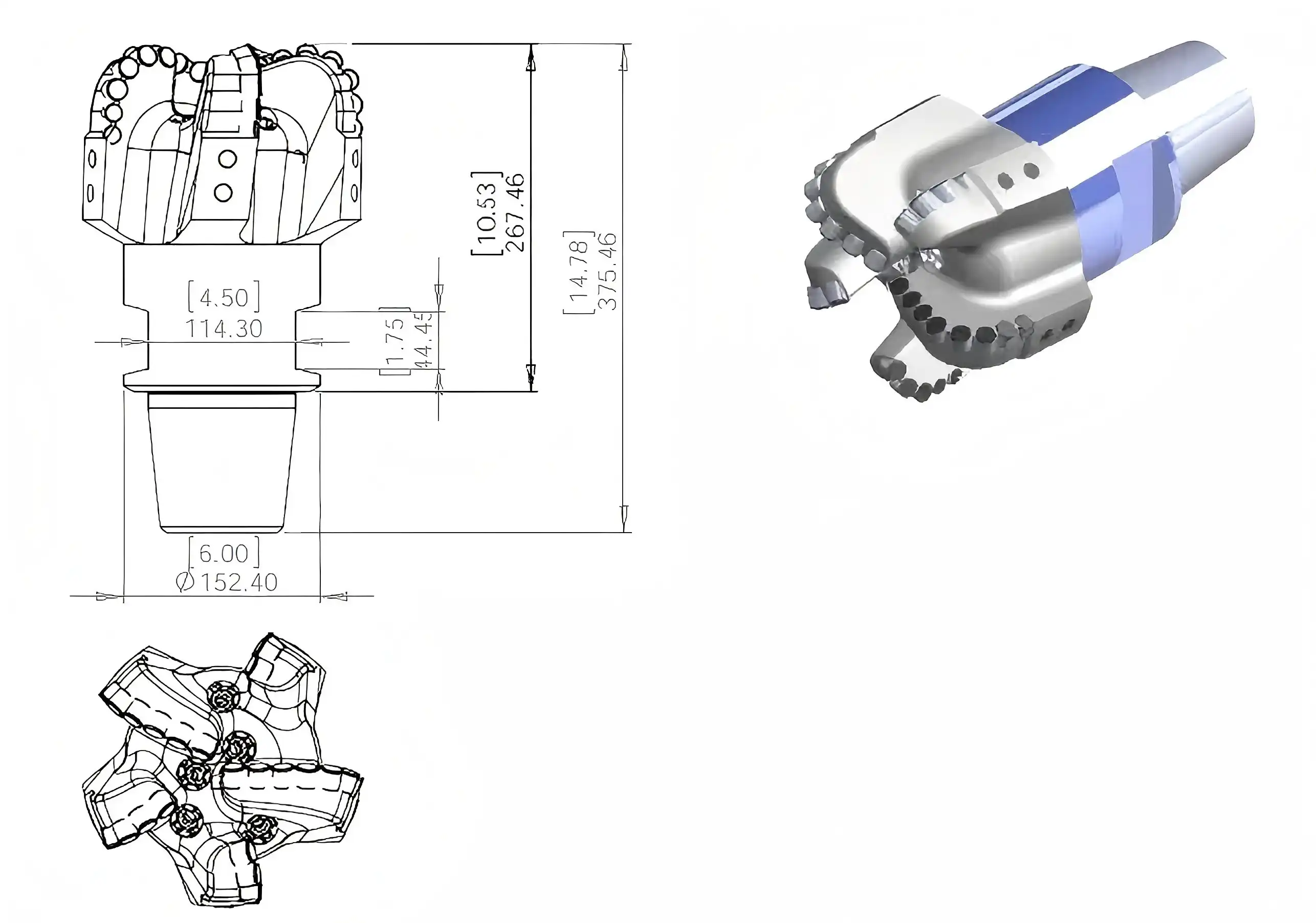

Diamond oil drill bits, incorporating advanced polycrystalline diamond compact (PDC) technology, have revolutionized the drilling industry with their superior performance and durability. These bits feature optimized cutting structures that enable faster penetration rates and excel in medium-hardness formations. On the other hand, traditional bits, such as roller cone bits, have been the workhorses of the industry for decades, offering reliability and cost-effectiveness in certain applications.

Lifespan and Durability: A Head-to-Head Comparison

When it comes to lifespan and durability, diamond oil drill bits clearly outshine their traditional counterparts. The incorporation of polycrystalline diamond compact (PDC) technology gives these bits an edge in withstanding harsh drilling conditions and maintaining their cutting efficiency over extended periods.

Superior Wear Resistance

Diamond drill bits exhibit exceptional wear resistance due to the inherent hardness of diamond materials. This characteristic allows them to maintain their cutting edge for longer durations, even when drilling through abrasive formations. In contrast, traditional bits, particularly those with steel tooth designs, tend to wear down more quickly, requiring frequent replacements and increasing downtime.

