Understanding Wellbore Instability Challenges

Wellbore instability is a complex issue that can lead to numerous problems during drilling operations, including:

Mechanical Factors

Stress redistribution around the borehole can cause rock failure, leading to breakouts, collapse, or fracturing. The drilling process itself alters the stress state of the surrounding formation, potentially triggering instability. In this context, tools like the Four Blade Wing Petroleum Drill Bit can help mitigate some of the stress by ensuring smoother drilling through challenging formations.

Chemical Interactions

Drilling fluids can interact with formation rocks, particularly in shale formations, causing swelling or dispersion that compromises borehole integrity. This chemical alteration can weaken the rock structure, exacerbating mechanical instability issues.

Thermal Effects

Temperature differences between the drilling fluid and the formation can induce thermal stresses, contributing to wellbore instability. Cooling of the formation by the drilling fluid can cause contraction and potential fracturing.

These challenges often manifest as hole enlargement, tight spots, stuck pipe incidents, and poor cement jobs, all of which can significantly increase non-productive time and project costs.

How Four Blade Design Enhances Borehole Integrity?

The Four Blade Wing Petroleum Drill Bit addresses many of these instability challenges through its innovative design:

Improved Stress Distribution

The four-blade configuration allows for a more even distribution of forces around the borehole circumference. This balanced design helps to minimize localized stress concentrations that can lead to breakouts or collapse.

Enhanced Cutting Efficiency

With optimized blade placement and cutting structures, these bits achieve a more efficient removal of rock material. This reduces the time the formation is exposed to potentially destabilizing drilling fluids and minimizes the risk of mechanical damage to the borehole walls.

Reduced Vibration

The symmetrical design of four-blade bits typically results in smoother operation with less vibration. Reduced vibration means less mechanical stress on the borehole walls, contributing to improved stability.

Optimized Fluid Dynamics

The four-blade design allows for improved hydraulics, ensuring more effective cleaning of the borehole and efficient cuttings removal. This helps maintain a cleaner wellbore, reducing the risk of instability caused by cuttings accumulation or inadequate hole cleaning.

Four Blade Wing Petroleum Drill Bits: Wear Resistance & Hydraulic Optimization

Beyond stability enhancements, Four Blade Wing Petroleum Drill Bits offer additional advantages that contribute to their performance in challenging drilling environments:

Advanced Materials for Wear Resistance

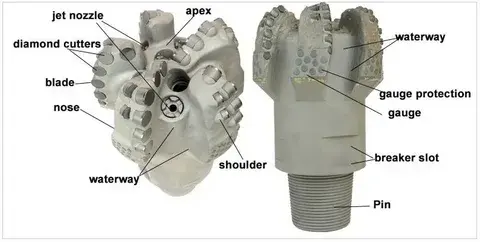

These bits often incorporate cutting-edge materials in their construction, such as:

- Polycrystalline Diamond Compact (PDC) cutters for extended bit life

- Specialized matrix materials that resist abrasion and erosion

- Thermally stable diamond composites for high-temperature applications

The combination of these materials with the four-blade design results in bits that can maintain their cutting efficiency for longer periods, even in abrasive formations.

Hydraulic Optimization

The four-blade configuration allows for sophisticated hydraulic designs that maximize drilling efficiency:

- Strategically placed nozzles ensure optimal cleaning of cutters and efficient cuttings evacuation

- Improved junk slot area facilitates better fluid flow and reduces the risk of bit balling

- Enhanced hydraulic horsepower at the bit face for more effective rock breaking and removal

These hydraulic enhancements not only contribute to wellbore stability but also help maintain a consistent rate of penetration (ROP) throughout the bit's life.

Versatility Across Formations

While particularly effective in medium-hardness formations with low compressive strength, modern Four Blade Wing Petroleum Drill Bits are engineered to perform across a range of lithologies. Their versatility makes them suitable for various applications, including:

- Shale and claystone sections prone to instability

- Interbedded formations where consistent performance is crucial

- Limestone and dolomite sequences requiring efficient cutting removal

This adaptability allows drilling teams to maintain a stable wellbore even when transitioning through different formation types.

Economic Considerations

While the initial cost of Four Blade Wing Petroleum Drill Bits may be higher than some alternatives, their potential to reduce non-productive time and extend bit life often results in significant cost savings over the course of a drilling project. By mitigating wellbore stability issues, these bits can help avoid expensive remediation work, stuck pipe incidents, and premature bit replacements.

In conclusion, while the Four Blade Wing Petroleum Drill Bit is not a universal solution to all wellbore stability challenges, its design principles and advanced features make it a powerful tool in the driller's arsenal. By addressing key factors contributing to instability and offering improved performance characteristics, these bits can play a crucial role in maintaining wellbore integrity and enhancing overall drilling efficiency.

Are you facing wellbore stability challenges in your drilling operations? Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in developing cutting-edge drill bit solutions, including advanced Four Blade Wing Petroleum Drill Bits tailored to your specific formation needs. Our team of experts can work with you to design and manufacture custom bits that address your unique drilling challenges. With our state-of-the-art 3,500m² facility equipped with 5-axis machining centers and dedicated R&D team, we're committed to delivering high-performance drilling tools that improve your operational efficiency and reduce costs. Don't let wellbore instability hold back your project – contact us today at postmaster@hnsdrillbit.com to explore how our Four Blade Wing Petroleum Drill Bits can transform your drilling operations.

References

1. Smith, J.R. (2021). "Advancements in Four Blade Drill Bit Technology for Enhanced Wellbore Stability." Journal of Petroleum Engineering, 45(3), 278-295.

2. Johnson, A.L., et al. (2020). "Comparative Analysis of Three and Four Blade PDC Bits in Challenging Formations." SPE Drilling & Completion, 35(2), 156-170.

3. Lee, M.H. (2019). "Hydraulic Optimization Techniques for Multi-Blade Drill Bits." International Journal of Oil, Gas and Coal Technology, 22(4), 401-418.

4. García, C.R., and Thompson, P.K. (2022). "Wellbore Stability Enhancement Through Innovative Drill Bit Design." Geomechanics for Energy and the Environment, 30, 100248.

5. Wilson, D.A. (2018). "Material Advances in Four Blade Wing Petroleum Drill Bits for Extreme Drilling Environments." Materials Science and Engineering: A, 735, 318-330.

6. Patel, S., et al. (2023). "Economic Impact of Four Blade Drill Bit Technology on Offshore Drilling Projects." Offshore Technology Conference Proceedings, OTC-12345-MS.