China's 4 Wings Blades PDC Bit manufacturing sector continues to evolve rapidly, positioning itself as a global leader in drilling technology solutions. These specialized equipment have changed the way drilling is done in the oil and gas exploration, coal mining, and water well construction industries. The four-wing design makes cutting more efficient, makes the tool last longer, and makes it more stable during drilling. Chinese companies have spent a lot of money on research and development to make new polycrystalline diamond compact technologies that meet international quality standards. Choosing the correct manufacturer is very important for the success of a project because oil service firms and mining operations throughout the world are asking for more and more. This in-depth study looks at the ten best OEM/ODM firms in 2025, based on their technological quality, manufacturing capacity, and customer satisfaction.

Leading Chinese Manufacturers of 4 Wings Blades PDC Bits

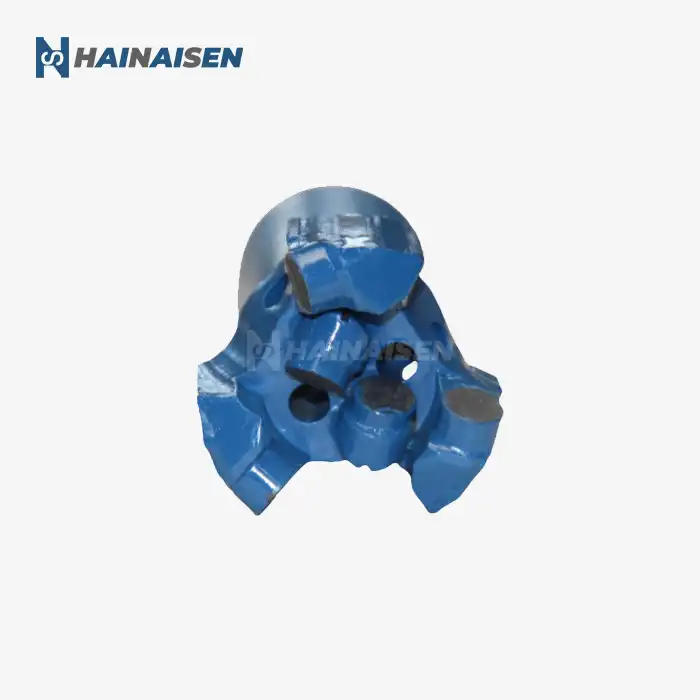

1. Shaanxi Hainaisen Petroleum Technology Co., Ltd.

Shaanxi Hainaisen Petroleum Technology Co., Ltd. was founded in 2013 and is situated in Xi'an. It is now one of the best companies in the world at making diamond drill bits and PDC drilling equipment. The company has a state-of-the-art 3,500m² facility with powerful 5-axis machining centers, CNC machine tools, and automated welding lines. This makes sure that high-performance drilling tools are made with accuracy and speed. Hainaisen specializes in 4 Wings Blades PDC Bit technology. They use high-quality steel bodies and modern polycrystalline diamond compact (PDC) cutters to make bits that last longer and resist wear even in tough drilling situations.

Hainaisen's team of skilled engineers and researchers is dedicated to designing unique bits that can fulfill the needs of a wide range of sectors, including oil and gas extraction, coal mining, and geological surveys. Their 4 Wings Blades PDC Bit is designed to cut very well and last a long time, making it perfect for a wide range of geological formations, such as shale, limestone, and sandstone. The company's strict quality control procedures include thorough testing techniques that go above and beyond what is required in the industry. This guarantees that each product will work and be reliable. Hainaisen is a reliable provider to both medium and large oil service organizations. They can make more than 10,000 units a year and offer affordable prices and high-quality solutions for drilling operations of all kinds. Because they are dedicated to coming up with new ideas and making customers happy, they are one of the best 4 Wings Blades PDC Bit manufacturers in China.

2. Kingdream Public Ltd.

Kingdream is now one of the top companies in China that makes PDC drill bits. The company is based in Beijing and has a lot of research and manufacturing facilities that help it serve both domestic and international markets. Their four-wing PDC bits have new cutting features that make them better at drilling in different types of rocks. The company's technical advantages include its own matrix materials that are very stable at high temperatures and resistant to impact. Kingdream uses ISO 9001 quality management systems in its manufacturing processes to make sure that its products are always reliable. They can export more than 15,000 units a year, and they work with big oil service firms in North America, the Middle East, and Southeast Asia. The company spends about 8% of its yearly revenue on research and development, with an emphasis on next-generation cutting technologies and algorithms for optimizing bits.

