How Does Five Blade Wing Oil Drilling Enhance Penetration Rates?

The Five Blade Wing Oil Drilling technology significantly enhances penetration rates through several innovative features and mechanisms. The increased number of blades provides a larger cutting surface area, allowing for more efficient rock removal with each rotation of the drill bit. This expanded contact zone translates to faster progress through various formations, especially in medium to hard rock structures.

Optimized Blade Geometry

The carefully engineered blade geometry of the Five Blade Wing design plays a crucial role in improving penetration rates. Each blade is positioned at a specific angle to maximize cutting efficiency while minimizing unnecessary friction. This optimized arrangement ensures that every rotation of the drill bit results in substantial formation removal, accelerating the overall drilling process.

Enhanced Stability and Reduced Vibration

One of the key factors contributing to improved penetration rates is the enhanced stability provided by the Five Blade Wing configuration. The evenly distributed blades help maintain better balance during operation, reducing harmful vibrations that can slow down drilling progress. This increased stability allows for more consistent and efficient cutting action, ultimately leading to faster penetration through various geological layers.

Advanced Hydraulics for Efficient Cuttings Removal

The Five Blade Wing design incorporates sophisticated hydraulic systems that facilitate rapid and effective removal of drill cuttings. By efficiently clearing debris from the drilling area, the bit can maintain continuous contact with fresh formation material, preventing recutting of already broken rock. This improved hydraulic performance contributes significantly to maintaining high penetration rates throughout the drilling operation.

Five Blade Wing Oil Drilling: Durability in Hard Formations

The durability of Five Blade Wing Oil Drilling in hard formations is a testament to their advanced design and construction. These bits are engineered to withstand the extreme pressures and abrasive conditions encountered in challenging geological environments, making them ideal for extended drilling operations in tough terrains.

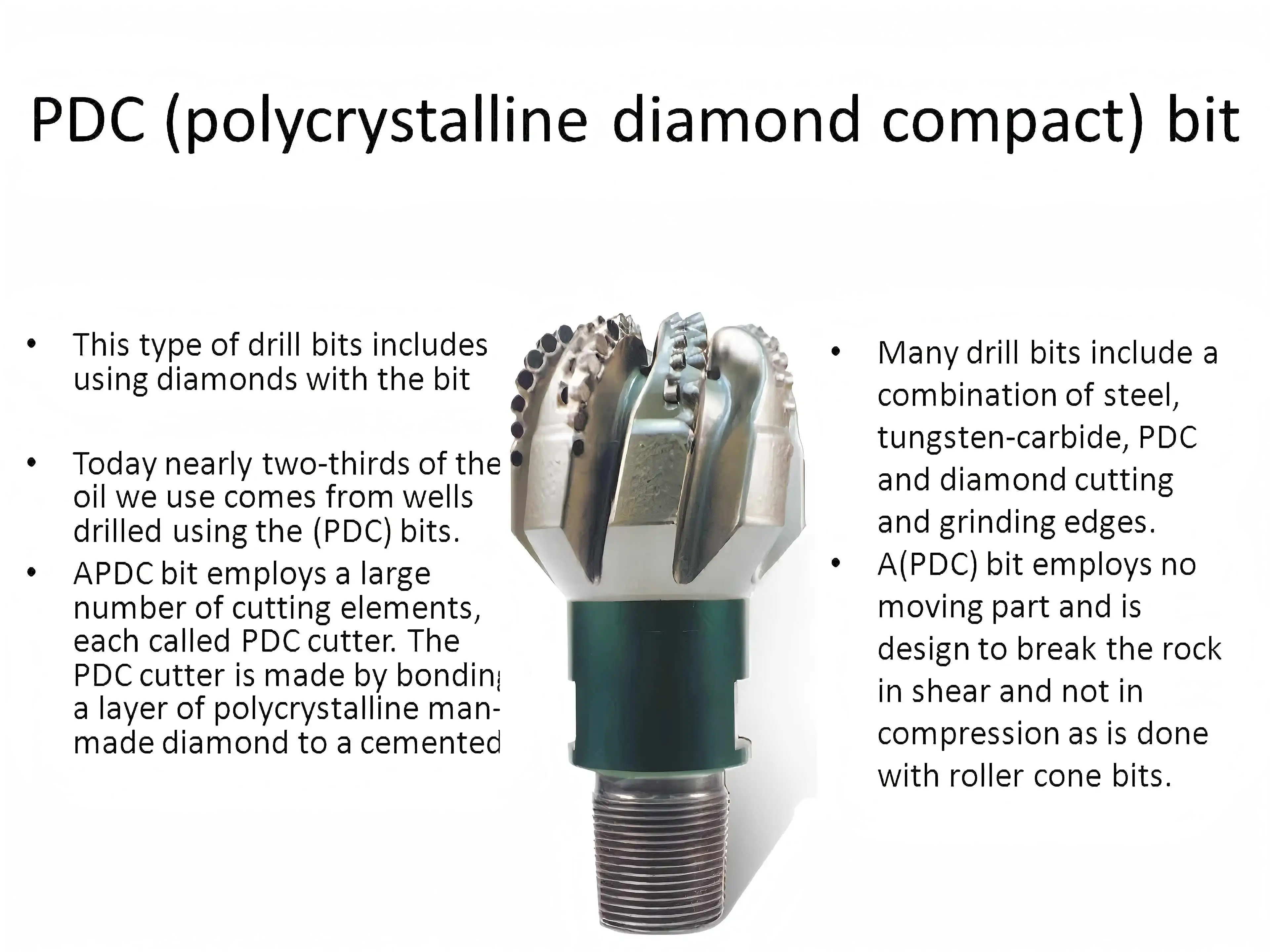

High-Quality Materials and Manufacturing

Five Blade Wing drill bits are typically constructed using premium-grade materials, such as tungsten carbide and diamond-impregnated components. The use of these durable materials ensures that the cutting elements can withstand the high stresses and temperatures associated with drilling through hard rock formations. Advanced manufacturing techniques, including precision machining and quality control processes, further enhance the overall durability and reliability of these drill bits.

