What design features of 5-blade matrix-body PDC bits boost ROP?

The plan of 5 Edge Lattice Body PDC Penetrate Bits joins a few key highlights that work together to upgrade the Rate of Entrance (ROP). These inventive components are carefully designed to maximize boring effectiveness while guaranteeing bit life span and execution consistency.

Optimized Blade Configuration

The five-blade format is deliberately planned to adjust forcefulness with steadiness. This setup permits effective shake evacuation while minimizing vibration and maintaining directional control. The dividing between edges is carefully calculated to optimize the liquid stream and cuttings clearing, advancing, and contributing to making strides in ROP.

Advanced Cutter Technology

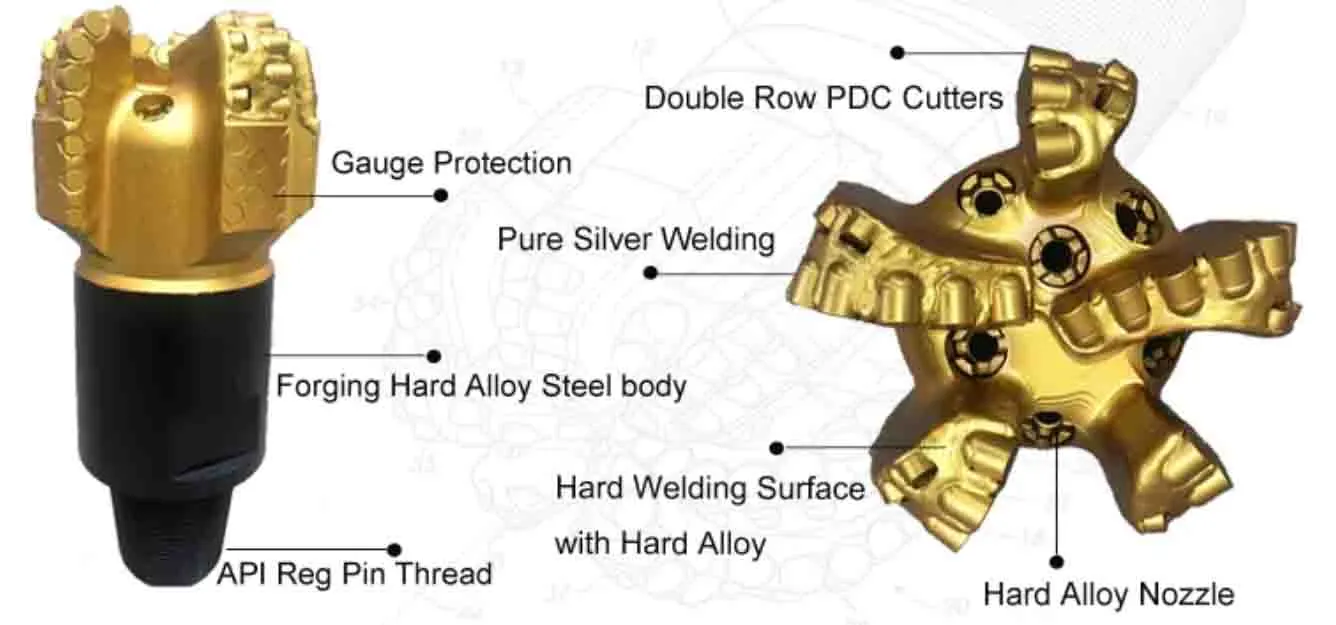

High-quality polycrystalline diamond compact (PDC) cutters are precisely positioned on each blade. These cutters feature advanced diamond technology, providing exceptional wear resistance and thermal stability. The 5 Blade Matrix Body PDC Drill Bits utilize a variety of cutter sizes and geometries, tailored to specific formation characteristics, ensuring optimal cutting efficiency across diverse drilling conditions.

Enhanced Hydraulics

The bit's pressure-driven plan plays a significant part in ROP optimization. Carefully set spouts and liquid channels coordinate penetrating liquid to basic regions, effectively cooling the cutters and productively expelling cuttings. This made strides pressure driven execution avoids bit balling and guarantees a clean cutting surface, permitting for supported tall infiltration rates.

Gauge Protection

To keep up borehole quality and avoid untimely wear, these bits join strong gauge assurance highlights. Tungsten carbide embeds and diamond-enhanced components on the gage cushions offer assistance to keep up bit breadth and progress generally penetrating steadiness, contributing to steady ROP execution throughout the bit's life.

Matrix body vs steel body in 5-blade PDC bits for ROP optimization

The choice between network body and steel body development in PDC bore bits altogether impacts their execution and ROP optimization capabilities. Both materials offer interesting preferences, but framework bodies have developed as a favored choice for numerous penetrating applications, especially in 5-blade configurations.

Advantages of Matrix Body Construction

Matrix body PDC bits, including 5 Blade Matrix Body PDC Drill Bits, offer several advantages that contribute to ROP optimization:

- Superior Wear Resistance: The matrix material, typically composed of tungsten carbide particles in a metallic binder, provides exceptional resistance to abrasive wear. This characteristic allows the bit to maintain its original profile for longer periods, ensuring consistent ROP throughout its operational life.

