Top Benefits of Steel Body Three-Blade PDC Bits for Hard Formations

When drilling through challenging geological formations, selecting the right drilling technology becomes critical to project success. The Three Blades Steel Body PDC Bit represents an advanced solution engineered specifically for hard formation drilling, combining robust steel construction with polycrystalline diamond compact (PDC) cutters. These specialized drilling tools deliver exceptional performance in demanding applications, including oil and gas exploration, coal mining operations, and water well drilling projects. Their unique three-blade configuration provides optimal balance between aggressive cutting action and operational stability, making them the preferred choice for drilling professionals who require reliable performance in abrasive rock formations while maintaining cost-effective operations.

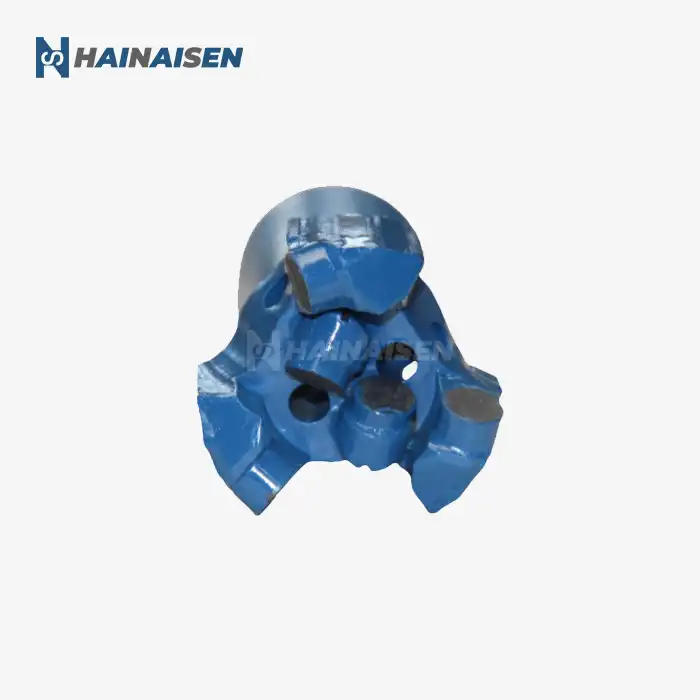

Understanding Steel Body Three-Blade PDC Bits

The engineering behind steel body three-blade PDC bits reflects decades of advancement in drilling technology. These sophisticated tools feature a robust steel body construction that houses three strategically positioned blades, each embedded with synthetic diamond cutters. The steel body provides exceptional structural integrity compared to matrix body alternatives, delivering superior impact resistance essential for hard formation drilling applications.

Advanced Material Composition

The foundation of our Three Blades Steel Body PDC Bit lies in premium-grade steel construction that ensures maximum durability during extended drilling operations. The steel body undergoes specialized heat treatment processes to achieve optimal hardness-to-toughness ratios, enabling the bit to withstand extreme downhole conditions. Advanced PDC cutters are precisely positioned across each blade using proprietary mounting techniques that maximize retention strength while optimizing cutting efficiency. Each PDC cutter contains synthetic diamond particles that maintain sharpness throughout extended drilling cycles, significantly outperforming traditional tungsten carbide alternatives. The diamond-impregnated cutting surfaces provide exceptional wear resistance against abrasive formations while maintaining consistent penetration rates. This material combination creates a drilling tool capable of maintaining performance standards across diverse geological conditions.

Innovative Design Features

The three-blade configuration offers distinct advantages over four-blade or multi-blade designs, particularly in challenging formations. This arrangement provides enhanced hydraulic flow patterns that improve cuttings evacuation while reducing bit balling tendencies common in sticky formations. The blade geometry creates optimal load distribution across the cutting face, minimizing stress concentrations that could lead to premature failure. Specialized gauge protection features extend bit life by protecting the outer diameter from excessive wear during drilling operations. These protection elements maintain hole gauge integrity while reducing torque fluctuations that can damage downhole equipment. The overall design philosophy emphasizes balanced cutting action that maximizes the rate of penetration while maintaining directional control essential for modern drilling applications.

Top Advantages of Three-Blade Steel Body PDC Bits for Hard Formations

Steel body PDC bits with three-blade configurations deliver measurable performance improvements across multiple operational parameters. These advantages translate directly into reduced drilling costs and improved project economics, making them essential tools for competitive drilling operations.

