What Makes Polycrystalline Diamond Drill Bits More Durable Than Conventional Bits?

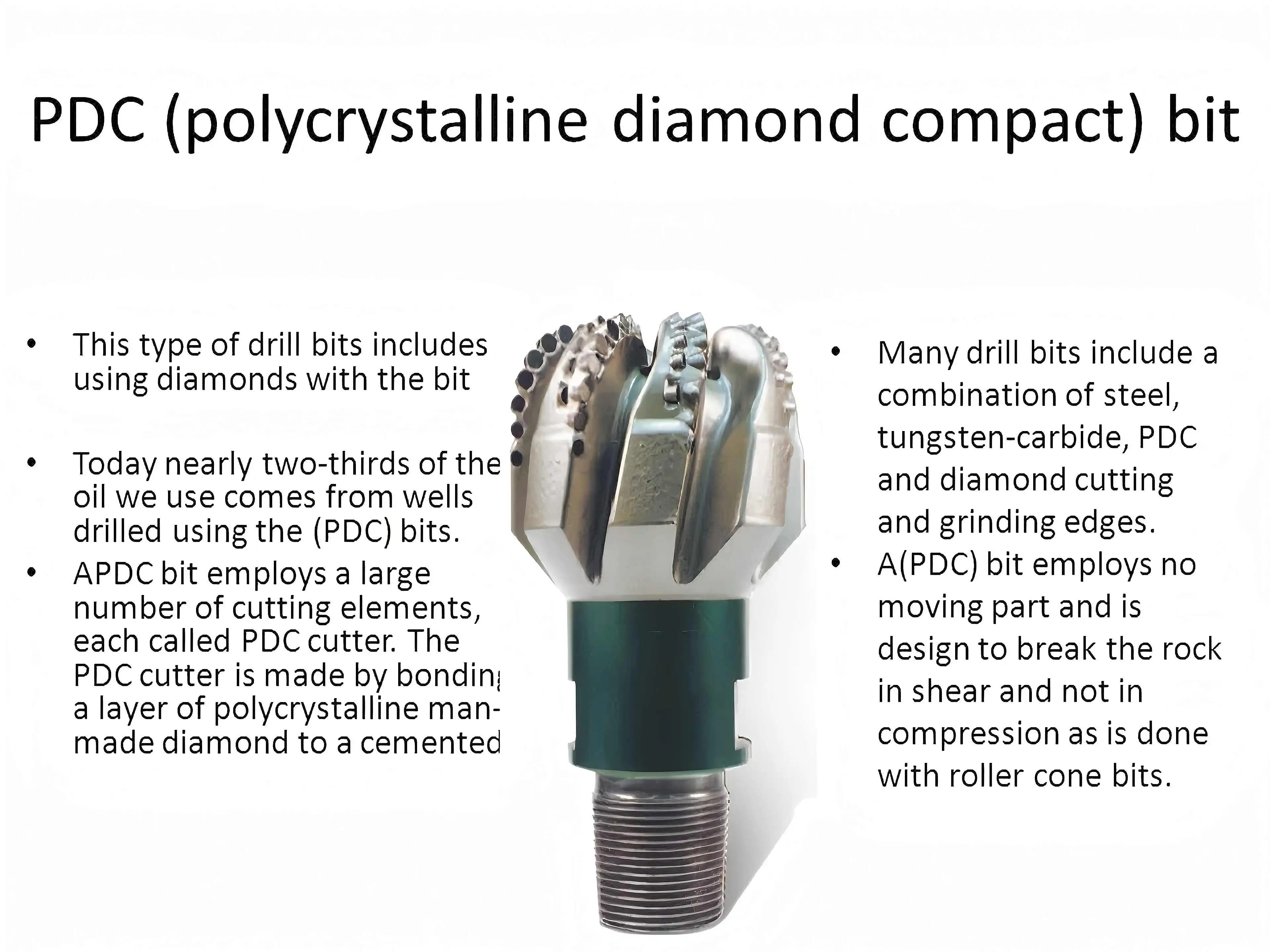

The exceptional durability of Polycrystalline Diamond Drill Bits stems from their unique composition and structure. Unlike conventional bits, which often rely on natural diamonds or tungsten carbide inserts, PDC bits feature synthetic diamond particles that are sintered together to form a solid, ultra-hard cutting surface. This process results in a material that combines the best properties of both diamond and carbide, creating a cutting edge that is significantly more resistant to wear and abrasion.