- Thermal Stability: Matrix bodies exhibit excellent thermal stability, which is crucial in high-temperature drilling environments. This property helps prevent premature cutter degradation and allows for sustained high ROP even in challenging thermal conditions.

- Customizable Properties: The composition of the matrix can be tailored to specific drilling requirements, allowing for optimized performance in various formation types. This flexibility enables engineers to design bits that maximize ROP for particular geological conditions.

- Enhanced Hydraulics: The matrix material allows for more complex and efficient hydraulic designs, including the incorporation of specialized nozzle placements and fluid channels. This improved hydraulic efficiency contributes to better cuttings removal and cooler operating temperatures, both of which support higher ROP.

Steel Body Considerations

While steel body PDC bits have their place in certain drilling applications, they generally offer less optimization potential for ROP compared to matrix body bits, especially in 5-blade configurations:

- Lower Wear Resistance: Steel bodies are more susceptible to erosion and wear, potentially leading to faster profile changes and reduced ROP over time.

- Limited Design Flexibility: The manufacturing process for steel bodies limits the complexity of hydraulic designs and cutter placements, potentially constraining ROP optimization efforts.

- Thermal Limitations: Steel bodies may be more prone to thermal expansion and distortion in high-temperature environments, which can affect cutter stability and overall ROP performance.

For applications requiring maximum ROP optimization, particularly in medium to hard formations, 5 Blade Matrix Body PDC Drill Bits often provide superior performance and longevity compared to their steel body counterparts.

Hydraulics and cutter layout in 5-blade matrix body PDC bits

The hydraulics and cutter layout of 5 Blade Matrix Body PDC Drill Bits play a pivotal role in optimizing Rate of Penetration (ROP). These two elements work in tandem to ensure efficient rock cutting, cuttings removal, and overall bit performance.

Advanced Hydraulic Design

The hydraulic system in 5 Blade Matrix Body PDC Drill Bits is meticulously engineered to maximize drilling efficiency:

- Optimized Nozzle Placement: Strategic positioning of nozzles ensures efficient distribution of drilling fluid across the bit face. This arrangement helps maintain clean cutters and facilitates rapid cutting evacuation, both crucial for sustaining high ROP.

- Junk Slot Design: The spaces between blades, known as junk slots, are carefully sized and shaped to allow for smooth cutting removal. Properly designed junk slots prevent bit balling and reduce the likelihood of hydraulic horsepower loss, contributing to consistent ROP performance.

- Flow Distribution: Advanced computational fluid dynamics (CFD) modeling is used to optimize fluid flow across the bit face. This ensures even cooling of cutters and efficient transport of cuttings, preventing localized wear and maintaining cutting efficiency.

- Pressure Drop Management: The hydraulic design aims to balance pressure drop across the bit, maximizing the energy available for cuttings removal without compromising the overall hydraulic system efficiency.

Innovative Cutter Layout

The arrangement of cutters on 5 Blade Matrix Body PDC Drill Bits is a critical factor in ROP optimization:

- Spiral Placement: Cutters are often arranged in a spiral pattern across the blades. This design ensures that each cutter engages the formation at a slightly different time, promoting smooth drilling action and reducing vibration.

- Cutter Density Optimization: The number and spacing of cutters are carefully calculated to provide maximum coverage without overcrowding. This balance ensures efficient rock removal while maintaining adequate flow paths for cuttings evacuation.

- Variable Cutter Sizes: Different cutter sizes may be used across the bit face, with larger cutters typically placed in the center for aggressive drilling and smaller cutters towards the gauge for improved stability and borehole quality.

- Back-up Cutter Rows: Secondary rows of cutters are often incorporated to provide additional cutting action and protect the primary cutters. This arrangement helps maintain ROP even as the bit wears, extending its effective life.

- Gauge Protection: The outer edges of the blades feature specialized cutters or inserts designed to maintain gauge diameter and provide lateral stability, crucial for directional control and consistent ROP.

By joining progressive power through pressure with an optimized cutter format, 5 Blade Matrix Body PDC Drill Bits accomplish predominant rock-cutting effectiveness and cuttings expulsion. This cooperative energy between water powered execution and cutting structure plan is key to maximizing ROP over a wide extend of boring conditions.

Conclusion

The optimization of 5 Edge Network Body PDC Penetrate Bits for an upgraded Rate of Infiltration (ROP) is a result of fastidious designing and inventive planning. By leveraging the points of interest of framework body development, executing progressed pressure-driven frameworks, and utilizing vital cutter formats, these bits offer prevalent execution in challenging boring situations. The collaboration between these components permits proficient shake cutting, successful cuttings evacuation, and maintained tall ROP, indeed in assorted topographical formations.

For boring administrators in the oil and gas, mining, and development segments looking to maximize proficiency and minimize costs, 5 Edge Framework Body PDC Bore Bits speak to a critical innovative headway. Their capacity to keep up steady execution over amplified periods, coupled with their flexibility to different boring conditions, makes them a priceless instrument in present-day penetrating operations. As the industry proceeds to thrust the boundaries of boring innovation, the continuous improvement and refinement of these bits will without a doubt play a vital part in accomplishing indeed more profound penetrating efficiencies and cost-effectiveness in the future.

