What Drilling Conditions Favor a 5 Blades PDC Oil Bit?

A 5 Blades PDC Oil Bit works best in medium to hard rock layers with low to middling compressive strength. These rock types include gypsum, shale, limestone, and sandstone. When controlled drilling conditions like 60–250 RPM rotating speeds, 30–180 KN drilling pressure, and 45–80 LPS flow rates are used, these bits work very well. The five-blade design strikes a perfect balance between cutting speed and operating stability. This makes it perfect for directional drilling, horizontal wells, and rocks that need steady penetration rates with little vibration.

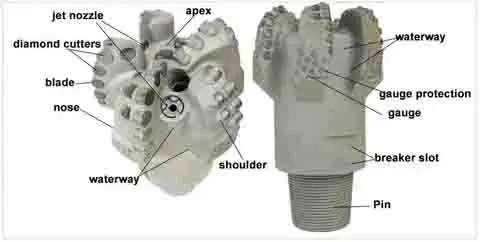

Understanding the Technical Features of 5 Blades PDC Oil Bits

A 5 Blades PDC Oil Bit is a great piece of engineering because it was carefully designed to balance a lot of different performance factors. As a strategic matter, this arrangement strikes a balance between the cutting power of three-blade designs and the durability of seven-blade designs.

Blade Configuration and Cutter Distribution

The five-blade design makes the best space for strategically placing the cutters while still leaving enough junk slot areas for effective debris removal. Each blade has carefully placed polycrystalline diamond compact cutters that work together to break up rocks in a uniform way. The shape of the blade includes certain rake angles and direction patterns that keep vibrations to a minimum while still cutting very well.

The modern PDC cutters in these bits use advanced diamond synthesis technology to make cutting surfaces that are very hard and stay sharp during long drilling operations. The tungsten carbide matrix that supports these tools gives them the impact strength they need to work with different formation hardness levels without breaking too soon.

Hydraulic Flow Optimization

A bit's efficiency depends on how well its hydraulics are designed. The five-blade design lets for carefully planned junk holes that make it easier for drilling fluid to flow. These flow lines make sure that the cutting elements stay cool enough while moving rock chips quickly to the top.

The shape of the bit face includes specific flow patterns that move the drilling mud across all cutting surfaces. This keeps the diamond cutters from getting too hot, which could damage them. This hydraulic efficiency has a direct effect on both the rate of entry and the life of the bit in difficult drilling conditions.

Ideal Drilling Conditions Favoring 5 Blades PDC Oil Bits

Knowing the best place for these specialized drilling tools to work lets buying pros make smart choices that get the best return on investment. The performance of 5 Blades PDC Oil Bits is best when they are used in certain physical and tactical situations.

Formation Characteristics and Rock Properties

When working in sedimentary rock with a medium amount of stiffness, five-blade PDC bits work very well. The balanced cutting action these bits provide works well on shale rocks, especially those found in unconventional oil and gas production. The steady contact of the cutter helps keep the drilling paths fixed, which is important for developing horizontal wells.

Five-blade designs are good for limestone rocks with middling compressive strength because they are aggressive in a controlled way. The bit keeps its entry rates steady without shaking too much, which can happen with more aggressive designs in these situations. The five blades' balanced cutting forces make it easier to work with sandstone forms, especially those that have layers of different stiffness that are layered on top of each other.

5 Blades PDC Oil Bits work well with gypsum and other evaporite rocks because they pose their own difficulties. The perfect distance between the blades stops bit balling and keeps up enough cutting action to reach the desired penetration rates.

Optimal Operating Parameters

To get the best results, you need to pay close attention to the drilling factors. Rotary speeds between 60 and 250 RPM are just right for getting the job done quickly and protecting the cutter. When the rock is hard, lower speeds work best. When the rock is soft, higher speeds can be used if the rock's properties allow it.

