To choose the best 5 Blade Steel Body PDC Bit, you need to carefully think about your drilling parameters, the geology of the area, and your goals for the operation. This complete guide covers important topics like cutting structure design, the quality of the steel body construction, and the specifications for polycrystalline diamond compacts. It helps drilling professionals make smart buying choices that increase drilling efficiency while lowering operational costs.

Understanding 5 Blade Steel Body PDC Bit Technology

The development of PDC drill bit technology has changed the way drilling is done in several sectors today. Steel body structure makes these instruments far more durable than matrix competitors, which makes them especially useful in tough downhole situations. The five-blade design strikes the best mix between cutting speed and mechanical stability.

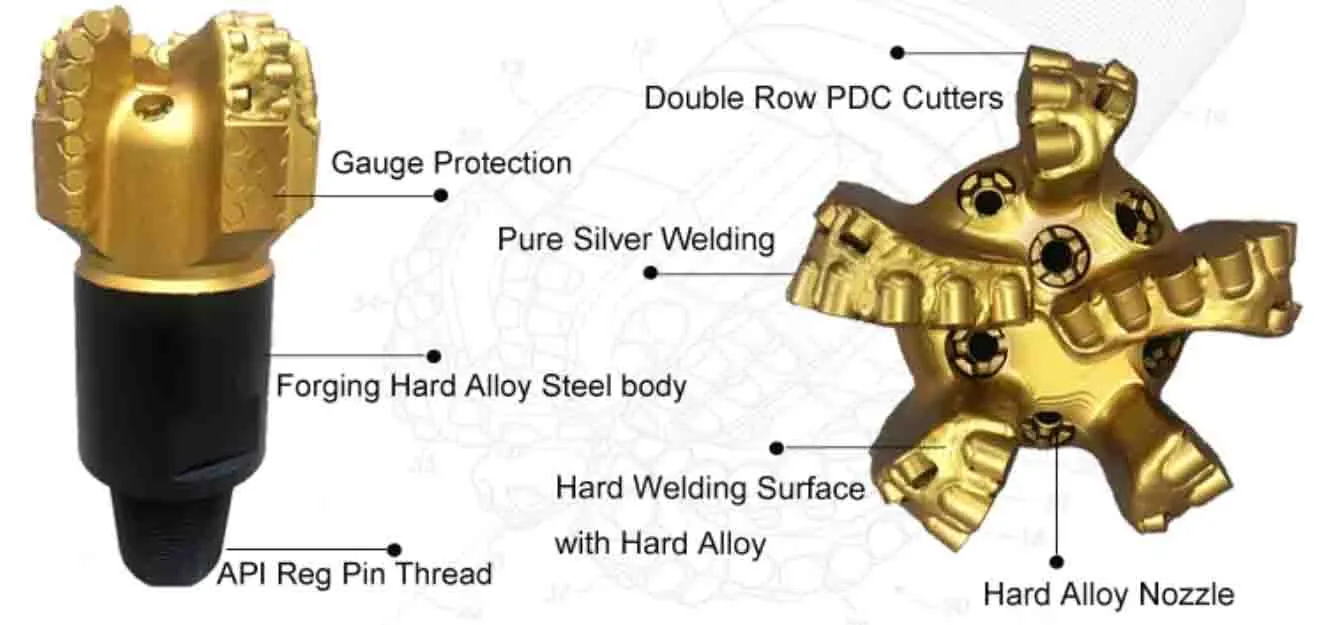

Polycrystalline diamond compact technique makes synthetic diamond particles stick together under very high pressure and temperature, which makes them far more resistant to wear and tear. This cutting structure keeps its sharpness during long drilling operations, which leads to steady penetration rates. Steel body bits can handle more drilling torque and are great at getting rid of heat.

The blade geometry of the 5 Blade Steel Body PDC Bit plays a critical role in its performance. Manufacturers design these cutting profiles to optimize rock drilling efficiency for specific geological formations. Additionally, proper bit hydraulics ensure effective cuttings removal while simultaneously cooling the cutting structure, prolonging the life of the bit and enhancing overall performance during operation.

Critical Factors for Different Industry Applications

Oil and gas drilling operations demand exceptional reliability and consistent performance. Large service companies typically require extensive testing protocols and quality certifications before approving new suppliers. These organizations prioritize bit longevity and wellbore stability over initial procurement costs.

Coal mining applications present unique challenges requiring specialized cutting structures. Mining drill bits must handle abrasive conditions while maintaining cost-effectiveness. The drilling optimization process focuses on maximizing footage per bit while controlling operational expenses.

Water well drilling teams often operate with tighter budget constraints. These smaller organizations emphasize price competitiveness while maintaining adequate drilling speed. Bit durability becomes crucial for maintaining profitability across multiple projects.

Geological exploration requires precise drilling capabilities for core sampling operations. Scientific drilling applications demand consistent bit performance to preserve sample integrity throughout the drilling process.

Technical Specifications and Operating Parameters

Optimal operating parameters are critical for ensuring the performance and longevity of a drill bit. For the 5 Blade Steel Body PDC Bit, recommended rotational speeds range from 60 to 250 RPM, depending on the formation characteristics and bit design specifications. Excessive speeds can lead to premature wear or thermal damage to the cutting elements, affecting the overall efficiency of the bit.