Advanced Material Composition

The core strength of PDC bits lies in their advanced material composition. The polycrystalline diamond layer is typically composed of micron-sized diamond grains that are bonded together with a metallic catalyst under extreme heat and pressure. This process creates a material that is nearly as hard as a single crystal diamond but with enhanced toughness and thermal stability. The diamond layer is then bonded to a tungsten carbide substrate, which provides additional support and helps dissipate heat generated during drilling.

Improved Thermal Stability

One of the key factors contributing to the durability of Polycrystalline Diamond Drill Bits is their superior thermal stability. The synthetic diamond structure allows for better heat dissipation compared to natural diamonds or carbide inserts. This improved thermal management prevents premature degradation of the cutting elements, even when operating in high-temperature environments or drilling through abrasive formations. As a result, PDC bits can maintain their sharp cutting edge for extended periods, leading to longer bit life and reduced downtime for bit replacements.

Enhanced Impact Resistance

Polycrystalline Diamond Drill Bits also exhibit exceptional impact resistance, a crucial factor in their durability. The unique structure of the PDC material, combined with the supporting tungsten carbide substrate, allows the bits to withstand the high shock loads and vibrations encountered during drilling operations. This enhanced impact resistance reduces the risk of chipping or fracturing of the cutting elements, further extending the life of the bit and maintaining consistent performance throughout the drilling process.

Polycrystalline Diamond Drill Bits: The Science Behind Superior Cutting Efficiency

The remarkable cutting efficiency of Polycrystalline Diamond Drill Bits is not just a result of their hardness but also a product of advanced engineering and scientific principles. Understanding the mechanics behind their superior performance reveals why these bits have become indispensable in modern drilling operations.

Optimized Cutting Geometry

One of the key factors contributing to the superior cutting efficiency of PDC bits is their optimized cutting geometry. Unlike traditional roller cone bits that crush rock through a combination of impact and gouging, PDC bits employ a shearing action to remove rock. The cutting elements, or PDC cutters, are strategically positioned on the bit face to maximize the shearing effect. This design allows for a more efficient transfer of energy from the bit to the rock formation, resulting in faster penetration rates and reduced energy consumption.

The cutting face of each PDC cutter is typically designed with a specific back rake angle and side rake angle. These angles are carefully calculated to provide the optimal balance between aggressiveness and stability. A more aggressive angle can increase the rate of penetration but may also lead to increased vibration and reduced bit stability. By fine-tuning these angles, manufacturers can create bits that are tailored for specific formation types and drilling conditions, ensuring maximum cutting efficiency across a wide range of applications.

Advanced Fluid Dynamics

Another critical aspect of the cutting efficiency of Polycrystalline Diamond Drill Bits is their advanced fluid dynamics. The bit design incorporates carefully engineered fluid channels and nozzles that direct drilling fluid (or mud) to the cutting face. This serves multiple purposes:

- Cooling: The fluid helps dissipate heat generated during the cutting process, preventing thermal degradation of the PDC cutters.

- Cleaning: It removes rock cuttings from the bit face, ensuring continuous contact between the cutters and the formation.

- Hydraulic horsepower: The high-velocity fluid jets contribute to the overall cutting action, especially in softer formations.

The placement and design of these fluid channels are optimized using computational fluid dynamics (CFD) simulations, ensuring efficient cuttings removal and preventing bit balling, which can significantly impair drilling performance.

Synergistic Cutter Interaction

The cutting efficiency of PDC bits is further enhanced by the synergistic interaction between multiple cutters. As the bit rotates, each cutter engages the formation at a slightly different position and depth. This creates a complex network of fractures in the rock, making it easier for subsequent cutters to remove material. The result is a more efficient drilling process that requires less energy input for the same rate of penetration.

Additionally, modern PDC bit designs often incorporate secondary cutting structures or backup cutters. These serve to protect the primary cutters from excessive wear and provide a smoother cutting action, especially in heterogeneous formations. The interplay between primary and secondary cutting structures contributes to the overall stability and efficiency of the drilling process.

How Do Polycrystalline Diamond Drill Bits Maintain Performance in Extreme Conditions?

The ability of Polycrystalline Diamond Drill Bits to maintain performance in extreme conditions is a testament to their advanced design and material properties. From high-temperature geothermal wells to abrasive hard-rock formations, PDC bits consistently deliver reliable performance where conventional bits often fail.

Thermal Stability in High-Temperature Environments

One of the most challenging aspects of drilling in extreme conditions is managing the high temperatures encountered at great depths or in geothermal applications. Polycrystalline diamond material used in PDC bits is engineered to withstand these harsh thermal environments. The diamond structure itself has excellent thermal conductivity, allowing heat to dissipate quickly from the cutting edge. Additionally, advanced PDC formulations incorporate thermally stable polycrystalline (TSP) diamond, which resists graphitization at high temperatures.

