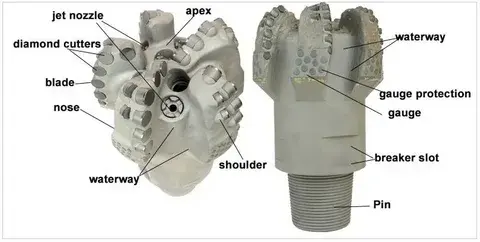

Gauge Pad Configuration for Improved Steerability

The gauge pad configuration plays a crucial role in enhancing the steerability of 6-Blade PDC Drill Bits. By carefully designing the gauge pad layout, manufacturers can optimize the bit's ability to maintain a precise trajectory during directional drilling operations. This is particularly important for medium and large oil service companies that require high levels of accuracy and control in their drilling projects.

Active Gauge Pad Design

An active gauge pad design incorporates specially engineered features that allow for more responsive steering. These may include:

- Spiral stabilizer pads that provide continuous contact with the borehole wall

- Tapered gauge pads that facilitate smoother transitions during directional changes

- Stepped gauge configurations that offer improved stability while maintaining agility

Gauge Pad Material Selection

The choice of materials used in gauge pad construction significantly impacts the bit's performance and longevity. High-wear-resistant materials such as tungsten carbide matrix or diamond-enhanced inserts are often employed to withstand the abrasive conditions encountered during directional drilling. These materials help maintain the gauge pad's shape and effectiveness over extended periods, reducing the need for frequent bit replacements and minimizing downtime.

Cutter Placement Techniques for Reducing Vibration

Vibration reduction is a critical factor in the design of 6-Blade PDC Drill Bits, as excessive vibration can lead to premature wear, reduced drilling efficiency, and potential damage to downhole equipment. Advanced cutter placement techniques are employed to minimize vibration and enhance overall bit performance.

Balanced Cutter Distribution

A balanced distribution of cutters across the six blades is essential for minimizing vibration. This involves:

- Symmetrical placement of cutters to ensure even weight distribution

- Staggered cutter arrangements to break up harmonics and reduce resonance

- Varied cutter sizes and shapes to optimize cutting efficiency across different formations

Anti-Whirl Design

Incorporating anti-whirl features into the cutter placement design helps counteract the tendency for the bit to rotate eccentrically. This can be achieved through:

- Asymmetric blade spacing to disrupt harmonic vibrations

- Strategic placement of depth-of-cut limiters to control aggressive cutting action

- Incorporation of specialized anti-whirl pads or features on select blades

These design elements work together to minimize bit whirl, reducing vibration and improving overall drilling performance across various applications, from oil and gas exploration to geotechnical projects.

Back Rake Angle Optimization for Directional Control

The back rake angle of PDC cutters plays a significant role in determining the directional behavior of the drill bit. Optimizing these angles can greatly enhance the bit's ability to maintain the desired trajectory during directional drilling operations.

Variable Back Rake Angles

Implementing variable back rake angles across the bit face allows for more nuanced control over the drilling direction. This approach involves:

- Utilizing steeper back rake angles on the outer portions of the bit to enhance steerability

- Employing shallower back rake angles in the center of the bit to maintain aggressive cutting action

- Gradually transitioning back rake angles across the bit face to ensure smooth performance

Formation-Specific Optimization

Adapting back rake angles to specific formation characteristics can further enhance directional control and overall drilling performance. This may involve:

- Adjusting back rake angles based on the hardness and abrasiveness of target formations

- Incorporating varied back rake angles within individual blades to handle interbedded formations

- Developing customized back rake configurations for challenging or unique geological conditions

The optimization of back rake angles in 6-Blade PDC Drill Bits represents a crucial aspect of bit design that can significantly impact directional drilling success. By carefully considering formation characteristics and desired trajectory control, manufacturers can create bits that offer exceptional performance across a wide range of applications and geological settings.

