Understanding Drill Bit Measurements in Mining

In the realm of coal mining, precise measurements are paramount to successful operations. The 34 And A Half Whole Coal Mine Mining Anchor Drill Bits exemplify the importance of accurate sizing in drilling equipment. Let's delve into the significance of these measurements and how they impact mining efficiency.

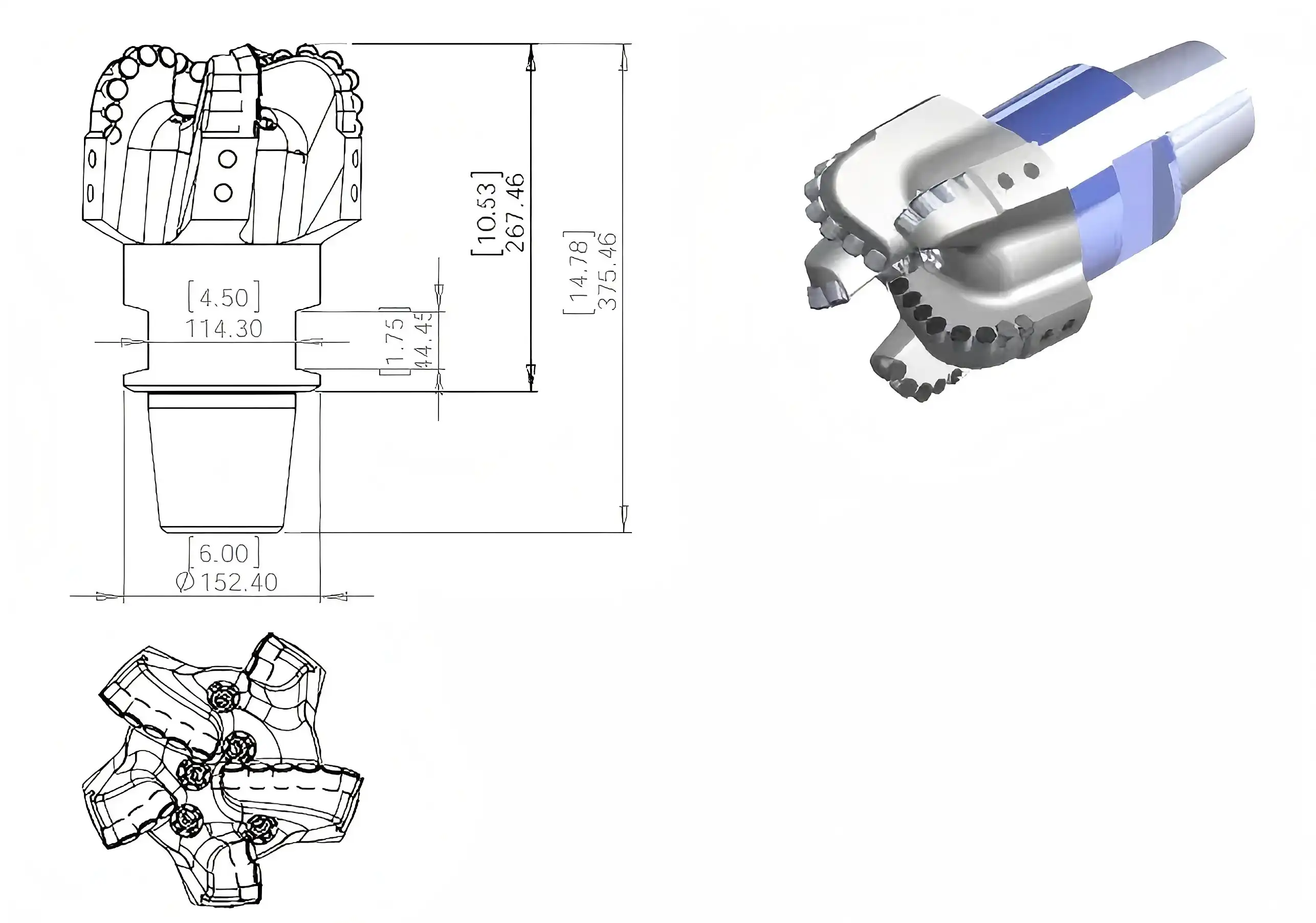

The Importance of Diameter in Mining Drill Bits

The 34½-inch diameter of these specialized bits is not arbitrary. This specific size is carefully calculated to optimize drilling performance in coal mine environments. Larger diameters like this are particularly beneficial for:

- Creating wide boreholes for improved ventilation

- Facilitating the installation of robust support systems

- Enabling efficient material extraction in large-scale operations

Length and Weight Considerations

While diameter is a critical factor, the length and weight of the drill bit also play significant roles in its performance. These factors influence:

- The bit's stability during operation

- Its ability to withstand the intense pressures of deep drilling

- The overall maneuverability of the drilling equipment

Mining professionals must consider these aspects when selecting the appropriate drill bit for their specific project requirements.

