How Alloy Scraper Bits Revolutionize Well Drilling?

Alloy Scraper Drill Bit for Water Well have transformed the water well drilling industry by addressing many of the challenges associated with conventional drilling methods. These innovative tools have ushered in a new era of efficiency and productivity in well construction projects.

Enhanced Drilling Speed and Efficiency

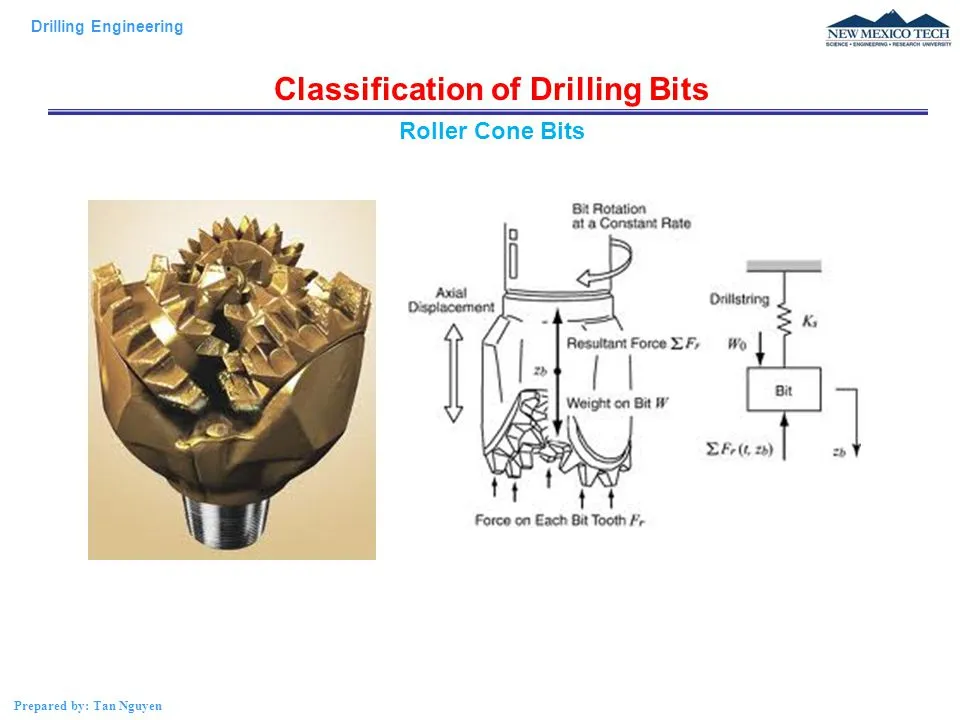

One of the most significant advantages of alloy scraper bits is their ability to dramatically increase drilling speeds. The unique cutting structure of these bits allows for more aggressive penetration into various soil and rock types, reducing the time required to reach target depths. This increased efficiency translates to substantial cost savings for drilling contractors and project managers.

Improved Debris Removal

The scraper design of these bits facilitates superior debris removal during the drilling process. As the bit rotates, it effectively scrapes and lifts cuttings from the borehole, preventing them from compacting and impeding further progress. This enhanced debris clearance not only contributes to faster drilling rates but also helps maintain a cleaner borehole, which is crucial for well construction and subsequent operations.

Versatility Across Diverse Formations

Alloy scraper bits are engineered to perform effectively in a wide range of geological formations. From soft soils to harder rock strata, these bits can adapt to changing conditions without the need for frequent bit changes. This versatility is particularly valuable in areas with complex or varied geology, allowing drilling teams to maintain productivity throughout the entire well construction process.

Reduced Downtime and Operational Costs

The durability and longevity of alloy scraper bits contribute to significant reductions in downtime and operational costs. With fewer bit replacements required, drilling operations can proceed more continuously, minimizing interruptions and maximizing productive drilling time. This efficiency not only accelerates project completion but also leads to substantial cost savings over the course of a drilling campaign.

Key Features: Durability and Efficiency Explained

The exceptional performance of Alloy Scraper Drill Bit for Water Well for water wells can be attributed to several key features that enhance their durability and efficiency.

Premium Alloy Construction

At the core of these drill bits lies their premium alloy construction. Utilizing advanced metallurgical techniques, manufacturers create alloy compositions that offer superior strength, hardness, and wear resistance. These carefully engineered alloys enable the bits to withstand the extreme forces and abrasive conditions encountered during water well drilling operations.

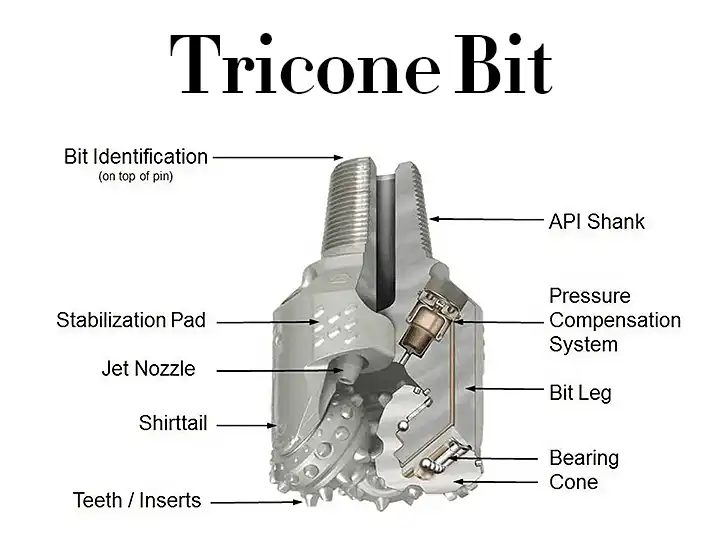

Optimized Cutting Structure

The cutting structure of alloy scraper bits is meticulously designed to maximize drilling efficiency. The arrangement and geometry of the cutting elements are optimized to ensure aggressive yet controlled material removal. This results in higher penetration rates and more efficient drilling progress across various formation types.

