Heat resistance requirements for geothermal bits

Geothermal drilling presents unique challenges due to the high temperatures encountered at depth. The heat resistance of drill bits is a critical factor in their performance and longevity in these extreme environments.

Temperature ranges in geothermal wells

Geothermal wells can reach temperatures exceeding 300°C (572°F) in some cases. These elevated temperatures put tremendous stress on drilling equipment, particularly the drill bits that are in direct contact with the hot rock formations.

Material considerations for three blade oil drill bits in geothermal applications

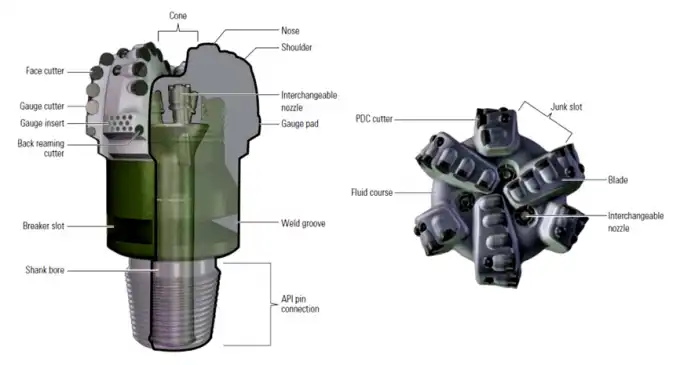

To withstand the intense heat of geothermal drilling, three blade oil drill bits must be constructed using materials with excellent thermal stability. High-strength steel bodies, polycrystalline diamond compact (PDC) cutters, and tungsten carbide matrix materials are commonly used in these bits to provide the necessary heat resistance.

Thermal degradation and its impact on bit performance

As temperatures increment, the hazard of warm debasement to the bit components rises. This can lead to untimely wear, diminished cutting proficiency, and potential disappointment of the bore bit. Producers of three-blade bits for geothermal applications must carefully select materials and plan highlights to moderate these warm impacts and guarantee dependable execution all through the penetrating operation.

Blade erosion in high-thermal-gradient wells

The combination of high temperatures and abrasive formations in geothermal wells can cause accelerated edge wear on a three blade oil drill bit, reducing efficiency and increasing operational challenges. Understanding and tending to this issue is pivotal for keeping up boring productivity and amplifying bit life.

Mechanisms of blade erosion in geothermal environments

In high-thermal-gradient wells, several factors contribute to blade erosion:

- Thermal expansion and contraction of bit materials

- Chemical reactions between bit components and hot formation fluids

- Increased abrasiveness of rock formations at elevated temperatures

- Potential for steam formation and its erosive effects

Strategies to mitigate blade erosion on three blade oil drill bits

To combat blade erosion in geothermal drilling, manufacturers employ various techniques:

- Advanced coating technologies to protect blade surfaces

- Optimized blade geometry to reduce wear and improve fluid flow

- Use of erosion-resistant materials in critical areas of the bit

- Enhanced hydraulics to improve cuttings removal and cooling

Monitoring and managing bit wear during geothermal operations

Effective monitoring of bit wear is essential in geothermal drilling. This may involve:

- Regular bit inspections during trips

- Use of downhole sensors to detect changes in bit performance

- Analysis of drilling parameters to identify signs of excessive wear

- Implementation of wear prediction models specific to geothermal conditions

Comparison with PDC bits in geothermal applications

When considering three blade oil drill bits for geothermal drilling, it's important to compare their performance with other bit types, particularly PDC (polycrystalline diamond compact) bits, which are also commonly used in these applications.

Advantages of three-blade bits in geothermal drilling

Three-blade bits offer several advantages in geothermal environments:

- Improved stability and reduced vibration

- Enhanced durability in medium-hardness formations

- Optimized hydraulics for efficient cuttings removal

- Customizable designs to meet specific formation requirements

- Potential for faster penetration rates in certain geological conditions

PDC bit performance in high-temperature geothermal wells

PDC bits have their own set of advantages in geothermal drilling:

- Excellent wear resistance in abrasive formations

- Ability to maintain sharp cutting edges for extended periods

- High thermal stability of PDC cutters

- Versatility across a wide range of formation types

Selecting the optimal bit type for specific geothermal projects

Choosing between three-blade and PDC bits for geothermal drilling depends on various factors:

- Geological characteristics of the target formation

- Expected temperature profiles in the well

- Drilling objectives (e.g., rate of penetration vs. durability)

- Economic considerations, including bit cost and potential performance gains

- Operator experience and preferences

In many cases, a combination of bit types may be used at different stages of the geothermal drilling process to optimize overall performance and cost-effectiveness.

Conclusion

Three-blade oil drill bits have been demonstrated to be reasonable for numerous geothermal penetrating applications, offering a adjust of execution, stability, and strength. Their progressive plan highlights and customizable alternatives make them an important apparatus in the geothermal driller's arsenal. In any case, the extraordinary conditions experienced in geothermal wells require cautious thought of bit determination, taking into account variables such as thermal resistance, disintegration moderation, and comparative execution with other bit types.

For oil and gas boring companies, oil benefit companies, and other organizations involved in geothermal ventures, choosing the right penetration bit is significant for success. Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the investigation, improvement, and generation of high-quality bore bits planned to meet the interesting challenges of geothermal penetrating. Our progressive fabrication offices and devoted R&D group guarantee that we can give customized arrangements to meet your particular needs.

Whether you're investigating unused geothermal assets, extending existing operations, or looking to optimize your boring execution, our specialists are prepared to help you in selecting the perfect penetration bit for your extend. Contact us nowadays at hainaisen@hnsdrillbit.com to examine how our three-blade oil bore bits and other inventive penetrating arrangements can improve your geothermal boring operations.

References

1. Finger, J., & Blankenship, D. (2010). Handbook of Best Practices for Geothermal Drilling. Sandia National Laboratories.

2. Teodoriu, C., & Cheuffa, C. (2011). A comprehensive review of past and present drilling methods with application to the deep geothermal environment. Proceedings World Geothermal Congress 2010.

3. Thorhallsson, S., & Sveinbjornsson, B. M. (2012). Geothermal drilling technology. Comprehensive Renewable Energy, 7, 277-297.

4. Azar, J. J., & Samuel, G. R. (2007). Drilling engineering. PennWell Books.

5. Lyons, W. C., & Plisga, G. J. (Eds.). (2011). Standard handbook of petroleum and natural gas engineering. Elsevier.

6. Ngugi, P. K. (2008). Geothermal well drilling. Short Course III on Exploration for Geothermal Resources, UNU-GTP and KenGen.