Conclusion

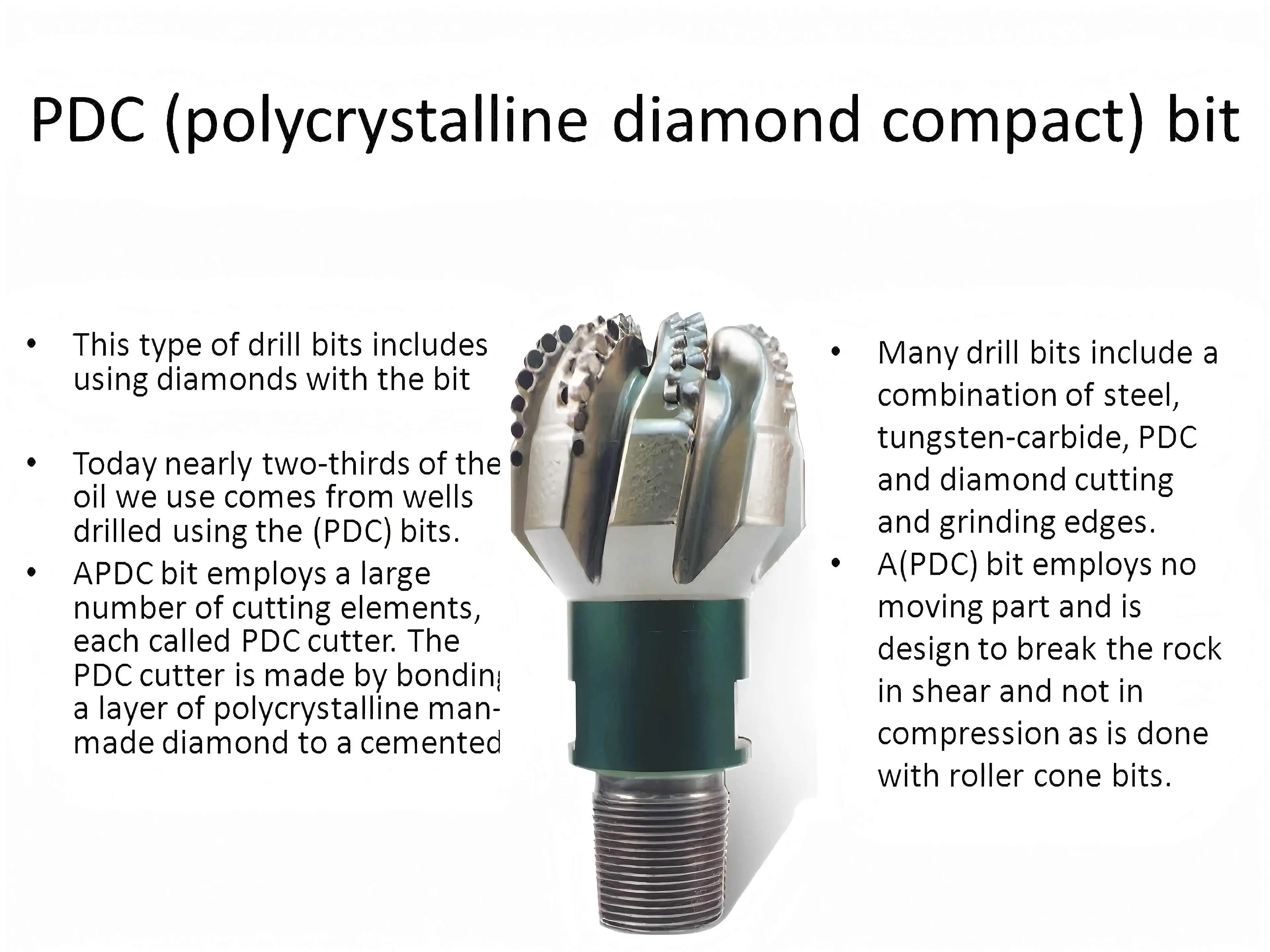

The 6-Blade PDC Bit Design for Directional Drilling represents a significant advancement in drilling technology, offering superior performance and efficiency for a wide range of applications. By incorporating optimized gauge pad configurations, strategic cutter placement techniques, and carefully engineered back rake angles, these bits provide exceptional steerability, reduced vibration, and precise directional control.

For oil and gas drilling companies, coal mining operations, and water well drilling teams seeking to enhance their directional drilling capabilities, the 6-Blade PDC Drill Bit offers a compelling solution. Whether you're tackling challenging formations, require improved efficiency, or need to maintain strict trajectory control, these advanced bits can help you achieve your drilling objectives with greater precision and cost-effectiveness.

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we specialize in the research, development, and production of high-quality PDC drill bits tailored to meet the specific needs of our clients. With our state-of-the-art 3,500m² facility equipped with advanced processing equipment and a dedicated R&D team, we're committed to delivering cutting-edge drilling solutions that drive your projects forward.

Ready to revolutionize your directional drilling operations? Contact our team of experts today to learn more about our 6-Blade PDC Drill Bit offerings and how they can benefit your specific applications. Reach out to us at hainaisen@hnsdrillbit.com to discuss your drilling challenges and discover how our innovative bit designs can help you achieve unprecedented levels of performance and efficiency.

References

1. Smith, J. R., & Johnson, T. M. (2022). Advancements in PDC Bit Design for Directional Drilling Applications. Journal of Petroleum Technology, 74(5), 62-75.

2. Wang, L., & Zhang, Y. (2021). Optimization of Gauge Pad Configurations in PDC Bits for Enhanced Steerability. SPE Drilling & Completion, 36(3), 345-358.

3. Brown, A. K., & Davis, E. L. (2023). Vibration Reduction Techniques in Multi-Blade PDC Bit Designs. International Journal of Rock Mechanics and Mining Sciences, 152, 104982.

4. Lee, S. H., & Kim, H. J. (2022). Back Rake Angle Optimization for Improved Directional Control in PDC Bits. Journal of Petroleum Science and Engineering, 208, 109724.

5. Thompson, R. C., & Wilson, M. A. (2021). Formation-Specific PDC Bit Design: A Case Study in Variable Lithology Environments. SPE/IADC Drilling Conference Proceedings, SPE-204085-MS.

6. Garcia, P. L., & Martinez, F. R. (2023). Advanced Cutter Placement Strategies for 6-Blade PDC Bits in Directional Drilling Applications. Geothermics, 101, 102384.