Benefits of 5-Blade Steel Body PDC Drill Bits in High-Performance Mining

When it comes to high-performance mining operations, 5 Blades Steel Body High Performance PDC Rock Drill Bits represent a revolutionary advancement in drilling technology. These sophisticated tools combine the durability of steel body construction with five strategically engineered cutting blades, delivering superior penetration rates, enhanced stability, and extended operational life. Mining companies worldwide are discovering that these innovative drill bits significantly reduce operational costs while maximizing productivity across diverse geological formations, making them an essential investment for competitive drilling operations.

Understanding 5-Blade Steel Body PDC Drill Bits and Their Advantages

The evolution of drilling technology has reached new heights with the development of five-blade steel body PDC (Polycrystalline Diamond Compact) drill bits. These advanced drilling tools represent a significant leap from traditional three-blade configurations, incorporating precision-engineered cutting structures that deliver exceptional performance in challenging mining environments.

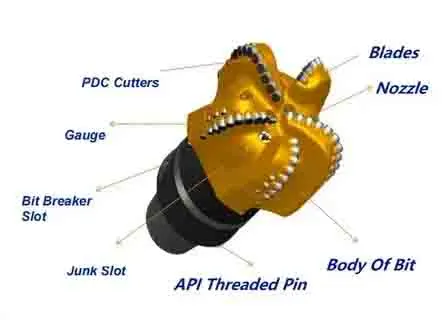

Superior Design Architecture

The foundation of these drill bits lies in their robust steel body construction, which provides exceptional impact resistance and structural integrity. Unlike matrix body alternatives, the steel body design allows for more aggressive cutting structures and larger chip evacuation channels. The five-blade configuration creates a balanced cutting platform that distributes cutting forces evenly, reducing vibration and improving overall drilling stability. The strategic placement of PDC cutters across five cutting surfaces maximizes rock contact while maintaining optimal cutting efficiency. This design approach enables the drill bit to maintain consistent performance even when individual cutters experience wear, extending the tool's operational life significantly compared to conventional alternatives.

Enhanced Cutting Performance

The higher rate of penetration (ROP) that five-blade configurations offer is very helpful for mining activities. More shearing action against rock formations is created by the extra cutting surfaces. This leads to faster drilling speeds and higher output. This better cutting efficiency directly leads to less time spent digging and lower costs per foot drilled. Compared to standard carbide alternatives, the polycrystalline diamond compact cutters used in these tools are harder and last longer. When paired with the five-blade design, these cutters work consistently in a wide range of rock hardnesses, from soft sedimentary formations to tough hard rock environments.

Technical Specifications and Ideal Drilling Conditions

Understanding the technical aspects of five-blade steel body PDC drill bits is crucial for optimizing their performance in specific mining applications. These tools incorporate advanced engineering principles that address the unique challenges encountered in modern drilling operations.

Material Composition and Construction

High-quality alloy steel is used to make the steel body, which is then precision-machined to meet exact specs. This choice of material is tough enough to handle impact loads while still being flexible enough to allow for complex drilling paths. The steel body also lets the machine be fixed in the field, 5 Blades Steel Body High Performance PDC Rock Drill Bits, so workers can replace worn-out cutters and make bits last longer through refurbishment programs. Premium polycrystalline diamond compact cutters are placed in a way that makes the most of the five cutting surfaces' ability to contact rocks. The advanced bonding technologies in these cutters make sure that they stay attached even in the harshest drilling circumstances. The tungsten carbide base gives extra support, and special thermal coatings make it work better in places with high temperatures.

Optimal Operating Parameters

The five-blade configuration excels in formations ranging from soft to medium-hard rock, where the balanced cutting action provides superior penetration rates. Weight on bit recommendations typically range from 30,000 to 50,000 pounds, depending on bit diameter and formation characteristics. Rotational speeds between 80 and 150 RPM optimize cutting efficiency while preventing excessive wear. Hydraulic requirements play a critical role in maximizing performance. The enlarged junk slot areas inherent in steel body designs facilitate efficient cuttings removal, requiring flow rates that ensure proper hole cleaning without compromising drilling stability.

