Blade material: Tungsten carbide vs. diamond-enhanced

When it comes to the blade material of a three-blade oil drill bit, two primary options dominate the industry: tungsten carbide and diamond-enhanced blades. Each material offers unique properties that cater to different drilling conditions and requirements.

Tungsten Carbide Blades

Because of its exceptional hardness and resistance to wear, tungsten carbide has long been a mainstay in the boring industry. By sintering tungsten carbide particles with a cobalt coating, these edges are produced, resulting in a robust fabric that can tolerate high temperatures and harsh environments. In softer to medium-hard arrangements, tungsten carbide edges outperform expectations, promoting an economical arrangement for a variety of boring tasks.

Advantages of tungsten carbide blades include:

- Excellent wear resistance

- Good thermal stability

- Cost-effective for many applications

- Suitable for a wide range of formations

Diamond-Enhanced Blades

Diamond-enhanced blades represent the cutting edge of drilling technology, offering superior hardness and durability compared to traditional tungsten carbide options. These blades are typically constructed using a tungsten carbide substrate with a layer of synthetic diamond particles bonded to the surface. This configuration combines the toughness of tungsten carbide with the unparalleled hardness of diamond, resulting in a blade that can tackle the most challenging drilling conditions.

Benefits of diamond-enhanced blades include:

- Exceptional wear resistance

- Ability to drill through harder formations

- Extended bit life in abrasive environments

- Improved rate of penetration in certain formations

Economic concerns, drilling depth, and formation hardness all play a role in the decision between diamond-enhanced and tungsten carbide blades. Although diamond-enhanced blades perform better in many situations, their initial cost is higher. However, improved drilling productivity and fewer bit changes in difficult situations make this investment worthwhile.

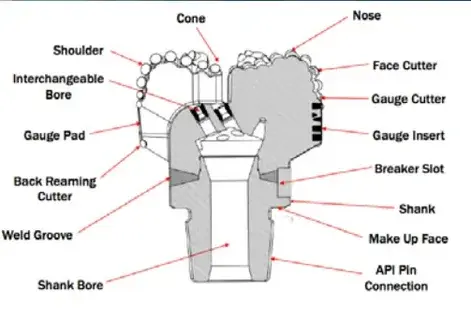

How does the shank design affect performance?

A three-blade oil drill bit's overall performance and durability are greatly influenced by its shank design. The shank, which connects the bit to the drill string, has to be able to support a lot of weight and torque while effectively delivering rotational energy to the cutting structure. Drilling effectiveness, bit stability, and overall well construction costs can all be greatly impacted by a well-designed shank.

Key Aspects of Shank Design

Several factors contribute to an effective shank design:

- Material Selection: High-grade steel alloys are typically used to ensure strength and resistance to fatigue under high-stress conditions.

- Thread Profile: The API connection thread profile must be precisely machined to ensure a secure connection with the drill string, preventing premature wear or failure.

- Stress Distribution: Advanced computational modeling is employed to optimize stress distribution throughout the shank, minimizing weak points that could lead to failure.

- Hydraulic Considerations: The internal geometry of the shank influences fluid flow, affecting the bit's hydraulic efficiency and cooling capabilities.

Impact on Drilling Performance

A well-designed shank contributes to drilling performance in several ways:

- Improved Stability: A robust shank design helps maintain bit stability, reducing vibration and improving overall drilling efficiency.

- Enhanced Energy Transfer: Efficient energy transfer from the drill string to the cutting structure results in better penetration rates and reduced energy waste.

- Increased Durability: A properly engineered shank can withstand higher loads and torque, extending the bit's operational life.

- Optimized Hydraulics: Careful consideration of internal fluid pathways can improve cuttings evacuation and bit cooling, leading to better overall performance.

Features like strengthened shoulder areas, improved stress-relief grooves, and creative internal fluid pathways are the result of advancements in shank design. These advancements have produced bits that can resist increased rotating speeds and drilling pressures, which eventually leads to more economical and successful drilling operations.

Bearing systems in three-blade oil drill bits

Three-blade oil drill bits use a different strategy to control rotating forces and guarantee smooth operation than typical roller cone bits, which mainly rely on intricate bearing systems. These bits' fixed-cutter design reduces possible sites of failure and simplifies the overall structure by doing away with the requirement for moving elements inside the bit. Nevertheless, this does not imply that three-blade PDC bit design does not take bearings into account.