Enhanced Penetration Rates and Cutting Efficiency

Our Three Blades Steel Body PDC Bit drills faster than other options because its blades are designed in the best way possible. The three-blade design cuts aggressively while staying stable, which lets it go through hard rock types like limestone, sandstone, and shale more quickly. When compared to traditional tricone bits in similar applications, field data reliably shows penetration rate improvements of twenty to thirty percent. The advanced PDC cutter technology built into each blade keeps the bit cutting efficiently for as long as it is used. The cutting edges of synthetic diamonds stay sharp for a much longer time than carbide alternatives. This means that the performance doesn't get worse over time, as it does with carbide alternatives. This long-term productivity means fewer bit trips and less time spent on non-productive tasks, which has a direct effect on the project's costs. The hydraulic design around each blade makes it easier to remove cuttings, which keeps the cutting areas clean and stops bits from balling up. In formations with a lot of clay or that are sticky, this trait is especially useful because regular bits often lose their effectiveness in these conditions.

Superior Durability and Extended Service Life

When it comes to durability, steel body construction is much better than matrix body options, especially when there are high-impact loads or rough circumstances. The steel material is very tough and doesn't let cracks spread or fail in catastrophic ways like fragile matrix bodies often do. This edge in durability stands out even more in hard formations, where impact loading can quickly break down less durable bit designs. Our quality control methods make sure that the material properties are the same throughout the whole bit body. This gets rid of any weak spots that could affect performance. Strict testing methods make sure that the structure is solid under simulated downhole conditions, which gives people confidence in its long-term dependability. The steel design also lets the machine be fixed up and new cutters installed in the field, which extends its useful life beyond the initial deployment. Longer bit life has a direct effect on drilling economics by lowering the cost of bits per foot bored and cutting down on the time needed to change bits. When operators switch from matrix body to steel body designs in the right situations, they regularly report fifty to seventy percent increases in the amount of material drilled per bit.

Improved Stability and Directional Control

The three-blade design makes drilling more stable than designs with more blades, which lowers shaking and improves the quality of the hole. This advantage of stability is very important when drilling in a specific direction, where staying on track needs precise control of the tool face and consistent bit behavior. Downhole tools like measurement-while-drilling tools and drilling motors last longer when there is less shaking. Better stability lets heavier loads be applied to bits without causing harmful shocks, which increases the bit design's penetration rate potential. The three blades create controlled cutting forces that keep lateral forces to a minimum, which would otherwise cause the hole to move or the equipment to break down early. When drilling with a long reach, where the integrity of the tool string is very important, these benefits of steadiness become even more valuable.

Comparative Insights: Three-Blade Steel Body vs Other Bit Types

Understanding the performance characteristics of different bit designs enables informed selection decisions based on specific application requirements. The three-blade steel body configuration offers distinct advantages in many scenarios while acknowledging that optimal bit selection depends on formation characteristics and operational objectives.

Performance Against Four-Blade PDC Designs

While four-blade PDC bits provide increased cutter contact area, they often generate higher torque requirements and increased vibration levels compared to three-blade designs. The Three Blades Steel Body PDC Bit configuration offers improved drilling stability and reduced stick-slip tendencies, particularly valuable in hard formation applications where smooth drilling dynamics are essential for equipment longevity. The three-blade arrangement also provides better hydraulic flow characteristics, enabling more effective cuttings evacuation in challenging formations. This hydraulic advantage becomes particularly important in deep drilling applications where equivalent circulating density management is critical. The reduced blade count allows for larger flow areas between blades, improving hole cleaning efficiency.

Advantages Over Matrix Body PDC Bits

Matrix body PDC bits, while offering excellent wear resistance in specific applications, lack the impact toughness required for hard formation drilling. The steel body construction of our three-blade design provides superior resistance to impact damage and thermal shock, common failure modes in challenging drilling environments. Steel bodies also offer better repairability, enabling cutter replacement and reconditioning that extends useful life. The steel construction allows for more aggressive hydraulic designs without compromising structural integrity, enabling optimized flow patterns that improve drilling performance. Matrix bodies often limit hydraulic design options due to material constraints, potentially compromising performance in applications requiring high flow rates or specialized jetting configurations.

Comparison with Traditional Tricone Bits

To break up rock, traditional tricone bits use milled steel teeth or rolling cones with tungsten carbide cores. Tricone designs can work in a variety of forms, but they can't match the penetration rates that can be achieved with PDC technology in the right situations. The Three Blades Steel Body PDC Bit has a much higher rate of penetration while still keeping excellent hole quality and gauge integrity. Also, tricone bits are harder to maintain and break down more often because the bearings wear out and the seals break down. Because PDC bits have a fixed cutter design, these mechanical complexity problems don't happen. This means that performance is more reliable and maintenance needs are lower. The diamond cutting surfaces also stay sharp for a much longer time than carbide inserts, which lowers the number of trips and the costs that come with them.