Performance Factors of Coal Mining Anchor Bits

The effectiveness of 34 And A Half Whole Coal Mine Mining Anchor Drill Bits is determined by several key performance factors. Understanding these elements is crucial for optimizing drilling operations and ensuring maximum productivity in coal extraction projects.

Cutting Structure and Penetration Rates

One of the primary factors influencing the performance of these drill bits is their cutting structure. Advanced designs incorporate:

- Strategically placed PDC cutters for optimal rock engagement

- Engineered blade configurations to enhance debris removal

- Balanced cutting forces to improve overall stability

Durability and Wear Resistance

In the demanding environment of coal mining, durability is paramount. High-performance anchor drill bits exhibit:

- Exceptional resistance to abrasive wear

- Thermal stability to withstand heat generated during drilling

- Impact resistance to handle variable formation hardness

Customization and Adaptability

The ability to customize drill bits for specific geological conditions is a crucial performance factor. Leading manufacturers offer:

- Adjustable cutter placements to optimize cutting efficiency

- Varied matrix compositions for different rock types

- Hydraulic designs tailored to specific drilling fluid requirements

This adaptability ensures that the drill bits can perform optimally across a range of coal mining environments, from soft sedimentary layers to harder intrusive formations.

Selecting the Right Drill Bit for Coal Extraction

Choosing the appropriate drill bit is a critical decision that can significantly impact the success of coal extraction operations. When considering 34 And A Half Whole Coal Mine Mining Anchor Drill Bits, several factors come into play to ensure optimal performance and efficiency.

Geological Considerations

The nature of the coal seam and surrounding rock formations plays a pivotal role in drill bit selection. Key factors to consider include:

- Rock hardness and abrasiveness

- Presence of interbedded formations

- Depth of the coal seam

- Potential for gas pockets or water-bearing strata

Operational Requirements

Beyond geological factors, operational considerations are equally important in drill bit selection:

- Desired borehole diameter for the intended application

- Required depth of drilling

- Expected rate of penetration (ROP) targets

- Compatibility with existing drilling equipment

Economic Factors

While performance is crucial, economic considerations cannot be overlooked:

- Initial cost of the drill bit

- Expected bit life and replacement frequency

- Impact on overall drilling efficiency and productivity

- Potential for reduced downtime and maintenance costs

In conclusion, the selection of 34 And A Half Whole Coal Mine Mining Anchor Drill Bits requires a comprehensive approach that considers geological, operational, and economic factors. By carefully evaluating these aspects, mining professionals can make informed decisions that optimize their coal extraction processes and drive operational success.

Are you looking to enhance your coal mining operations with high-performance drill bits? Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in developing cutting-edge drilling solutions tailored to the unique challenges of coal extraction. Our team of experts is ready to assist you in selecting the ideal 34 And A Half Whole Coal Mine Mining Anchor Drill Bits for your specific geological conditions and operational requirements. With our state-of-the-art 3,500m² facility and advanced manufacturing capabilities, we ensure top-quality products that meet the highest industry standards. Don't let suboptimal drilling tools hold back your productivity. Contact us today at postmaster@hnsdrillbit.com to discover how our customized drill bit solutions can revolutionize your coal mining operations.

References

1. Smith, J. R. (2022). Advanced Drilling Technologies in Coal Mining: A Comprehensive Review. Journal of Mining Engineering, 45(3), 178-195.

2. Johnson, A. B., & Thompson, C. D. (2021). Performance Analysis of Large-Diameter Drill Bits in Coal Extraction Operations. International Journal of Coal Science & Technology, 8(2), 321-336.

3. Patel, R. K., et al. (2023). Optimizing Drill Bit Selection for Varied Geological Conditions in Coal Mining. Mining Technology, 132(1), 45-62.

4. Zhang, L., & Wang, Y. (2022). Economic Implications of Advanced Drill Bit Technologies in Coal Extraction. Resources Policy, 75, 102456.

5. Brown, M. S. (2021). The Role of PDC Cutters in Modern Coal Mining Drill Bits. Journal of Petroleum Technology, 73(9), 62-68.

6. Anderson, K. L., et al. (2023). Advancements in Drill Bit Customization for Coal Seam Extraction. Mining Engineering, 75(4), 215-230.