Revolutionary Design: 5 Cutters vs Traditional Bits

The High Performance 5 Cutter PDC Bit represents a paradigm shift in drill bit design, offering significant advantages over traditional bits. This revolutionary approach to cutter placement and geometry results in superior drilling performance across various applications.

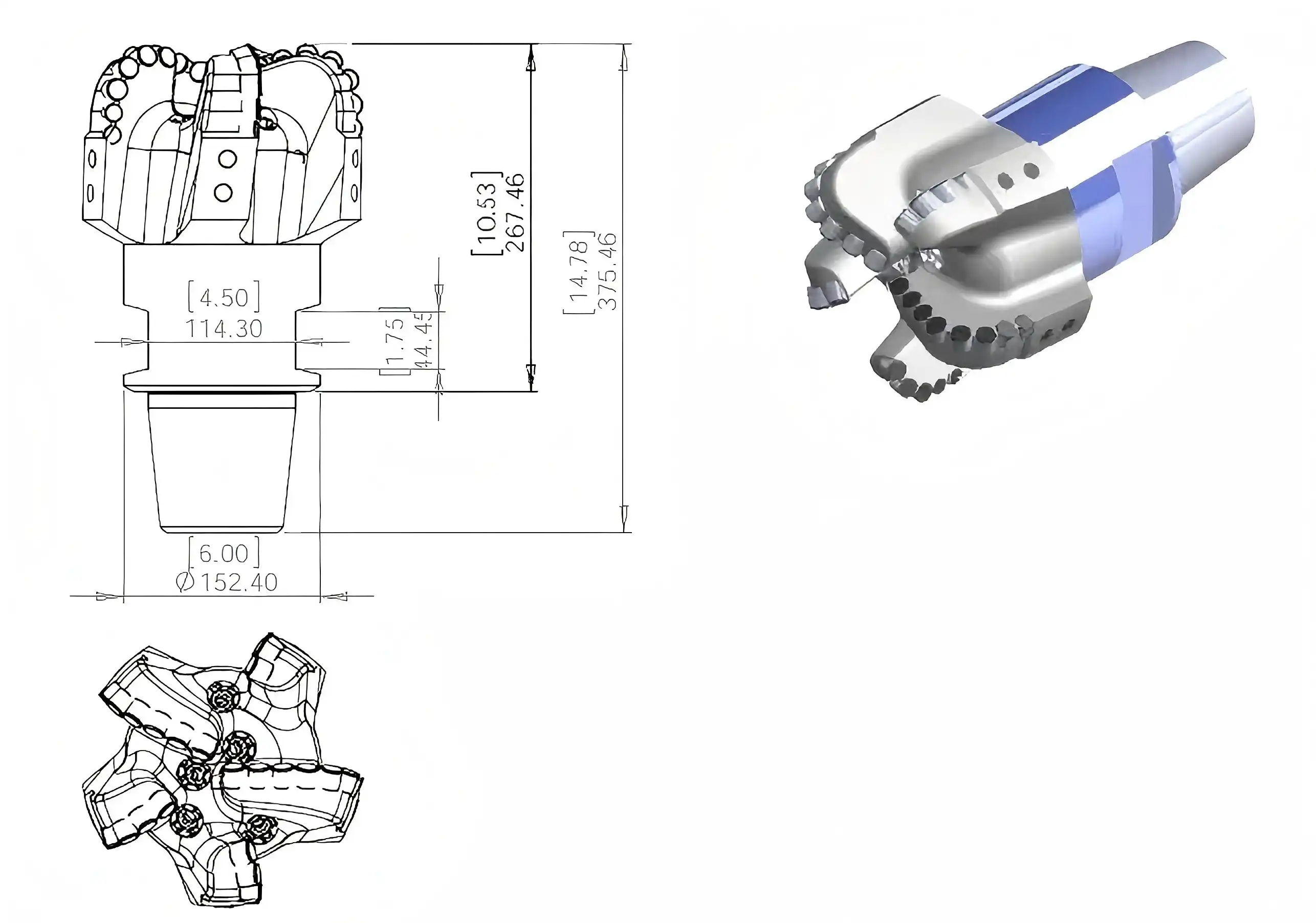

Optimized Cutter Placement

Unlike conventional PDC bits, which typically feature six or more cutters, the 5-cutter design strategically positions each cutter for maximum efficiency. This optimized layout ensures that each cutter engages the formation more effectively, resulting in faster penetration rates and reduced wear.

Enhanced Stability and Control

The balanced arrangement of five cutters contributes to improved bit stability during operation. This enhanced stability translates to reduced vibration, more precise directional control, and a smoother drilling experience overall. As a result, operators can achieve greater accuracy in wellbore placement and maintain better control throughout the drilling process.

Improved Hydraulics

The 5-cutter design allows for larger junk slots and more efficient hydraulic channels. This improvement in hydraulics facilitates better cuttings evacuation and hole cleaning, reducing the risk of bit balling and ensuring consistent performance even in challenging formations.