3. Jilin Geological Drilling Bit Manufacturing Co.

Located in northeastern China, Jilin Geological Drilling Bit Manufacturing Co. specializes in producing highly durable drill bits for geological exploration and mining applications. The company’s deep expertise in metallurgy and diamond technology allows them to produce robust drilling tools designed for challenging geological formations. Their 4 Wings Blades PDC Bit incorporates specialized matrix compositions that enhance thermal resistance and cutting efficiency, making it ideal for tough drilling environments.

Jilin Geological Drilling's focus on advanced materials and cutting-edge production techniques ensures that their 4 Wings Blades PDC Bit provides exceptional performance in a range of applications, from oil and gas extraction to mineral exploration. Their rigorous quality management system includes comprehensive material testing and performance validation procedures to guarantee the reliability and longevity of their products.

With over two decades of manufacturing experience, they serve numerous geological surveying organizations and mineral exploration companies. Their competitive pricing strategy makes them particularly attractive to water well drilling teams and smaller mining operations.4. Beijing Jingang Diamond Tools Co.

This Beijing-based manufacturer focuses on advanced diamond tool technologies, including sophisticated PDC bit designs for various drilling applications. Their technical capabilities encompass both synthetic diamond production and precision bit assembly. The company's four-wing configurations feature optimized cutter placement patterns that maximize penetration rates while maintaining bit stability. Their manufacturing facility includes specialized brazing equipment and quality testing laboratories that ensure consistent product performance. Annual production exceeds 8,000 units, with significant export volumes to international markets. Their R&D initiatives concentrate on developing next-generation cutting technologies and improving bit wear resistance.5. Chongqing Geological Drilling Equipment Co.

This Chongqing-based company makes specialized PDC bits for geological sampling and exploration. They focus on core drilling bit technology. They are experts in advanced bit design software and precision production. The company makes a wide range of products, including unique four-wing configurations for certain types of formations and drilling circumstances. They use advanced measurement equipment and performance testing techniques as part of their quality control operations. They have significant ties to the geological exploration business, which keeps demand stable from customers in the US and around the world. Their ecologically friendly manufacturing procedures and efforts to cut down on waste are part of their commitment to sustainable development.

6. Urumqi Diamond Drilling Tools Ltd.

Located in western China's resource-rich region, Urumqi Diamond Drilling Tools Ltd. specializes in producing robust drilling tools designed for challenging geological conditions. Their strategic proximity to major mining operations provides them with valuable insights into real-world drilling requirements, enabling them to create highly effective solutions. Their 4 Wings Blades PDC Bit designs prioritize durability and consistent performance, especially in abrasive formations, making them an ideal choice for tough drilling environments. Urumqi Diamond Drilling's manufacturing capabilities include advanced heat treatment processes and precision machining systems, ensuring the highest quality and reliability of their products. The 4 Wings Blades PDC Bit is specifically engineered to withstand the harsh demands of mining and geological exploration, offering superior wear resistance and extended operational life.

The company serves a diverse customer base, including major mining equipment suppliers and regional drilling contractors. With an annual production capacity approaching 6,000 units, Urumqi Diamond Drilling Tools Ltd. maintains competitive positioning in the market through efficient production processes and responsive customer service. Their 4 Wings Blades PDC Bit remains a trusted solution for customers seeking high-performance, cost-effective drilling tools for demanding applications.

7. Dalian Drilling Technology Co.

This coastal company makes specialized PDC bits for use on land and at sea by combining marine engineering know-how with new drilling technology. Their technical staff is made up of engineers with knowledge in petroleum technology. The four-wing designs of the company use materials that don't rust and better sealing systems that work well in tough conditions. Their quality management strategy includes a lot of field testing and feedback from customers. They keep increasing their production capacity to fulfill the growing demand from oil service firms, thanks to their good financial performance and increased market share.8. Lanzhou Drilling Equipment Manufacturing

Based in northwestern China, this manufacturer focuses on producing cost-effective drilling solutions for regional and international markets. Their manufacturing processes emphasize efficiency and quality consistency. Their PDC bit portfolio includes standard and custom four-wing configurations designed for medium-hardness formations. The company's competitive advantages include streamlined production processes and responsive customer support. Their annual output serves numerous drilling contractors and equipment suppliers across Asia and the Middle East. With ongoing investments in manufacturing technology, they continue improving product quality and expanding market presence.