The recommended weight for a bit is usually between 30 and 180 KN, but the exact number will depend on the hardness of the formation and the drilling goals. When the weight is evenly distributed across the five blades, there is even wear, and the bit lasts a lot longer than when it is poorly loaded.

Hydraulic flow rates between 45 and 80 liters per second are enough to clean the hole while keeping the bottomhole pressure under control. These flow rates make sure that the cuttings are removed effectively without causing corrosion problems that could hurt the bit's performance.

Environmental Adaptability

In today's drilling settings, you need tools that can handle complicated conditions downhole. 5 Blades PDC Oil Bits work great for both directional and horizontal drilling jobs where it's important to keep the wellbore shape accurate. The adjusted cutting forces make it less likely for the bit to walk, which makes it easier to control the direction of travel on difficult paths.

The heating properties of PDC cuts make it easy to deal with changes in temperature that happen during deeper drilling. The diamond-carbide interface stays strong at a lot of different temperatures, so the performance is the same from the top to the bottom.

Comparing 5 Blades PDC Oil Bits with Other Drill Bits

There are many types of bits used in the drilling business, and each one is designed for a particular job and type of rock. Knowing these differences helps buying teams choose the drilling problem-solving option that will save them the most money.

Performance Against Three-Blade Variants

Because there is more weight on each blade, three-blade PDC bits usually cut more aggressively. This makes them good for soft forms where fast entry is important. But this aggression often comes at the cost of stability, especially in heterogeneous layers where different rock qualities can make drilling behave in strange ways.

5 Blades PDC Oil Bit designs let you handle the cutting action better by spreading the force over more touch points. This spread makes drilling smoother and less noisy, which improves control of the tool face in directional uses and makes the wellbore quality better overall.

Advantages Over Seven-Blade Designs

Even though seven-blade PDC bits are the most stable, they often have lower penetration rates because each cutter has to work with a larger area of metal. The extra blades can also slow down the fluid flow, which could make it harder to remove the cuttings in some situations.

5 Blades PDC Oil Bit designs are the best because they hit the perfect mix between being stable enough for most uses and having the cutting power needed for competitive penetration rates. The fewer blades compared to models with seven blades make the junk holes bigger, and the hydraulics work better.

Comparison with Roller Cone Technology

In rocks that are very hard or rough, where PDC technology has problems, traditional tri-cone bits can still be used. However, 5 Blades PDC Oil Bits work best in medium-hardness forms. The fixed-blade design, on the other hand, has several benefits, such as higher penetration rates, longer bit life, and lower upkeep needs.

Because PDC designs don't have any moving parts, they don't have to deal with bearing problems that can happen with roller cone bits during long drilling operations. This advantage in dependability is especially useful when digging underwater or in remote areas, where bit trips cost a lot of money.

Maintenance, Troubleshooting, and Usage Tips for 5 Blades PDC Oil Bits

Paying attention to the right ways to handle, operate, and maintain PDC drilling technology is important for getting the most out of your investment. Knowing the most common ways bits break and how to stop them from happening can help them last longer and keep drilling at its best.

Preventive Maintenance Protocols

Before the bit even gets to the drill floor, it should be inspected regularly. By looking at the state of the cutter, the integrity of the blades, and the hydraulic tubes, problems can be found before they affect drilling activities. Putting things away in the right protective cases keeps them from getting damaged during movement and handling on the rig floor.

Monitoring the drilling parameters is a very important part of regular maintenance. Trends in force, weight on bit, and puncture rate can be seen in real time and can show problems before they cause the bit to break. When torque suddenly goes up or down, it's usually a sign that the parameters need to be changed or the bit needs to be replaced.

Keeping records of the working conditions and how well the bit works is useful for planning future drilling activities. Keeping track of the types of formations, drilling parameters, and video that is obtained helps improve the bit choice and operation methods for similar tasks.

Common Issues and Solutions

The most common way for PDC bits to fail is through cutter damage. Impact damage from hard stringers or wrong drilling settings can chip or crack individual cutters, making the bit less useful as a whole. Keeping the right amount of weight on the bit and controlling the rotating speed can help lower the impact pressure that causes cutters to break.