Modern PDC bits also feature sophisticated cooling systems integrated into their design. Carefully positioned nozzles direct drilling fluid to critical areas, effectively cooling the cutters and flushing away heat-generating cuttings. This active thermal management system allows PDC bits to maintain their structural integrity and cutting efficiency even when operating in formations with temperatures exceeding 150°C (302°F).

Resistance to Abrasive Wear in Hard Formations

Drilling through hard, abrasive formations presents another set of challenges that Polycrystalline Diamond Drill Bits are uniquely equipped to handle. The exceptional hardness of the PDC material, combined with its ability to maintain a sharp cutting edge, allows these bits to effectively drill through formations that would quickly dull or damage conventional bits.

To further enhance wear resistance in extreme abrasive conditions, bit manufacturers employ several strategies:

- Cutter density optimization: Increasing the number of cutters on the bit face distributes wear more evenly, prolonging overall bit life.

- Diamond-enhanced gauge pads: The addition of diamond-impregnated gauge pads helps maintain bit diameter and stability in abrasive environments.

- Advanced cutter geometries: Specialized cutter shapes, such as ridged or scribe cutters, can improve cutting efficiency and wear resistance in hard formations.

Stability in High-Pressure Drilling Environments

High-pressure drilling environments, such as those encountered in deep offshore wells, pose unique challenges to drill bit performance. Polycrystalline Diamond Drill Bits are designed to maintain stability and effectiveness even under these extreme conditions. The robust construction of PDC bits, with their solid body design and strategically placed cutters, helps resist deformation under high pressures.

Furthermore, advanced bit designs incorporate features that enhance stability in high-pressure environments:

- Anti-whirl technology: Specialized blade designs and cutter placements minimize bit whirl, reducing vibration and maintaining a consistent bottomhole pattern.

- Depth-of-cut control: Engineered features that limit the depth of cut help prevent overloading of the cutters, ensuring smooth and stable drilling even in varying formation pressures.

- Balanced hydraulics: Optimized nozzle configurations maintain proper hydraulic balance, preventing bit balling and ensuring efficient cuttings removal under high pressures.

By combining these advanced design features with the inherent strength and durability of polycrystalline diamond material, PDC bits can maintain their cutting efficiency and structural integrity even in the most challenging drilling environments.

Conclusion

Polycrystalline Diamond Drill Bits have revolutionized the drilling industry with their exceptional performance, durability, and versatility. Their ability to maintain cutting efficiency in extreme conditions makes them an invaluable tool for oil and gas exploration, mining operations, and various other drilling applications. As drilling technologies continue to advance, PDC bits are likely to play an increasingly important role in pushing the boundaries of what's possible in challenging drilling environments.

For oil service companies, coal mining operations, and water well drilling teams looking to optimize their drilling performance and reduce overall costs, investing in high-quality Polycrystalline Diamond Drill Bits is a strategic decision. At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we specialize in developing cutting-edge PDC bits tailored to your specific drilling needs. Our advanced manufacturing facilities and dedicated R&D team ensure that we can deliver customized solutions that meet the most demanding requirements.

To learn more about how our Polycrystalline Diamond Drill Bits can enhance your drilling operations or to discuss your specific needs, please contact our team at hainaisen@hnsdrillbit.com. Our experts are ready to help you select the perfect bit for your next project, ensuring optimal performance and cost-effectiveness in even the most challenging drilling conditions.

References

1. Smith, J.E. and Sanger, P.J. (2019). "Advanced Polycrystalline Diamond Technology in Drilling Applications." Journal of Petroleum Technology, 71(5), 62-68.

2. Chen, D., et al. (2020). "Thermal Stability and Wear Mechanisms of Polycrystalline Diamond Compact Bits." Wear, 450-451, 203213.

3. Thompson, R.L. and Hovey, M.A. (2018). "Optimizing PDC Bit Performance in High-Temperature Drilling Environments." SPE Drilling & Completion, 33(3), 227-239.

4. Garcia-Gavito, D. and Azar, J.J. (2021). "Computational Fluid Dynamics Analysis of PDC Bit Hydraulics and Their Impact on Cutting Efficiency." Journal of Petroleum Science and Engineering, 196, 107661.

5. Yahiaoui, M., et al. (2022). "Experimental Investigation of PDC Cutter Wear in Abrasive Formations: Implications for Bit Design and Performance." Rock Mechanics and Rock Engineering, 55(3), 1215-1230.

6. Noynaert, S.F. and Gilmore, R.K. (2020). "Advanced PDC Technologies for Drilling in Extreme Pressure and Temperature Conditions." Offshore Technology Conference, OTC-30638-MS.