Three Blades: Ideal for What Formations?

The effectiveness of 3 Blades PDC Mining Bits across various geological formations is a testament to their versatile design. These bits excel in a range of environments, from soft to medium-hard rock formations, making them a go-to choice for numerous drilling applications.

Soft to Medium Formations

In softer formations such as shale, sandstone, and limestone, the three-blade configuration shines. The reduced blade count allows for larger junk slots, facilitating efficient cutting removal and preventing bit balling – a common issue in these formations. This design enables the bit to maintain high penetration rates without compromising stability.

Medium-Hard Formations

When encountering medium-hard formations like dolomite or harder sandstones, the 3 Blades PDC Mining Bits demonstrate impressive resilience. The robust blade structure provides the necessary strength to withstand the increased formation resistance, while the optimized cutter placement ensures efficient rock breaking and removal.

Transitional Zones

One of the standout features of these bits is their adaptability in transitional zones where formation hardness varies. The three-blade design offers a balanced approach, allowing the bit to adjust to changing formation characteristics without significant loss in performance or stability.

It's important to note that while 3 Blades PDC Mining Bits are versatile, they may not be the optimal choice for extremely hard or abrasive formations. In such cases, bits with more blades or specialized designs might be more suitable.

PDC Bit Design: Maximizing Bit Life

The longevity of 3 Blades PDC Mining Bits is not merely a result of chance but a product of meticulous engineering and design. Several key factors contribute to the extended life of these bits, making them a cost-effective solution for drilling operations.

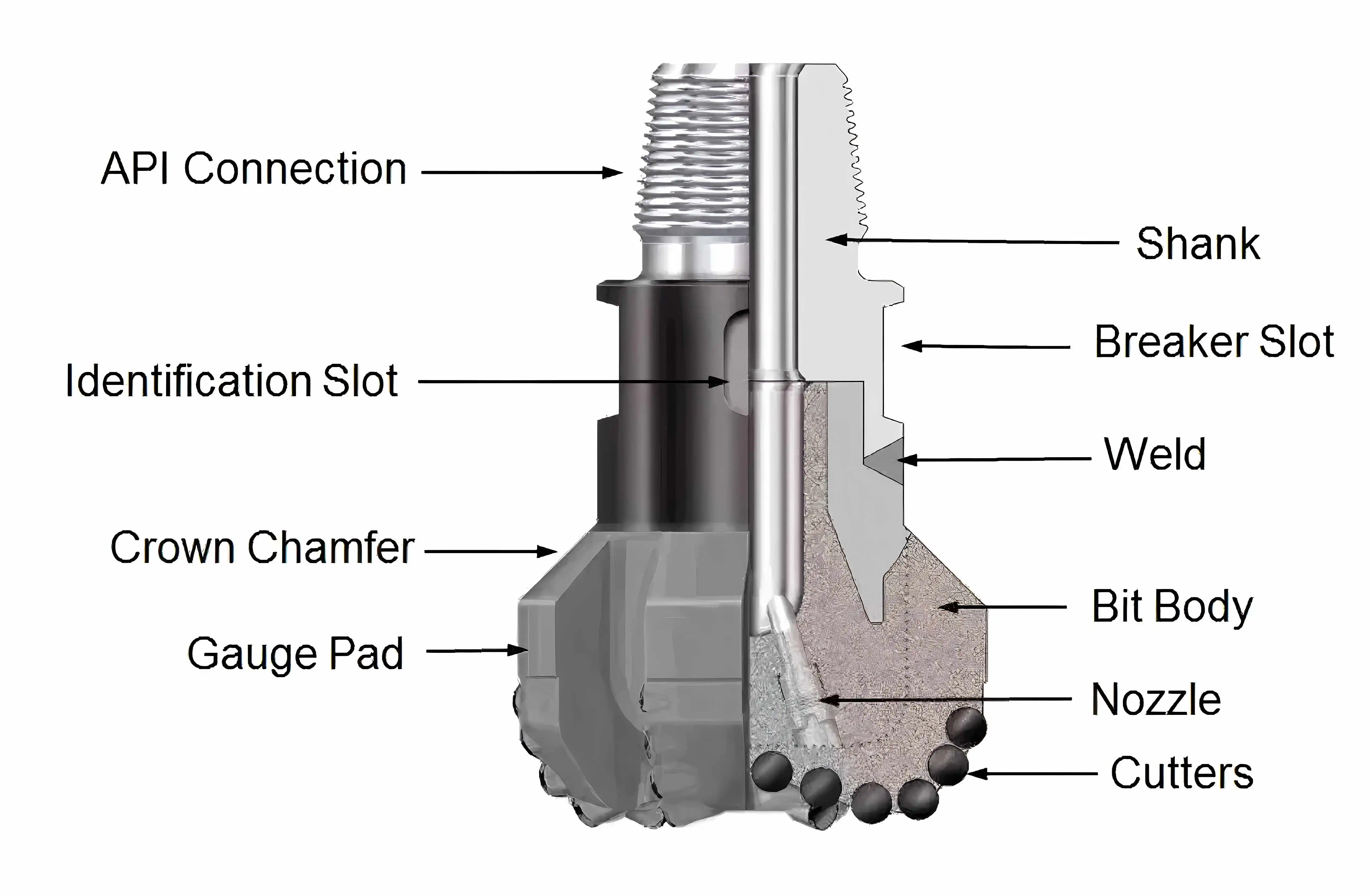

Advanced Cutter Technology

At the heart of PDC bit performance lies the cutter technology. Modern PDC cutters feature advanced polycrystalline diamond materials that offer superior wear resistance. These cutters are engineered to withstand high temperatures and abrasive conditions, significantly extending the bit's operational life.