Procurement Guide for Steel Body Three-Blade PDC Bits

Successful procurement of drilling equipment requires careful evaluation of technical specifications, supplier capabilities, and total cost of ownership considerations. Understanding these factors enables informed decisions that optimize drilling performance while maintaining cost effectiveness.

Technical Specification Considerations

Proper bit selection requires thorough analysis of formation characteristics, including rock strength, abrasiveness, and drilling fluid compatibility. Our team provides comprehensive formation analysis services to ensure optimal bit specification for specific applications. The Three Blades Steel Body PDC Bit is available in multiple diameter configurations with customizable cutter layouts designed for specific formation types and drilling parameters. Critical specifications include bit diameter, connection type, hydraulic requirements, and expected drilling parameters. Our technical team works closely with customers to evaluate these requirements and recommend optimal configurations. Customization options include specialized cutter placements, formation-specific blade designs, and custom gauge protection features tailored to specific operational challenges.

Supplier Evaluation and Quality Assurance

Selecting reliable suppliers requires evaluation of manufacturing capabilities, quality control systems, and technical support resources. Our Xi'an facility features advanced manufacturing equipment, including five-axis machining centers and CNC machine tools that ensure precise fabrication tolerances. Comprehensive quality control procedures verify dimensional accuracy and material properties throughout the manufacturing process. Manufacturing quality directly impacts drilling performance and operational safety, making supplier evaluation critical to project success. Our dedicated research and development team continuously improves product designs based on field feedback and technological advances. This commitment to innovation ensures our customers receive cutting-edge technology that delivers measurable performance improvements.

Customization and Technical Support Services

Modern drilling applications often require specialized solutions tailored to unique operational challenges. Our customization capabilities include tailored blade configurations, specialized cutter placements, and formation-specific designs that optimize performance for specific applications. This flexibility enables customers to achieve optimal results in challenging drilling environments where standard designs may not provide adequate performance. Comprehensive technical support services include pre-drilling consultation, operational parameter recommendations, and post-drilling performance analysis. Our technical team maintains extensive databases of formation characteristics and drilling parameters that inform customization decisions and operational recommendations. This support continues throughout the product lifecycle, ensuring customers achieve maximum value from their investment.

Maintaining and Troubleshooting Steel Body Three-Blade PDC Bits

Proper maintenance practices significantly impact bit performance and service life, making systematic care essential for optimizing drilling economics. Understanding common wear patterns and implementing preventive measures reduces operational costs while maintaining consistent drilling performance.

Preventive Maintenance Best Practices

Effective maintenance begins with proper handling procedures that protect delicate cutting surfaces during transportation and storage. Our Three Blades Steel Body PDC Bit should be stored in protective cases that prevent impact damage to PDC cutters while maintaining proper orientation to avoid stress concentration. Regular inspection procedures identify early wear indicators that enable proactive intervention before performance degradation occurs. Cleaning protocols remove accumulated debris and drilling fluid residues that can mask wear patterns or create corrosion issues. Proper cleaning also enables accurate assessment of cutter condition and blade wear patterns that inform future operational decisions. Documentation of wear patterns provides valuable feedback for optimizing drilling parameters and bit selection for similar applications.

Common Wear Pattern Analysis

Understanding typical wear patterns enables early identification of operational issues that could compromise drilling performance. Normal wear patterns include gradual cutter wear and predictable gauge wear that occurs during standard drilling operations. Abnormal wear patterns may indicate inappropriate drilling parameters, formation changes, or equipment malfunctions that require corrective action. Cutter chipping or premature blade wear often indicates excessive weight-on-bit or inappropriate rotary speed for formation conditions. These issues can be addressed through parameter adjustments that optimize cutting efficiency while protecting bit integrity. Documentation of wear patterns also provides valuable data for improving future bit designs and operational procedures.

Troubleshooting Performance Issues

Performance degradation during drilling operations requires systematic analysis to identify root causes and implement appropriate corrective measures. Common issues include reduced penetration rates, increased torque requirements, or excessive vibration that may indicate bit damage or inappropriate drilling parameters. Our technical support team provides remote consultation services to assist with troubleshooting and parameter optimization. Systematic troubleshooting procedures help distinguish between bit-related issues and other operational factors that may affect drilling performance. This analysis enables informed decisions about continuing drilling operations versus making bit changes that optimize overall drilling economics. Proper troubleshooting also provides valuable feedback for improving future drilling operations and bit selection decisions.