Bit balling happens when the shape cuts stick to the bit face. This makes cutting less effective and could lead to early wear. Changing the qualities of the drilling fluid or the rate of hydraulic flow can often fix balling problems without having to replace the bit.

Too much shaking can mean that the wrong bit was used or that the drilling settings were not set correctly. Five-blade PDC bits are less likely to vibrate than other designs because they are balanced. However, if they are not used correctly, they can still cause dangerous movements that hurt both the bit and the downhole tools.

Optimization Strategies

During the whole drilling operation, parameter tuning should be a continuous process. If the formation changes, the weight on the bit, the rotating speed, or the flow rate may need to be changed to keep the machine working at its best. 5 Blades PDC Oil Bits are very flexible, so they can have their parameters changed without affecting their performance too much.

Monitoring tools that work in real time give useful feedback for attempts to improve things. Modern drilling rigs with improved monitoring can give real-time information on how the bit is working, so changes can be made right away if conditions change.

Procurement Considerations for 5 Blades PDC Oil Bits

When the drilling business makes strategic buying choices, they have to weigh the short-term cost benefits against the long-term operational benefits. To choose the right PDC drilling technology, you have to look at several things that affect the overall cost of the job.

Supplier Evaluation Criteria

The quality of the manufacturing process is what makes 5 Blades PDC Oil Bits work reliably. Results are more likely to be consistent when you buy from suppliers who have a history of doing good work with diamond synthesis, precise cutter placement, and quality control. The manufacturer's image is often directly linked to how well and reliably the bit works in tough drilling conditions.

Superior sellers are different from commodity suppliers in that they can provide technical help. The buying relationship is greatly improved by having access to skilled application engineers who know the local geology and how to drill. These technical tools help you choose the best bits and set the right drilling settings for each job.

As drilling targets get tougher, the ability to customize becomes more and more important. In difficult drilling settings, suppliers who can change standard designs to fit specific formation features or operating needs give their companies a competitive edge.

Cost-Benefit Analysis Framework

When you look at the cost per foot, the initial buying price is only a small part of how much the bit costs altogether. Higher-quality bits usually explain their higher prices by giving you more footage and better entry rates. When comparing options, the study should look at things like how much time the rig saves, how often it needs to be moved, and how the wellbore quality improves.

When it comes to costs, bulk buying can save a lot of money for bigger digging projects. A lot of firms have tiered price systems that offer better technical support services and lower unit costs for bigger orders.

Why Choose HNS 5 Blades PDC Oil Bits?

HNS is the leader in PDC drilling technology because it combines cutting-edge design ideas with a track record of producing high-quality products. Our engineering team has come up with cutting-edge ways to deal with the problems that current drilling operations face.

In the crowded drilling market, these are the main things that make our goods stand out:

- New design for better cutting efficiency: our special blade shape optimization gets rid of as much rock as possible while using as little energy as possible. This lets you drill faster and protects your drilling equipment.

- Better resistance to wear for longer bit life: cutting-edge PDC technology mixed with precise production methods creates extreme durability, often far surpassing competing products by large amounts in similar tasks.

- Improved cuttings removal through optimized hydraulics: our junk slot design is based on computational fluid dynamics analysis, which makes sure that cleaning is as effective as possible across the full range of suggested working parameters.

- Faster drilling with a higher rate of penetration: the balanced five-blade design keeps the cutting action bold while giving it the steadiness it needs to improve the rate of penetration over time.

These technical advantages have direct effects on operational advantages that have an effect on the costs of the project. Our bits regularly show better performance ratings across a wide range of geological formations. This makes them the first choice for demanding drilling workers who need reliable results.

Because every drilling job is different, our modification services take that into account. HNS's experienced engineering team works closely with clients to create custom solutions that work best for their unique operational needs and formation features. This collaborative method makes sure that the whole drilling process is as efficient and cost-effective as possible.