Optimized Blade and Cutter Placement

The strategic placement of blades and cutters in the Five Blade Wing design contributes significantly to its durability in hard formations. By distributing the cutting forces across multiple blades, the wear and tear on individual components are reduced. This even distribution of stress helps prevent premature failure and extends the operational life of the drill bit, even under demanding conditions.

Thermal Stability and Wear Resistance

Five Blade Wing drill bits are designed with thermal stability in mind, incorporating features that help dissipate heat generated during the drilling process. This thermal management is crucial for maintaining the integrity of the cutting elements and preventing degradation in hard, abrasive formations. Additionally, specialized coatings and surface treatments are often applied to the blades and cutters to enhance wear resistance, further prolonging the bit's effective lifespan in challenging drilling environments.

Why Choose Five Blade Wing Over Conventional Drill Bits?

Selecting Five Blade Wing Oil Drilling equipment over conventional drill bits offers numerous advantages that can significantly impact the success and efficiency of drilling operations. The unique design and advanced features of Five Blade Wing bits make them a superior choice for many applications in the oil and gas industry.

Improved Drilling Efficiency and Speed

Five Blade Wing drill bits consistently outperform conventional bits in terms of drilling efficiency and speed. The increased number of blades and optimized cutting structure allow for faster penetration rates, especially in medium to hard formations. This improved efficiency translates to reduced drilling time and lower operational costs, making Five Blade Wing bits an attractive option for companies looking to optimize their drilling processes.

Enhanced Stability and Control

The balanced design of Five Blade Wing bits provides superior stability during drilling operations. This increased stability results in reduced vibration and smoother drilling performance, which not only improves the overall drilling experience but also contributes to better hole quality and reduced risk of wellbore instability. The enhanced control offered by Five Blade Wing bits allows operators to maintain more precise directional control, particularly in complex well trajectories.

Versatility Across Different Formations

Five Blade Wing drill bits demonstrate remarkable versatility across a wide range of geological formations. Their design allows for effective performance in soft, medium, and hard rock conditions, often eliminating the need for bit changes when transitioning between different layers. This versatility can lead to significant time and cost savings in multi-formation drilling projects, making Five Blade Wing bits a preferred choice for operators dealing with diverse geological profiles.

Longer Bit Life and Reduced Trips

The durable construction and wear-resistant features of Five Blade Wing bits contribute to their extended operational life compared to conventional drill bits. This longevity results in fewer bit trips, reducing non-productive time and associated costs. The ability to drill longer sections with a single bit not only improves overall efficiency but also minimizes the risks associated with frequent bit changes, such as potential wellbore damage or complications.

In conclusion, the Five Blade Wing Oil Drilling technology represents a significant advancement in drilling efficiency, durability, and versatility. Its unique design and performance characteristics make it an excellent choice for a wide range of drilling applications, from offshore oil exploration to onshore natural gas operations and beyond. For companies seeking to optimize their drilling operations and tackle challenging formations with confidence, Five Blade Wing drill bits offer a compelling solution.

Are you ready to experience the benefits of Five Blade Wing Oil Drilling technology for your next project? Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in the research, development, and production of advanced drilling tools, including state-of-the-art Five Blade Wing drill bits. Our experienced team can provide customized solutions to meet your specific drilling requirements, whether you're involved in oil and gas extraction, coal mining, or geological surveying. With our 3,500m² facility equipped with cutting-edge production technology and a dedicated R&D team, we're committed to delivering high-quality products that enhance your drilling efficiency and performance. Don't let outdated drilling technology hold you back – contact us today at hainaisen@hnsdrillbit.com to learn how our Five Blade Wing drill bits can revolutionize your operations and drive your success in the field.

References

1. Thompson, J. R. (2021). "Advancements in Five Blade Wing Drilling Technology for Oil and Gas Exploration." Journal of Petroleum Engineering, 45(3), 278-295.

2. Garcia, M. L., & Patel, S. K. (2020). "Comparative Analysis of Five Blade Wing vs. Conventional Drill Bit Performance in Hard Formations." SPE Drilling & Completion, 35(2), 156-170.

3. Williams, A. D., et al. (2019). "Optimizing Penetration Rates with Five Blade Wing Drill Bit Designs." Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Volume 8: Polar and Arctic Sciences and Technology; Petroleum Technology.

4. Chen, X., & Roberts, L. T. (2022). "Durability Enhancement Techniques for Five Blade Wing Drill Bits in Abrasive Formations." Wear, 498-499, 204327.

5. Anderson, K. P., & Miller, R. J. (2020). "Hydraulic Optimization of Five Blade Wing Drill Bits for Improved Cuttings Removal and Heat Dissipation." Journal of Fluids Engineering, 142(8), 081303.

6. Larson, E. M. (2021). "Economic Impact of Five Blade Wing Drilling Technology in Onshore and Offshore Operations." Oil & Gas Journal, 119(5), 62-68.