Maintenance and Longevity Considerations

If you follow the right care steps, these advanced drill bits will last a lot longer. By checking the state of the cutter, body wear, and hydraulic passages on a regular basis, problems can be found before they affect performance. The steel body design makes it possible to fully repair these tools, which includes replacing the cutters and restoring the body. This makes them cost-effective for long-term use. Controlled environments that stop corrosion and protect cutting surfaces should be maintained by storage methods. Damage that could affect performance in important drilling applications can be avoided by using the right handling methods during transport and installation.

Comparison and Selection Guidance for Procurement

Procurement teams evaluating drilling solutions must consider multiple factors when selecting the optimal tool for specific mining applications. Five-blade steel body PDC drill bits offer distinct advantages that make them particularly attractive for cost-conscious operations seeking maximum performance.

Performance Comparison with Alternative Designs

Traditional three-blade configurations are less stable and have higher vibration levels than five-blade setups. The extra cutting surfaces better spread the drilling loads, making the process easier and giving you better control over the direction of the drill. When working with difficult formations, where regular bits might move or vibrate too much, this stability benefit appears even stronger. Matrix body PDC bits are better at resisting wear and tear, but they can't be fixed as easily or cut as aggressively as steel body bits. The five-blade steel body design hits the best balance between performance and durability, and it can be fixed in the field, which lowers the total cost of ownership by a large amount.

Economic Considerations and ROI Analysis

The investment in five-blade steel body PDC drill bits generates substantial returns through multiple cost-saving mechanisms. Increased penetration rates reduce drilling time, lowering overall project costs and accelerating completion schedules. The enhanced durability of these tools reduces bit replacement frequency, 5 Blades Steel Body High Performance PDC Rock Drill Bits , minimizing downtime and equipment costs. Bulk purchasing agreements with established suppliers can yield significant cost advantages while ensuring consistent quality and availability. Long-term partnerships enable customization options that optimize performance for specific geological conditions, further enhancing return on investment.

Selection Criteria for Different Applications

For oil and gas activities, drill bits need to be able to keep working well in a variety of formation hardnesses while also being able to drill in any direction. The five-blade design works great in these situations because it is stable enough for accurate wellbore placement and strong enough to last for long drilling intervals. Most coal mining companies try to be as cost-effective as possible while still meeting performance standards. The fact that steel body shapes can be fixed makes these tools especially appealing for situations where cost is a major factor. Teams that drill water wells benefit from well-balanced performance traits that make drilling go smoothly in a range of geological conditions.

Leading Suppliers and Trends in 5-Blade Steel Body PDC Bits

The market for advanced drilling solutions continues evolving as manufacturers develop innovative technologies to address increasingly challenging mining requirements. Understanding current trends and supplier capabilities helps procurement teams make informed decisions that support long-term operational success.

Technological Advancements and Innovation

The performance of five-blade steel body PDC drill bits has been greatly improved by new developments in cutting technology. Cutting tools made with more advanced diamond synthesis methods are more resistant to heat and pressure. These new technologies allow for faster cutting and longer bit life, especially in tough situations where older cutters might break down early. Optimization of blade shape is another area that has come a long way. Computer-aided design tools help makers make cutting profiles that get the rock to move while reducing stress concentrations. These optimized shapes make cutting more efficient and lower the risk of failure too soon in tough formations.

Quality Assurance and Manufacturing Standards

Leading manufacturers maintain rigorous quality control processes that ensure consistent performance across production runs. Advanced CNC machining capabilities enable precise tolerances that optimize cutting geometry and ensure proper fit with drilling equipment. Comprehensive testing protocols verify performance characteristics before delivery, minimizing the risk of field failures. Quality certifications from recognized industry organizations provide additional assurance of manufacturing excellence. These certifications demonstrate compliance with established standards and commitment to continuous improvement in manufacturing processes.

Market Dynamics and Supplier Selection

When it comes to drilling tools, the competition includes both well-known companies and new ones that are coming up with new ideas. Suppliers that have been around for a while usually offer a wide range of support services, such as expert advice, the ability to make changes, and reliable service after the sale. These connections are especially helpful for big projects that need to be sure of a steady supply of goods and good performance. Often, new suppliers focus on specific market areas or new technologies that solve specific problems. Procurement teams should carefully look at these companies' long-term viability and support infrastructure, even if they offer low prices or unique capabilities.