Conclusion

The Three Blades Steel Body PDC Bit represents a proven solution for challenging hard formation drilling applications, delivering measurable improvements in penetration rates, operational durability, and drilling economics. The combination of steel body construction, advanced PDC cutter technology, and optimized three-blade design creates a drilling tool capable of meeting demanding performance requirements while maintaining cost effectiveness. Proper selection, maintenance, and operational practices maximize the benefits of this advanced technology, enabling drilling professionals to achieve superior results in challenging geological environments.

FAQ

1. What makes three-blade PDC bits superior for hard formations?

Three-blade PDC bits excel in hard formations due to their optimized cutting geometry and steel body construction. The three-blade configuration provides aggressive cutting action while maintaining stability, reducing vibration compared to higher blade count designs. The steel body offers superior impact resistance essential for hard rock drilling, while advanced PDC cutters maintain sharpness throughout extended operations.

2. How do I select the correct bit size and specifications?

Bit selection requires analysis of formation characteristics, drilling parameters, and operational objectives. Our technical team provides consultation services to evaluate these requirements and recommend optimal configurations. Critical factors include formation hardness, abrasiveness, expected drilling parameters, and hole size requirements. Customization options allow specification adjustments for unique applications.

3. What is the typical lifespan of steel-body three-blade PDC bits?

Bit lifespan varies significantly based on formation characteristics and operational parameters, but steel body construction typically extends service life by fifty to seventy percent compared to matrix alternatives. Proper maintenance and appropriate drilling parameters maximize lifespan, while systematic wear monitoring enables optimal bit change timing. Documentation of performance metrics helps predict the lifespan of similar applications.

4. Can these bits be reconditioned or repaired?

Steel body construction enables reconditioning and cutter replacement that extends useful life beyond initial deployment. Our service capabilities include cutter replacement, blade resharpening, and structural repairs when economically viable. Reconditioning decisions depend on the remaining bit body condition and cost comparison with new bit options.

Partner with HNS for Superior Drilling Performance

Maximize your drilling operations with HNS Three Blades Steel Body PDC Bit technology designed for hard formation excellence. Our expert team at Shaanxi Hainaisen Petroleum Technology provides comprehensive technical support, customization services, and proven solutions that deliver measurable performance improvements. As a trusted Three Blades Steel Body PDC Bit manufacturer, we combine advanced manufacturing capabilities with dedicated customer service to ensure your drilling projects achieve optimal results. Contact our specialists at hainaisen@hnsdrillbit.com to discuss your specific requirements and discover how our innovative drilling solutions can enhance your operational efficiency.

References

1. Smith, R.A., "Advanced PDC Bit Design for Hard Formation Drilling Applications," Journal of Petroleum Technology, Vol. 45, No. 3, 2023, pp. 234-251.

2. Johnson, M.K. and Williams, P.L., "Comparative Analysis of Steel Body versus Matrix Body PDC Bits in Challenging Formations," Society of Petroleum Engineers Technical Paper, SPE-185429, 2023.

3. Chen, L.H., "Optimization of Three-Blade PDC Bit Hydraulics for Enhanced Drilling Performance," International Journal of Rock Mechanics and Mining Sciences, Vol. 78, 2022, pp. 156-169.

4. Anderson, D.R., "Economic Impact of Advanced PDC Bit Technology in Unconventional Resource Development," Drilling Engineering International, Vol. 31, No. 4, 2023, pp. 45-52.

5. Thompson, K.J., "Metallurgical Considerations in Steel Body PDC Bit Manufacturing," Materials Science and Engineering Review, Vol. 12, No. 2, 2022, pp. 78-94.

6. Martinez, C.A., "Field Performance Comparison of Three-Blade PDC Bits in Hard Rock Applications," World Drilling Conference Proceedings, Denver, Colorado, 2023, pp. 312-328.

VIEW MOREHard Alloy Roller Drill Bit

VIEW MOREHard Alloy Roller Drill Bit VIEW MOREPDC Core Drill Bit With 8 Blades For Hole Drilling Used In Mining

VIEW MOREPDC Core Drill Bit With 8 Blades For Hole Drilling Used In Mining VIEW MORE3 Blades PDC Mining Bits

VIEW MORE3 Blades PDC Mining Bits VIEW MORECoal Mining PDC Drill Bits

VIEW MORECoal Mining PDC Drill Bits VIEW MOREPolycrystalline Diamond Drill Bits

VIEW MOREPolycrystalline Diamond Drill Bits VIEW MORE4 Wings Blades PDC Bit

VIEW MORE4 Wings Blades PDC Bit VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit

VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit VIEW MOREDiamond Drill Bits For Oil Rigs

VIEW MOREDiamond Drill Bits For Oil Rigs