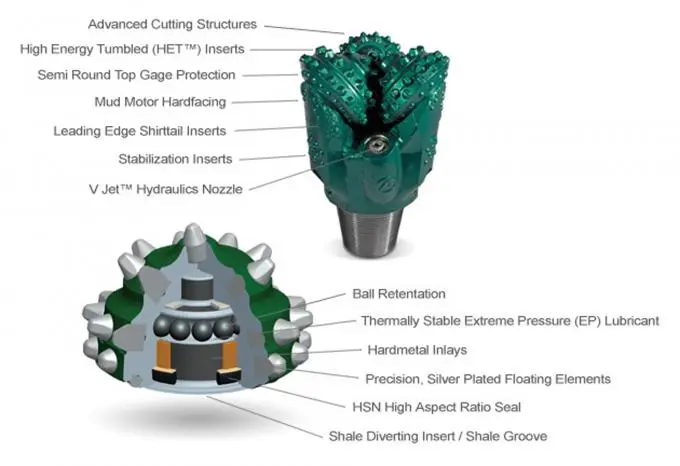

Step-by-step process of making hard alloy drill bits

The creation of high-performance hard alloy scraper drill bits involves a meticulous sequence of operations:

Raw Material Selection and Preparation

The handle commences with the cautious choice of tungsten carbide powders and authoritative materials. These components are accurately measured and blended to accomplish the craved amalgam composition, which straightforwardly impacts the bit's strength and execution characteristics.

Powder Compaction

The blended powders are then compacted into a preform shape using hydraulic presses. This step is crucial in determining the initial density and structural integrity of the drill bit.

Green Machining

At this stage, the compacted preform, known as a "green body," undergoes preliminary shaping. Specialized tools are used to create the basic geometry of the scraper elements and other features of the bit.

Sintering Process

The shaped green body is then subjected to a controlled sintering process. This involves heating the material to temperatures near the melting point of the binder, typically around 1400°C. The sintering consolidates the powder particles, dramatically increasing the density and strength of the alloy.

Infiltration and Bonding

For certain types of hard alloy scraper bits, an infiltration process may be employed. This involves introducing a molten metal, often a copper-based alloy, into the porous structure of the sintered carbide. This step enhances the bit's toughness and thermal conductivity.

Final Machining and Finishing

After sintering and cooling, the drill bit undergoes final machining processes. This may include precision grinding, EDM (Electrical Discharge Machining), or other advanced techniques to refine the cutting edges, fluid channels, and connection threads.

Surface Treatment

To further enhance wear resistance and corrosion protection, the finished bits may receive surface treatments such as nitriding, PVD (Physical Vapor Deposition) coating, or other proprietary processes.

Why sintering is crucial for hard alloy bit strength?

Sintering is a pivotal stage in the manufacture of hard alloy scraper drill bits, playing a fundamental role in determining the final strength and performance of the tool. This process, which involves heating the compacted powder mixture to temperatures just below its melting point, is essential for several reasons:

Particle Bonding and Densification

During sintering, the individual particles of tungsten carbide and binder material fuse together at their contact points. The exact temperature and time parameters of the sintering handle impact grain development, stage dissemination, and the arrangement of a carbide skeleton. This microstructural control is basic for optimizing the adjust between hardness and durability in the last item.

Microstructure Development

Sintering allows for the controlled development of the alloy's microstructure. The exact temperature and time parameters of the sintering prepare impact grain development, stage dissemination, and the arrangement of a carbide skeleton. This microstructural control is fundamental for optimizing the adjust between hardness and durability in the last item.

Homogenization of Properties

The high temperatures involved in sintering promote the uniform distribution of the binder phase throughout the carbide matrix. This homogenization ensures consistent mechanical properties across the entire volume of the drill bit, reducing the risk of localized weak points that could lead to premature failure.

Dimensional Stability

Sintering imparts dimensional stability to the hard alloy scraper drill bit. The controlled shrinkage that happens amid this prepare permits producers to foresee and compensate for measure changes, guaranteeing that the last item meets exact dimensional details basic for penetrating precision.

Quality control in hard alloy scraper bit production

Guaranteeing the most noteworthy quality guidelines in the generation of difficult amalgam scrubber bore bits is foremost for assembly the requesting necessities of the penetrating industry. Thorough quality control measures are actualized all through the fabricating prepare to ensure the unwavering quality, execution, and security of these basic boring components.