Conclusion

Choosing the right drilling technology has a big effect on how well operations go in today's difficult drilling settings. Five-blade PDC oil bits are the best combination of cutting efficiency and operational stability. They work especially well in medium to hard formations that are popular in oil and gas production.

When buying, workers know the exact drilling conditions that make these tools work best, and they can make decisions that get the best return on investment. When you choose the right bits, set the right operating settings, and work with dependable suppliers, you can have good drilling operations that meet both technical and financial goals.

FAQ

Q1: What formations are best suited for 5 blades PDC oil bits?

Five-blade PDC bits perform optimally in medium-hardness formations with low to moderate compressive strength. Shale, limestone, sandstone, and gypsum formations typically respond well to this bit design. The balanced cutting action works particularly well in interbedded formations where varying rock properties require stable drilling performance.

Q2: How do operating parameters affect bit performance?

Proper parameter selection is crucial for maximizing bit life and penetration rates. Rotary speeds of 60-250 RPM, drilling pressures of 30-180 KN, and flow rates of 45-80 LPS provide optimal performance ranges. Exceeding these parameters can lead to premature cutter wear or bit failure, while insufficient parameters reduce drilling efficiency.

Q3: Can these bits handle directional drilling applications?

The balanced design of five-blade PDC bits makes them excellent choices for directional and horizontal drilling. The distributed cutting forces reduce bit walk tendency, improving directional control compared to more aggressive three-blade designs. This stability is particularly valuable in extended horizontal sections where maintaining wellbore geometry is critical.

Partner with HNS for Superior Drilling Performance

Transform your drilling operations with HNS advanced 5 Blades PDC Oil Bit technology designed for optimal performance in challenging formations. As a leading PDC drill bit manufacturer, we combine innovative engineering with proven reliability to deliver exceptional value for oil and gas drilling operations. Our experienced technical team provides customized solutions tailored to your specific geological conditions and operational requirements. Contact us today at hainaisen@hnsdrillbit.com or visit hnsdrillbit.com to discuss your drilling challenges and discover how our premium drilling solutions can enhance your operational efficiency.

References

1. Drilling Engineering Association, "PDC Bit Design Principles and Formation Applications," Journal of Petroleum Drilling Technology, 2023.

2. Smith, J.R., "Comparative Analysis of Multi-Blade PDC Bit Configurations in Sedimentary Formations," International Drilling Conference Proceedings, 2022.

3. Energy Technology Institute, "Optimization of Drilling Parameters for Enhanced PDC Bit Performance," Technical Publication Series, 2023.

4. Wilson, M.K., "Hydraulic Design Considerations in PDC Drill Bit Engineering," Society of Petroleum Engineers Technical Papers, 2022.

5. Advanced Drilling Technologies Research Group, "Formation-Specific Drilling Tool Selection Guidelines," Industry Technical Manual, 2023.

6. Thompson, R.L., "Economic Evaluation Methods for Drilling Tool Procurement," Petroleum Engineering Economics Quarterly, 2022.

VIEW MOREDiamond Coal Mine Picks

VIEW MOREDiamond Coal Mine Picks VIEW MOREHigh Performance 5 Cutter PDC Bit

VIEW MOREHigh Performance 5 Cutter PDC Bit VIEW MOREFour Blade PDC Drill Bit

VIEW MOREFour Blade PDC Drill Bit VIEW MORESteel Tooth Bit

VIEW MORESteel Tooth Bit VIEW MOREForging Deep Rock Well Drilling Bits PDC Mining Bit

VIEW MOREForging Deep Rock Well Drilling Bits PDC Mining Bit VIEW MOREHard Alloy Scraper Drill Bit

VIEW MOREHard Alloy Scraper Drill Bit VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit

VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit VIEW MOREDiamond Drill Bits For Oil Rigs

VIEW MOREDiamond Drill Bits For Oil Rigs