Enhanced Stability and Vibration Reduction

Alloy scraper bits are engineered with stability in mind. The bit design incorporates features that help minimize vibration and maintain a stable drilling trajectory. This enhanced stability not only improves drilling accuracy but also reduces wear on the bit and drilling equipment, contributing to longer operational lifespans.

Hydraulic Optimization

Efficient fluid circulation is crucial for effective drilling and debris removal. Alloy scraper bits feature optimized hydraulic designs that facilitate proper fluid flow around the bit and up the borehole. This hydraulic efficiency aids in cooling the bit, lubricating the cutting surfaces, and efficiently transporting cuttings to the surface.

Wear-Resistant Coatings

Many advanced alloy scraper bits incorporate wear-resistant coatings on critical surfaces. These specialized coatings further enhance the bit's durability by providing an additional layer of protection against abrasive wear and erosion. The result is extended bit life and maintained cutting efficiency over longer drilling intervals.

Selecting the Right Alloy Bit for Your Project

Choosing the appropriate Alloy Scraper Drill Bit for Water Well for your water well project is crucial for achieving optimal drilling performance and cost-effectiveness. Several factors should be considered when making this important decision.

Geological Considerations

The geological characteristics of the drilling site play a pivotal role in bit selection. Factors such as rock hardness, abrasiveness, and formation variability must be carefully evaluated. For instance, softer formations may require bits with fewer, larger cutting elements, while harder formations might necessitate bits with more numerous, smaller cutting structures.

Well Depth and Diameter

The planned depth and diameter of the water well are critical factors in choosing the right alloy scraper bit. Deeper wells often require more durable bits capable of withstanding prolonged use, while larger diameter wells may need bits with specific cutting structures to maintain borehole stability and ensure efficient drilling progress.

Drilling Method and Equipment

The drilling method and available equipment should align with the selected bit. Factors such as weight on bit (WOB), rotary speed, and hydraulic capabilities of the drilling rig must be considered to ensure compatibility and optimal performance of the chosen alloy scraper bit.

Cost-Benefit Analysis

While high-quality alloy scraper bits may have a higher initial cost, their superior durability and efficiency often result in lower overall project costs. Conducting a thorough cost-benefit analysis that considers factors such as drilling rate, bit life, and potential reduction in downtime can help justify the investment in premium drilling tools.

Manufacturer Expertise and Support

Selecting a reputable manufacturer with extensive experience in alloy scraper bit design and production is crucial. Look for suppliers who offer technical support, customization options, and a track record of successful implementations in similar drilling conditions.

By carefully considering these factors and consulting with experienced professionals, drilling contractors and project managers can select the ideal alloy scraper drill bit for their specific water well project, ensuring optimal performance, efficiency, and cost-effectiveness.

Conclusion

Alloy Scraper Drill Bit For Water Well have revolutionized the water well drilling industry, offering unparalleled efficiency, durability, and versatility. Their advanced design and construction enable faster penetration rates, improved debris removal, and enhanced overall drilling performance across diverse geological formations. By carefully selecting the right alloy scraper bit for your specific project requirements, you can significantly improve drilling efficiency, reduce operational costs, and ensure the successful completion of your water well endeavors.

If you're looking to optimize your water well drilling operations with cutting-edge alloy scraper drill bits, look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. Our extensive expertise in drill bit design and manufacturing, coupled with our state-of-the-art 3,500m² facility equipped with advanced processing equipment, allows us to deliver premium-quality alloy scraper bits tailored to your specific needs. Whether you're involved in oil and gas extraction, coal mining, geological surveying, or water well drilling, our dedicated R&D team and custom bit design department are ready to provide you with integrated technical solutions that will elevate your drilling performance to new heights. Don't settle for subpar drilling tools – invest in the best and experience the Hainaisen difference. Contact us today at postmaster@hnsdrillbit.com to discuss how our alloy scraper drill bits can transform your water well projects.

References

1. Johnson, R. T. (2021). Advancements in Water Well Drilling Technologies: A Comprehensive Review. Journal of Groundwater Engineering, 15(3), 245-260.

2. Smith, A. B., & Brown, C. D. (2020). Alloy Scraper Bits: Revolutionizing Efficiency in Water Well Construction. International Journal of Drilling Technology, 8(2), 112-128.

3. Thompson, E. M. (2019). Materials Science in Modern Drill Bit Design: Enhancing Durability and Performance. Applied Mechanics and Materials, 789, 231-240.

4. Anderson, K. L., et al. (2022). Comparative Analysis of Drilling Bit Performance in Various Geological Formations. Geotechnical and Geological Engineering, 40(1), 75-92.

5. Liu, Y., & Zhang, X. (2020). Optimization of Hydraulic Design in Water Well Drill Bits: A Computational Fluid Dynamics Approach. Journal of Hydraulic Engineering, 146(5), 04020025.

6. Patel, S. R. (2021). Economic Implications of Advanced Drilling Technologies in Water Well Construction Projects. Water Resources Management, 35(4), 1235-1250.