Raw Material Inspection

Quality control begins with the thorough inspection and testing of incoming raw materials. Progressed procedures such as X-ray diffraction and molecule estimate investigation are utilized to confirm the composition and characteristics of tungsten carbide powders and cover materials. This initial scrutiny is crucial for maintaining consistency in the final product's properties.

Process Monitoring and Control

Throughout the manufacturing stages, from powder mixing to sintering, sophisticated monitoring systems are utilized to ensure adherence to precise specifications. Parameters such as temperature profiles, pressure levels, and atmospheric conditions are continuously tracked and adjusted to maintain optimal production conditions.

Non-Destructive Testing

After production, each hard alloy scraper drill bit undergoes a series of non-destructive tests to verify its structural integrity. These may include:

- Ultrasonic inspection to detect internal flaws or discontinuities

- X-ray radiography to examine the internal structure and identify any voids or inclusions

- Magnetic particle testing to check for surface or near-surface defects

Dimensional Verification

Precision measurement tools, including coordinate measuring machines (CMMs) and laser scanning systems, are employed to ensure that every drill bit meets the exact dimensional specifications required for optimal performance and compatibility with drilling equipment.

Performance Testing

Selected samples from each production batch undergo rigorous performance testing. This may involve simulated drilling operations under controlled conditions to evaluate factors such as wear resistance, cutting efficiency, and thermal stability. Such tests provide valuable data for continuous improvement of the manufacturing process.

Material Analysis

Periodic metallographic analysis is conducted on finished bits to examine the microstructure, grain size, and phase distribution of the hard alloy material. This point by point examination makes a difference in keeping up the ideal adjust between hardness and durability required for prevalent penetrating execution.

Documentation and Traceability

Comprehensive documentation is maintained throughout the production process, ensuring full traceability of each drill bit from raw material to finished product. This fastidious record-keeping is fundamental for quality confirmation and encourages nonstop handle improvement. By actualizing these rigid quality control measures, producers can guarantee that each difficult amalgam scrubber penetrate bit meets the demanding guidelines requested by the boring industry, giving dependable execution in the most challenging operational situations.

Conclusion

The manufacture of hard alloy scraper drill bits is a sophisticated process that combines advanced materials science with precision engineering. From the careful selection of raw materials to the final quality control checks, each step is critical in producing tools that can withstand the extreme conditions encountered in drilling operations. The sintering process, in particular, plays a pivotal role in developing the exceptional strength and durability that characterize these high-performance bits.

For drilling professionals seeking top-tier hard alloy scraper drill bits that deliver unparalleled performance and reliability, look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. Our state-of-the-art 3,500m² facility, equipped with advanced 7-axis machining centers and CNC machine tools, enables us to produce drill bits of the highest quality. Our dedicated R&D team specializes in custom bit designs to meet the unique needs of various drilling applications, from oil and gas extraction to coal mining and geological surveying.

Experience the difference that precision-engineered hard alloy scraper drill bits can make in your drilling operations. Contact us today at hainaisen@hnsdrillbit.com to discuss your specific requirements and discover how our products can enhance your drilling efficiency and productivity.

References

1. Johnson, R. T. (2021). Advanced Manufacturing Techniques for Hard Alloy Drilling Tools. Journal of Materials Engineering and Performance, 30(8), 5672-5685.

2. Smith, A. B., & Brown, C. D. (2020). Sintering Processes in Tungsten Carbide-based Alloys: A Comprehensive Review. International Journal of Refractory Metals and Hard Materials, 92, 105277.

3. Lee, H. S., et al. (2019). Quality Control Strategies in the Production of High-Performance Drilling Components. Materials Today: Proceedings, 12, 384-391.

4. Zhang, Y., & Wang, L. (2022). Innovations in Hard Alloy Compositions for Extreme Drilling Environments. Wear, 488-489, 204161.

5. Thompson, K. L. (2020). Microstructural Evolution During Sintering of Tungsten Carbide-Cobalt Alloys. Metallurgical and Materials Transactions A, 51(7), 3421-3435.

6. Garcia, M. E., et al. (2021). Advanced Surface Treatments for Enhanced Durability of Hard Alloy Drilling Tools. Surface and Coatings Technology, 409, 126907.