Drilling pressure application requires careful calibration between 20 to 110 KN. Insufficient weight on bit reduces penetration rates, while excessive pressure can cause cutting structure damage or bit steering issues. Flow rates between 30-40 LPS ensure adequate hydraulic cleaning and cooling.

Formation compatibility plays a vital role in bit selection. Medium hardness formations including shale, limestone, sandstone, and gypsum respond well to five-blade configurations. These geological conditions allow optimal cutting action while preventing excessive bit wear.

Downhole drilling conditions including temperature, pressure, and fluid chemistry influence material selection and design specifications. Harsh environments require enhanced metallurgy and specialized protective coatings.

Quality Assessment and Supplier Evaluation

The quality of the manufacturing has a direct effect on drilling performance and safety. Advanced production facilities that use CNC machining and precise welding make sure that product standards are always the same. Quality control systems must check the correctness of the placement of the cutting elements and the metallurgy of the steel body.

In addition to making things, suppliers can also offer technical assistance and customizing services. Experienced manufacturers give advice based on the conditions of the drill and the goals of the operation. Custom bit design services help with drilling needs or geological problems that are different from the norm.

Testing protocols validate bit performance under controlled conditions before field deployment. Comprehensive testing includes cutting structure durability, hydraulic flow characteristics, and mechanical stress resistance. Documentation provides performance baselines for field comparison.

Certification standards guarantee compliance with industry safety and performance requirements. International quality benchmarks help guide global procurement decisions, ensuring that the 5 Blade Steel Body PDC Bit meets the expectations of customers worldwide.

Cost-Benefit Analysis and ROI Considerations

Total cost of ownership encompasses initial procurement price plus operational expenses throughout bit life. Premium bits with superior wear resistance often provide better economic value despite higher upfront costs. Calculating cost per foot drilled reveals true economic performance.

Drilling efficiency improvements reduce rig time and operational expenses. Faster penetration rates and extended bit life directly impact project economics. Reduced trip frequency minimizes non-productive time and associated costs.

Maintenance requirements and replacement scheduling affect operational planning. Predictable bit performance enables better resource allocation and project scheduling. Consistent drilling speed maintains project timeline integrity.

Risk mitigation through reliable bit performance prevents costly drilling problems including stuck pipe, wellbore instability, or equipment damage. Insurance against operational failures justifies premium bit investments for critical applications.

Conclusion

Selecting the optimal 5 Blade Steel Body PDC Bit requires balancing performance requirements with operational constraints. Technical specifications, supplier capabilities, and total cost considerations all influence procurement decisions. Quality manufacturing, proven field performance, and comprehensive technical support ensure successful drilling operations across diverse applications. HNS combines advanced technology with industry expertise to deliver reliable drilling solutions that meet evolving market demands.

Why HNS 5 Blade Steel Body PDC Bits Deliver Superior Performance

Shaanxi Hainaisen Petroleum Technology stands as a trusted 5 Blade Steel Body PDC Bit manufacturer with over a decade of engineering excellence. Our Xi'an facility combines advanced manufacturing capabilities with dedicated research and development teams to deliver cutting-edge drilling solutions.

Our enhanced cutting efficiency stems from optimized blade geometry developed through extensive field testing. The cutting structure design maximizes penetration rates while maintaining mechanical stability across diverse geological conditions. Superior wear resistance extends operational life, reducing replacement frequency and associated costs.

Manufacturing precision using 5-axis machining centers ensures consistent product quality and performance reliability. Our welding production lines create durable steel body construction capable of withstanding extreme downhole conditions. Quality assurance protocols verify every bit meets stringent performance standards.

Technical support services include application-specific recommendations and custom design capabilities. Our engineering team collaborates with customers to optimize drilling performance for unique operational challenges. Whether you need standard configurations or specialized solutions, HNS delivers reliable drilling tools backed by comprehensive support.

Ready to enhance your drilling operations with proven PDC technology? Contact our technical specialists to discuss your specific requirements and discover how our innovative solutions can improve your drilling efficiency. Reach out to us today at hainaisen@hnsdrillbit.com for detailed product information and competitive pricing.

References

1. American Petroleum Institute. "Specification for PDC Drill Bits." API Specification 7-1, 2019.

2. Society of Petroleum Engineers. "Advanced Drilling Bit Technology and Performance Optimization." SPE Drilling Engineering Journal, 2020.

3. International Association of Drilling Contractors. "Best Practices for PDC Bit Selection and Application." IADC Technical Manual, 2021.

4. Journal of Petroleum Science and Engineering. "Steel Body vs Matrix Body PDC Bits: Comparative Performance Analysis." Volume 195, 2020.

5. Mining Engineering Magazine. "PDC Bit Technology Advances in Coal and Mineral Drilling Applications." SME Publications, 2019.

6. World Oil Magazine. "Five-Blade PDC Bit Design Optimization for Enhanced Drilling Performance." Hart Energy Publishing, 2021.