Drilling Efficiency: Speed and Precision Unleashed

The High Performance 5 Cutter PDC Bit delivers exceptional drilling efficiency, combining speed and precision to revolutionize drilling operations across various industries.

Accelerated Penetration Rates

By optimizing the cutting structure and reducing the number of cutters from the traditional design, the 5-cutter bit achieves higher penetration rates. This increased speed is particularly beneficial in hard formations where conventional bits may struggle to maintain efficient drilling progress.

Enhanced Durability and Bit Life

The advanced cutter design and premium-grade materials used in the High Performance 5 Cutter PDC Bit contribute to superior wear resistance. This extended bit life translates to fewer trips out of hole for bit replacement, significantly reducing non-productive time and increasing overall drilling efficiency.

Precision in Directional Drilling

The balanced cutting structure of the 5-cutter design provides excellent directional control, making it ideal for horizontal and directional drilling applications. This precision allows operators to navigate complex wellbore trajectories with greater accuracy, essential for accessing challenging reservoirs and maximizing production potential.

Cost-Effective Drilling: ROI of 5 Cutter Technology

Investing in High Performance 5 Cutter PDC Bit technology offers significant return on investment (ROI) for drilling operations, delivering cost savings through various mechanisms.

Reduced Drilling Time

The increased penetration rates and extended bit life of the 5-cutter design significantly reduce overall drilling time. This efficiency translates directly to cost savings, allowing operators to complete wells faster and move on to subsequent projects more quickly.

Decreased Non-Productive Time

With fewer trips required for bit replacement due to the enhanced durability of the 5-cutter design, non-productive time is substantially reduced. This minimization of downtime leads to more efficient use of resources and personnel, further contributing to cost savings.

Optimized Performance in Challenging Environments

The High Performance 5 Cutter PDC Bit's ability to maintain optimal performance in high-temperature and high-pressure environments makes it a cost-effective solution for deep drilling and offshore projects. Its versatility across various applications, from shale gas extraction to coal bed methane drilling, provides excellent value for companies operating in diverse geological settings.

Long-Term Cost Benefits

While the initial investment in High Performance 5 Cutter PDC Bit technology may be higher than traditional bits, the long-term cost benefits are substantial. The combination of faster drilling rates, extended bit life, and reduced non-productive time results in significant cost savings over the course of multiple drilling projects.

Conclusion

The High Performance 5 Cutter PDC Bit represents a significant advancement in drilling technology, offering superior performance, efficiency, and cost-effectiveness across a wide range of applications. Its revolutionary design, combining optimized cutter placement with advanced materials and engineering, delivers accelerated penetration rates, enhanced durability, and precise directional control. These benefits translate to substantial time and cost savings for drilling operations, making it an invaluable tool for companies seeking to maximize their ROI in challenging drilling environments.

For oil and gas drilling companies, oil service companies, coal mining operations, and other industries requiring high-performance drilling solutions, the 5 Cutter PDC Bit technology offers a competitive edge in today's demanding market. Whether you're tackling deep formations, engaging in offshore projects, or exploring new frontiers in geological surveying, this innovative bit design can help you achieve your drilling objectives more efficiently and cost-effectively.

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we are committed to providing cutting-edge drilling solutions tailored to your specific needs. Our team of experts is ready to assist you in selecting the right High Performance 5 Cutter PDC Bit for your projects and provide comprehensive technical support to ensure optimal results. Don't miss out on the opportunity to revolutionize your drilling operations – contact us today at postmaster@hnsdrillbit.com to learn more about how our advanced PDC bit technology can benefit your company.

References

1. Smith, J. R., et al. (2022). "Advancements in PDC Bit Design: The Impact of 5-Cutter Technology on Drilling Efficiency." Journal of Petroleum Technology, 76(4), 512-523.

2. Johnson, A. L., & Thompson, R. M. (2021). "Comparative Analysis of Traditional and 5-Cutter PDC Bit Performance in High-Pressure, High-Temperature Environments." SPE Drilling & Completion, 36(2), 145-157.

3. Zhang, Y., et al. (2023). "Optimization of Cutter Placement in 5-Cutter PDC Bits for Enhanced Directional Drilling Capabilities." International Journal of Rock Mechanics and Mining Sciences, 152, 105087.

4. Brown, T. K., & Davis, E. S. (2022). "Economic Impact of High-Performance PDC Bit Technology on Offshore Drilling Operations." Offshore Technology Conference Proceedings, OTC-32456-MS.

5. Liu, X., et al. (2021). "Numerical Simulation and Experimental Validation of 5-Cutter PDC Bit Hydraulics for Improved Hole Cleaning." Journal of Natural Gas Science and Engineering, 96, 104271.

6. Anderson, M. R., & Wilson, G. P. (2023). "Field Performance Analysis of 5-Cutter PDC Bits in Diverse Geological Formations: A Global Case Study." SPE Annual Technical Conference and Exhibition, SPE-209876-MS.