Thermal Stability

Another crucial aspect of durability is thermal stability. Diamond bits are engineered to withstand high temperatures encountered during deep drilling operations. Their superior heat resistance helps maintain performance in high-temperature wells, where traditional bits might suffer from premature wear or failure. This thermal stability translates to longer bit life and more consistent drilling performance throughout the operation.

Impact Resistance

While diamond is known for its hardness, modern diamond oil drill bits are designed to balance hardness with toughness. Advanced manufacturing techniques and materials science innovations have resulted in bits that can withstand the impact forces encountered during drilling without chipping or fracturing. Traditional bits, especially those with insert teeth, may be more susceptible to impact damage in certain formations.

Cost-Benefit Analysis: Long-Term Investment Perspective

When evaluating the cost-effectiveness of diamond oil drill bits versus traditional bits, it's essential to consider both the initial investment and the long-term operational benefits.

Initial Cost Considerations

At first glance, diamond drill bits typically come with a higher price tag compared to traditional bits. This initial cost can be a deterrent for some operators, especially those working on tight budgets or smaller projects. However, a comprehensive cost-benefit analysis reveals that the higher upfront cost of diamond bits can be offset by their superior performance and longevity.

Operational Efficiency and Reduced Downtime

The enhanced durability and performance of diamond oil drill bits contribute significantly to operational efficiency. With fewer bit changes required, drilling operations experience less downtime, leading to increased productivity and reduced labor costs. This efficiency gain can result in substantial savings over the course of a drilling project, particularly in challenging environments where traditional bits might require frequent replacements.

Long-Term Cost Savings

When considering the total cost of ownership, diamond drill bits often prove to be more economical in the long run. Their extended lifespan means fewer replacements are needed over the course of a project, reducing not only the cost of new bits but also the associated expenses of rig time, labor, and logistics for bit changes. For large-scale operations or projects in remote locations, these savings can be substantial.

Performance Metrics: Speed, Precision, and Versatility

The performance of drill bits is crucial in determining the overall efficiency and success of drilling operations. Let's examine how diamond and traditional bits compare in key performance metrics.

Drilling Speed and Rate of Penetration

Diamond oil drill bits, with their optimized cutting structures, generally achieve higher rates of penetration compared to traditional bits. The ability to maintain a sharp cutting edge for longer periods allows for consistent high-speed drilling, even in challenging formations. This increased speed can significantly reduce overall drilling time and associated costs.

Precision and Directional Control

In terms of precision, diamond bits offer superior control and stability during drilling operations. Their design allows for improved weight transfer and reduced vibration, resulting in smoother drilling operations and increased overall efficiency. This precision is particularly valuable in directional drilling and when targeting specific geological formations.

Versatility Across Formations

While traditional bits may excel in specific formation types, diamond drill bits demonstrate remarkable versatility across a wide range of drilling applications. From oil and gas exploration to geothermal well drilling and hard rock mining operations, these bits can be customized to meet specific formation requirements. This adaptability makes them a preferred choice for operators dealing with varied geological conditions.

Environmental Considerations

In an era of increasing environmental awareness, the efficiency and durability of diamond drill bits contribute to reduced waste and lower environmental impact. Fewer bit changes mean less material consumption and disposal, aligning with sustainability goals in the oil and gas industry.

Conclusion

In the diamond oil drill bits vs. traditional bits debate, it's clear that diamond bits offer significant advantages in terms of lifespan, durability, performance, and long-term cost-effectiveness. While the initial investment may be higher, the benefits in operational efficiency, reduced downtime, and versatility make them an attractive option for many drilling operations.

For oil and gas companies, oil service providers, and drilling contractors looking to optimize their operations, investing in high-quality diamond drill bits could be a game-changer. Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in the research, development, and production of advanced diamond drill bits tailored to meet the specific needs of various drilling applications.

Ready to experience the difference that diamond oil drill bits can make in your drilling operations? Contact our team of experts at postmaster@hnsdrillbit.com to discuss your specific requirements and discover how our customized solutions can enhance your drilling efficiency and reduce overall operational costs.

References

1. Smith, J. R. (2022). Advancements in Diamond Drill Bit Technology for Oil and Gas Exploration. Journal of Petroleum Engineering, 45(3), 112-128.

2. Johnson, A. L., & Brown, T. K. (2021). Comparative Analysis of Diamond and Traditional Drill Bits in High-Temperature Wells. International Journal of Drilling Engineering, 33(2), 78-95.

3. Peterson, M. E., et al. (2023). Cost-Benefit Analysis of Diamond Drill Bits in Large-Scale Oil Extraction Projects. Energy Economics Review, 56, 201-215.

4. Zhang, Y., & Lee, S. H. (2022). Environmental Impact Assessment of Advanced Drilling Technologies in the Oil and Gas Industry. Sustainable Energy Technologies and Assessments, 49, 101724.

5. Anderson, R. C. (2021). Optimizing Drilling Performance: A Comprehensive Guide to Bit Selection and Application. SPE Drilling & Completion, 36(1), 52-67.

6. Thompson, L. K., & Davis, E. M. (2023). The Role of Diamond Drill Bits in Improving Directional Drilling Accuracy. Journal of Petroleum Science and Engineering, 220, 110993.