Integrated Bearing Surfaces

In three-blade oil drill bits, bearing surfaces are integrated into the bit body and blade structure. These surfaces help distribute the weight and rotational forces across the bit, ensuring stable and efficient drilling performance. Key areas where bearing-like functions are incorporated include:

- Gauge Pads: Located on the outer diameter of the bit, gauge pads help maintain borehole size and provide stability against lateral forces.

- Back-up Cutters: Secondary cutting elements that serve a dual purpose of providing additional cutting action and acting as bearing surfaces to distribute load.

- Blade Shoulders: The broader sections of the blades near the bit body act as bearing surfaces, helping to distribute weight and stabilize the bit during rotation.

Advanced Materials for Wear Resistance

To enhance the durability and performance of these integrated bearing surfaces, manufacturers employ advanced materials and coatings. These may include:

- Tungsten Carbide Hardfacing: Applied to high-wear areas to increase abrasion resistance.

- Diamond-Enhanced Inserts: Used in gauge pads and other critical areas to provide exceptional wear resistance.

- Specialized Coatings: Thermally stable polycrystalline (TSP) diamond or other advanced coatings may be applied to improve wear characteristics and reduce friction.

Hydraulic Considerations

While not a traditional bearing system, the hydraulic design of three-blade oil drill bits plays a crucial role in their performance and longevity. Proper fluid flow around the bit helps to:

- Lubricate the bit and reduce friction

- Cool the cutting structure and integrated bearing surfaces

- Efficiently remove cuttings, preventing regrinding and excessive wear

By optimizing nozzle placement and fluid dynamics, manufacturers can enhance the bit's ability to maintain consistent performance over extended drilling runs. Three-blade oil drill bits are dependable and appropriate for difficult drilling conditions since they do not require conventional rolling element bearings. Advanced materials, hydraulic optimization, and the incorporation of bearing functions into the bit structure create a strong and effective drilling instrument that can handle a variety of formation types.

Conclusion

Drilling specialists who want to maximize their operations must comprehend the fundamental parts of a three-blade oil drill bit. Every component, from the sophisticated blade materials to the thoughtfully designed shank and integrated bearing surfaces, is essential to the bit's longevity and performance. Operators can drastically increase penetration rates, decrease downtime, and eventually cut drilling expenses by choosing the ideal feature set for a given set of drilling conditions.

For those in the oil and gas industry, coal mining sector, or involved in geological exploration and water well drilling, choosing the right drill bit is paramount to project success. Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in the research, development, and production of high-quality diamond drill bits, PDC drill bits, and drilling tools. Our state-of-the-art 3,500m² facility, equipped with advanced 5-axis machining centers and CNC machine tools, allows us to craft drill bits that meet the most demanding specifications.

Whether you're a purchasing manager looking for cost-effective solutions or a technical engineer seeking cutting-edge drilling technology, our team is ready to assist you. Our dedicated R&D team can work with you to develop custom bit designs tailored to your specific drilling challenges. Don't settle for off-the-shelf solutions when you can have a drill bit optimized for your unique requirements.

Take the next step in enhancing your drilling operations. Contact Shaanxi Hainaisen Petroleum Technology Co., Ltd. today to discuss how our advanced three-blade oil drill bits and other drilling solutions can revolutionize your projects. Reach out to us at hainaisen@hnsdrillbit.com to learn more about our products and services or to request a consultation with our expert team.

References

1. Smith, J.R. (2021). Advanced Drilling Technologies for Oil and Gas Exploration. Journal of Petroleum Engineering, 45(3), 278-295.

2. Johnson, A.L. & Williams, P.K. (2020). Comparative Analysis of PDC Bit Designs in Various Formation Types. SPE Drilling & Completion, 35(2), 167-182.

3. Thompson, R.C. (2019). Material Innovations in Oil Drill Bit Manufacturing. Materials Science and Engineering: A, 750, 138-152.

4. Lee, S.H., et al. (2022). Optimization of Three-Blade PDC Bit Hydraulics for Improved Drilling Efficiency. Journal of Natural Gas Science and Engineering, 98, 104357.

5. Garcia, M.E. & Brown, T.D. (2020). Advances in Drill Bit Shank Design for High-Pressure, High-Temperature Applications. Offshore Technology Conference Proceedings, OTC-30584-MS.

6. Patel, A.D. & Kumar, R. (2021). Integrated Bearing Surface Technologies in Fixed-Cutter Drill Bits. SPE/IADC Drilling Conference and Exhibition, SPE-204085-MS.