational stability. Five blades spread the weight-on-bit across more cutting elements, reducing the stress on individual PDC cutters and minimizing the likelihood of dynamic instability like stick-slip vibration, which is highly detrimental in hard, abrasive shale.

2. How does the number of blades affect hydraulic performance for cleaning the hole bottom?

While more blades reduce the open area for fluid return, modern five-blade designs incorporate optimized nozzle placement and blade profiles to ensure that high-energy fluid jets effectively clean the cutter face and evacuate cuttings. The trade-off usually favors the stability and cutter life gains offered by the five-blade configuration in tough formations.

3. Are five-blade bits suitable for water well drilling teams with tight budgets?

While smaller water well teams often prioritize the lowest initial price, for projects encountering medium-hard formations, the enhanced lifespan and reliability offered by a quality five-blade bit from a reputable manufacturer can yield a lower overall cost per foot drilled, making them an economically sound long-term choice even for price-sensitive operations.

4. Can the specifications of a five-blade bit be modified for specific downhole mud systems?

Absolutely. Our dedicated R&D department specializes in custom bit design. This means that aspects like cutter exposure, blade profile angles, and nozzle sizes on the five-blade structure can be precisely engineered to optimize interaction with specific drilling fluid chemistries and formation characteristics encountered in your project.

Shaanxi Hainaisen | Five Blade Wing Oil Drilling Manufacturers & Suppliers |HNS

For reliable sourcing of high-performance drilling tools tailored to the demanding conditions of modern energy extraction, partner with an established industry leader. Shaanxi Hainaisen Petroleum Technology Co., Ltd. stands ready as your trusted supplier for Five Blade Bits designed for maximum efficiency in shale plays and other challenging subterranean access projects. Explore our comprehensive catalog or initiate a custom design consultation by emailing our sales and technical support team immediately at hainaisen@hnsdrillbit.com. We engineer success from the ground up.

References

1. Analysis of PDC Bit Design Parameters for Enhanced Performance in Low-Permeability Reservoirs

2. Influence of Blade Count and Cutter Density on Drilling Dynamics in Heterogeneous Rock Formations

3. Review of Downhole Vibration Mitigation Techniques in Extended-Reach Drilling Operations

4. Material Science Advancements in Polycrystalline Diamond Compact Tool Manufacturing

5. Hydraulic Optimization Strategies for High-Rate Penetration Drill Bits

6. Field Case Studies on Bit Wear Mechanisms in Abrasive Shale Sequences