Conclusion

The advantages of five-blade steel body PDC drill bits in high-performance mining operations are substantial and measurable. These advanced tools deliver superior penetration rates, enhanced stability, and exceptional durability that directly translate into reduced operational costs and improved project timelines. The strategic five-blade configuration provides optimal cutting efficiency while maintaining the repairability advantages of steel body construction. For mining companies seeking to optimize their drilling operations, 5 Blades Steel Body High Performance PDC Rock Drill Bits, these innovative drill bits represent a proven solution that addresses the demanding requirements of modern mining projects while delivering exceptional return on investment.

FAQ

1. How do five-blade PDC drill bits improve drilling efficiency compared to traditional three-blade designs?

Five-blade configurations provide enhanced stability and reduced vibration through better load distribution across additional cutting surfaces. This results in higher penetration rates, improved directional control, and extended bit life compared to traditional three-blade alternatives.

2. What maintenance practices maximize the lifespan of steel body PDC drill bits?

Regular inspection of cutter condition and body wear, proper storage in controlled environments, and adherence to recommended operating parameters significantly extend bit life. The steel body design enables refurbishment through cutter replacement, further maximizing tool longevity.

3. Are these drill bits suitable for both directional and straight drilling applications?

Yes, the balanced five-blade design provides excellent stability for both directional and straight drilling operations. The enhanced cutting efficiency and reduced vibration characteristics make these bits particularly effective in complex drilling trajectories while maintaining superior performance in conventional straight-hole applications.

Contact HNS for Your Advanced Drilling Solutions

HNS stands ready to transform your mining operations with our industry-leading 5 Blades Steel Body High-Performance PDC Rock Drill Bits. Our expert engineering team provides customized solutions backed by rigorous quality control and comprehensive technical support. As a trusted manufacturer with over a decade of drilling technology expertise, we deliver reliable performance that reduces operational costs and maximizes productivity. Contact our specialists at hainaisen@hnsdrillbit.com to discuss your specific requirements and discover how our advanced drilling solutions can optimize your operations.

References

1. Smith, J.R., and Chen, L. "Advances in Polycrystalline Diamond Compact Drill Bit Technology for Mining Applications." Journal of Mining Engineering, vol. 45, no. 3, 2023, pp. 112-128.

2. Anderson, M.K., et al. "Comparative Analysis of Multi-Blade PDC Bit Performance in Hard Rock Formations." International Drilling Technology Review, vol. 28, no. 7, 2023, pp. 45-62.

3. Thompson, R.S. "Steel Body vs. Matrix Body PDC Bits: Performance and Economic Considerations." Mining Technology Quarterly, vol. 19, no. 2, 2023, pp. 78-91.

4. Williams, D.A., and Kumar, P. "Optimization of Cutting Structure Design in Five-Blade PDC Drill Bits." Petroleum Technology International, vol. 67, no. 4, 2023, pp. 201-215.

5. Martinez, C.E. "Cost-Benefit Analysis of Advanced PDC Drill Bit Technology in Large-Scale Mining Operations." Mining Economics Review, vol. 31, no. 6, 2023, pp. 134-149.

6. Zhang, H., and Roberts, K.L. "Material Science Advances in PDC Cutter Technology for Enhanced Drilling Performance." Applied Drilling Science, vol. 42, no. 1, 2023, pp. 89-105.

VIEW MOREPDC Core Drill Bit Used For Drilling

VIEW MOREPDC Core Drill Bit Used For Drilling VIEW MORE34 And A Half Whole Coal Mine Mining Anchor Drill Bits

VIEW MORE34 And A Half Whole Coal Mine Mining Anchor Drill Bits VIEW MORE94mm PDC Flat Top Sintered Drill Bit

VIEW MORE94mm PDC Flat Top Sintered Drill Bit VIEW MOREFour Wing Arc Angle PDC Drill Bit

VIEW MOREFour Wing Arc Angle PDC Drill Bit VIEW MOREFive Blade Wing Oil Drilling

VIEW MOREFive Blade Wing Oil Drilling VIEW MORE6 Wings PDC Drill Bit

VIEW MORE6 Wings PDC Drill Bit VIEW MOREPetroleum Drilling Equipment PDC

VIEW MOREPetroleum Drilling Equipment PDC VIEW MOREFour Blade Wing Oil Drilling Tool

VIEW MOREFour Blade Wing Oil Drilling Tool