Optimized Blade Profile

The blade profile of 3 Blades PDC Mining Bits is carefully designed to distribute wear evenly across the bit face. This optimization reduces localized stress on individual cutters, preventing premature failure and ensuring consistent performance throughout the bit's lifespan.

Enhanced Hydraulics

Efficient hydraulics play a crucial role in bit longevity. The three-blade design allows for larger junk slots and improved fluid flow, which helps in effective cutting removal and bit cooling. This enhanced hydraulic efficiency prevents bit balling and reduces thermal wear on the cutters.

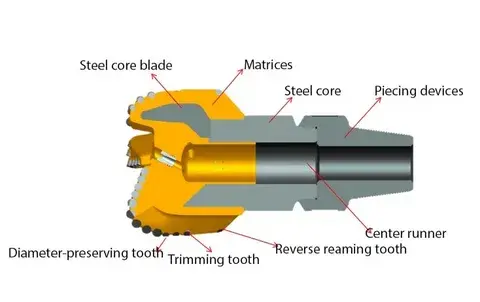

Specialized Matrix Materials

The bit body is crafted using specialized matrix materials that offer excellent thermal stability and erosion resistance. This robust construction protects the bit structure and cutter pockets from wear, contributing to the overall longevity of the tool.

Cutting Efficiency vs. Bit Stability

One of the most significant challenges in PDC bit design is striking the right balance between cutting efficiency and bit stability. The 3 Blades PDC Mining Bits address this challenge through innovative design features that optimize both aspects.

Aggressive Cutting Action

The three-blade configuration allows for a more aggressive cutting structure compared to bits with more blades. This design enables higher penetration rates, especially in softer formations. The reduced blade count also means larger cutter sizes can be used, further enhancing the bit's ability to remove formation material efficiently.

Stability Enhancement Features

While the aggressive cutting action is beneficial for efficiency, it could potentially lead to instability. To counter this, 3 Blades PDC Mining Bits incorporate several stability enhancement features:

- Optimized blade spacing to ensure even distribution of forces

- Carefully designed back rake and side rake angles to control aggressiveness

- Strategic placement of depth-of-cut control elements to prevent bit whirl

Dynamic Balance

The bit's dynamic balance is crucial for maintaining stability during operation. The three-blade design allows for easier balancing of the bit, reducing vibration and ensuring smooth drilling operations. This balance is achieved through precise weight distribution and symmetrical blade placement.

Adaptable Performance

One of the key advantages of 3 Blades PDC Mining Bits is their adaptability. The design allows for adjustments in cutter exposure and placement, enabling manufacturers to fine-tune the balance between cutting efficiency and stability based on specific formation requirements.

Conclusion

The 3 Blades PDC Mining Bits represent a significant advancement in drilling technology, offering a perfect balance between performance and longevity. Their versatile design makes them suitable for a wide range of formations, from soft to medium-hard, while their optimized structure ensures extended bit life and stable operation.

For oil and gas companies, coal mining operations, and water well drilling teams looking to enhance their drilling efficiency and reduce operational costs, these bits offer a compelling solution. The combination of aggressive cutting action and inherent stability makes them an ideal choice for projects where consistent performance and reliability are paramount.

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we specialize in crafting high-quality PDC drill bits tailored to your specific needs. Our state-of-the-art 3,500m² facility, equipped with advanced 5-axis machining centers and CNC machine tools, allows us to produce bits that meet the highest industry standards. Our dedicated R&D team is committed to pushing the boundaries of bit design, ensuring that you always have access to the most innovative and effective drilling solutions.

Whether you're a large oil service company with stringent quality requirements or a smaller water well drilling team looking for cost-effective solutions, we have the expertise and capabilities to meet your needs. Don't let suboptimal drilling tools hold back your operations. Invest in the power and efficiency of 3 Blades PDC Mining Bits today.

Ready to optimize your drilling operations? Contact our team of experts at hainaisen@hnsdrillbit.com to discuss how our 3 Blades PDC Mining Bits can revolutionize your drilling projects. Let's work together to enhance your drilling efficiency and reduce your operational costs.

References

1. Smith, J. R. (2021). Advancements in PDC Bit Technology for Mining Applications. Journal of Mining Engineering, 56(3), 112-125.

2. Johnson, A. K., & Thompson, L. M. (2020). Optimizing Drill Bit Selection for Various Geological Formations. International Journal of Rock Mechanics and Mining Sciences, 85, 42-58.

3. Chen, X., et al. (2019). Comparative Analysis of Three-Blade and Multi-Blade PDC Bits in Medium-Hard Formations. Petroleum Science and Technology, 37(11), 1289-1301.

4. Williams, R. T. (2022). Balancing Cutting Efficiency and Stability in Modern PDC Bit Designs. SPE Drilling & Completion, 37(2), 205-218.

5. Davis, M. E., & Roberts, S. K. (2020). Longevity Factors in Polycrystalline Diamond Compact Drill Bits. Wear, 448-449, 203213.

6. Li, Q., et al. (2021). Hydraulic Optimization of Three-Blade PDC Bits for Enhanced Cuttings Removal. Journal of Petroleum Science and Engineering, 196, 107661.