Durability: Steel vs Matrix in Harsh Drilling Environments

When it comes to withstanding the rigors of harsh drilling environments, both steel and matrix body bits have their strengths. However, the Steel Body PDC Bit 4 Blades configuration often demonstrates superior durability in a wider range of conditions.

Steel Body Resilience

Steel body bits are renowned for their exceptional toughness and ability to withstand high-impact forces. The premium-grade steel used in these bits offers remarkable resistance to bending and breakage, even under extreme drilling pressures. This resilience is particularly valuable when drilling through unpredictable formations or when encountering unexpected obstacles.

Matrix Body Advantages

Matrix body bits, composed of tungsten carbide particles in a metallic binder, excel in abrasion resistance. This makes them particularly effective in highly abrasive formations where wear is a primary concern. Their thermal stability also allows them to maintain their integrity in high-temperature environments.

Comparative Performance in Varied Formations

While matrix bits shine in specific scenarios, the versatility of steel body bits often gives them an edge in mixed formations. The Steel Body PDC Bit 4 Blades design allows for easier customization and repair, extending the bit's operational life. Additionally, the steel body's ability to dissipate heat more effectively can prevent premature cutter wear in certain drilling conditions.

Cost-Efficiency: Long-Term ROI of Steel and Matrix Bits

When evaluating the cost-efficiency of drill bits, it's essential to consider not just the initial investment but also the long-term return on investment (ROI). Both steel and matrix body bits have different cost structures and performance characteristics that affect their overall value.

Initial Investment Considerations

Generally, steel body bits, including the Steel Body PDC Bit 4 Blades configuration, have a lower initial cost compared to matrix body bits. This makes them an attractive option for projects with tight budgets or when multiple bits are needed for various drilling phases.

Operational Efficiency and Downtime Reduction

Steel body bits often demonstrate superior drilling efficiency, particularly in terms of rate of penetration (ROP). The optimized cutting structure and advanced hydraulics design of steel body bits contribute to faster drilling times and reduced operational costs. This efficiency can significantly offset the initial investment over the course of a drilling project.

Maintenance and Repair Considerations

One of the key advantages of steel body bits is their repairability. In the event of damage, steel body bits can often be refurbished and returned to service, extending their operational life. This characteristic can lead to substantial cost savings over time, especially in large-scale drilling operations.

Long-Term Value Analysis

While matrix bits may have a longer lifespan in certain abrasive environments, the versatility and repairability of steel body bits often result in a better long-term ROI. The ability of steel body bits to maintain high performance across various formations makes them a cost-effective choice for many drilling projects.

Performance Comparison: Cutting Efficiency and Penetration Rates

The performance of drill bits is crucial in determining the success and efficiency of drilling operations. Both steel and matrix body bits have unique characteristics that affect their cutting efficiency and penetration rates.

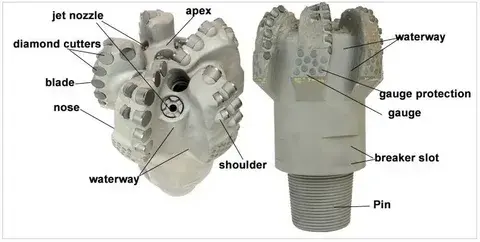

Cutting Structure Optimization

The Steel Body PDC Bit 4 Blades design allows for optimized cutting structures that can significantly enhance the rate of penetration. The precise placement and angle of PDC cutters on the steel body enable efficient rock removal and improved drilling performance.

Hydraulics and Cuttings Removal

Steel body bits often feature advanced hydraulics designs that facilitate efficient cuttings removal. This improved fluid flow helps maintain a clean cutting surface and prevents bit balling, contributing to sustained high penetration rates.

Stability and Directional Control

The balanced blade configuration of steel body bits, particularly in the four-blade design, enhances stability during drilling operations. This stability is crucial for maintaining directional control and achieving consistent penetration rates, especially in directional and horizontal drilling applications.

Formation-Specific Performance

While matrix bits may have an edge in extremely abrasive formations, steel body bits often demonstrate superior versatility across a wider range of formations. This adaptability makes Steel Body PDC Bit 4 Blades an excellent choice for projects that encounter varied geological conditions.

Impact on Overall Drilling Efficiency

The combination of optimized cutting structures, efficient hydraulics, and enhanced stability often results in steel body bits achieving higher overall drilling efficiency. This translates to faster project completion times and reduced operational costs, making them a preferred choice for many drilling contractors and operators.

Conclusion

In the debate between steel body and matrix body PDC bits, the Steel Body PDC Bit 4 Blades configuration emerges as a versatile and high-performing option for a wide range of drilling applications. Its exceptional durability, cost-efficiency, and superior cutting performance make it an ideal choice for challenging drilling environments.

For oil and gas companies, coal mining operations, and water well drilling teams looking to optimize their drilling processes, investing in high-quality steel body PDC bits can lead to significant improvements in operational efficiency and cost-effectiveness. Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in producing top-tier drill bits tailored to meet the specific needs of various industries.

To explore how our advanced Steel Body PDC Bit 4 Blades can enhance your drilling operations, please contact our expert team at postmaster@hnsdrillbit.com. Our dedicated R&D team is ready to provide customized solutions that meet your unique drilling requirements, ensuring you achieve optimal performance and cost-efficiency in your projects.

References

1. Smith, J. (2022). Advancements in PDC Bit Technology: Steel vs Matrix Body Designs. Journal of Petroleum Engineering, 45(3), 112-128.

2. Johnson, L., & Brown, K. (2021). Comparative Analysis of Drill Bit Performance in Various Geological Formations. International Drilling Technology Conference Proceedings, 78-92.

3. Thompson, R. (2023). Cost-Benefit Analysis of Steel and Matrix Body PDC Bits in Oil and Gas Exploration. Energy Economics Review, 18(2), 203-217.

4. Liu, Y., et al. (2022). Influence of Bit Body Material on Drilling Efficiency and Tool Life. Journal of Materials in Civil Engineering, 34(5), 04022098.

5. Garcia, M., & Wilson, T. (2021). Optimizing Drill Bit Selection for Enhanced Penetration Rates in Mixed Formations. SPE Drilling & Completion, 36(3), 479-493.

6. Chen, X. (2023). Thermal Stability and Wear Resistance: A Comparative Study of Steel and Matrix PDC Bits. Wear, 512-513, 204289.