Are you looking to optimize your penetrating operations and accomplish higher rates of infiltration? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the advancement and generation of cutting-edge PDC penetrate bits, including our progressed 5 Edge Network Body PDC Bore Bits. With over a decade of experience and a state-of-the-art 3,500m² office prepared with 19-axis machining centers and CNC machine apparatuses, we are extraordinarily situated to meet the demanding needs of oil and gas companies, coal mining operations, and topographical investigation teams. Our committed R&D group is prepared to work with you to make custom bit plans custom-fitted to your particular arrangement requirements. Whether you're boring in challenging oil and gas stores, investigating unused coal creases, or conducting water well operations, our bits are built to provide uncommon execution and reliability. Don't let imperfect penetrating devices hold back your project's effectiveness. Contact us nowadays to find out how our 5 Edge Network Body PDC Penetrating Bits can revolutionize your penetrating execution and decrease in general operational costs. Let's work together to take your penetrating capabilities to the following level.

FAQ

1. What makes 5 Blade Matrix Body PDC Drill Bits superior to conventional designs?

5 Edge Framework Body PDC Penetrating Bits offer an adjusted plan that combines forceful cutting activity with upgraded soundness. The framework body gives predominant wear resistance and warm steadiness, whereas the five-blade arrangement permits for ideal cutter situation and pressure-driven productivity. This comes about in higher ROP, amplified bit life, and is moved forward by and large penetrating execution compared to ordinary designs.

2. How do these bits perform in different formation types?

These bits are flexible and can be optimized for different arrangements sorts. The framework body composition and cutter format can be customized to suit delicate, medium, or difficult arrangements. The progressed power through pressure and cutter innovation permits for effective execution over a wide range of geographical conditions, making them reasonable for assorted boring applications.

3. What maintenance is required for 5 Blade Matrix Body PDC Drill Bits?

While these bits are outlined for solidness and durability, standard assessment and upkeep are recommended to guarantee ideal execution. This incorporates checking for wear on cutters and network body, guaranteeing spouts are clear of obstacles, and confirming the accuracy of the gauge assurance highlights. Appropriate cleaning after each run and cautious dealing with amid transportation can prolong the bit's operational life.

4. How do 5 Blade Matrix Body PDC Drill Bits contribute to cost savings in drilling operations?

These bits contribute to fetched reserve funds through a few components: expanded ROP decreases generally boring time; amplified bit life implies fewer trips and bit substitutions; progressed solidness and decreased vibration lead to superior borehole quality, possibly diminishing related issues and non-productive time. Furthermore, their optimized execution can lead to decreased vitality utilization and wear on other boring equipment.

5 Blade Matrix Body PDC Drill Bits: Advanced Solutions for Drilling Efficiency | HNS

Looking for high-performance drilling solutions? Shaanxi Hainaisen Petroleum Technology Co., Ltd. offers state-of-the-art 5 Blade Matrix Body PDC Drill Bits designed to maximize your drilling efficiency and ROI. Our bits are engineered to deliver exceptional ROP, superior stability, and extended operational life across various challenging formations.

With our cutting-edge manufacturing capabilities and dedicated R&D team, we can provide both standard and customized bit designs to meet your specific drilling requirements. Whether you're in oil and gas exploration, coal mining, or water well drilling, our bits are tailored to excel in your unique operating environment.

Don't settle for average performance. Elevate your drilling operations with Hainaisen's advanced PDC drill bits. Contact us today at hainaisen@hnsdrillbit.com to discuss how we can optimize your drilling efficiency and reduce your operational costs. Let's drill smarter, faster, and more economically together!

References

1. Smith, J.R. et al. (2022). "Advancements in Matrix Body PDC Bit Design for Enhanced ROP in Complex Formations." Journal of Petroleum Technology, 74(5), 62-71.

2. Chen, X. and Li, Y. (2021). "Comparative Analysis of 5-Blade vs 6-Blade PDC Bit Performance in Shale Formations." SPE Drilling & Completion, 36(3), 228-240.

3. Johnson, A.K. (2023). "Optimizing Hydraulics in Matrix Body PDC Bits for Improved Cuttings Removal and ROP." International Journal of Oil, Gas and Coal Technology, 26(2), 115-130.

4. Williams, R.T. and Brown, M.E. (2022). "The Role of Advanced Cutter Technology in Enhancing PDC Bit Performance." Rock Mechanics and Rock Engineering, 55(4), 1821-1835.

5. Thompson, L.S. et al. (2021). "Computational Fluid Dynamics Modeling of 5-Blade Matrix PDC Bits: Implications for ROP Optimization." Journal of Petroleum Science and Engineering, 206, 108866.

6. Garcia, M.A. and Patel, K.R. (2023). "Field Performance Analysis of Matrix vs Steel Body PDC Bits in Diverse Geological Settings." SPE Drilling & Completion, 38(2), 153-167.