Thermal Stability of Cutters in a 6 Wings PDC Drill Bit

It is very important for drilling processes to be thermally stable, especially when using high-tech drilling tools like the 6 Wings PDC Drill Bit. Extreme temperatures that happen during drilling operations can damage polycrystalline diamond compact cutters, but this important feature decides how well they keep their structure and cutting performance. Compared to standard designs, the six-wing configuration better distributes heat, making it easier to control the temperature across the whole cutting area. For procurement workers and technical experts who want to get the best drilling results with the least amount of costs and downtime, understanding thermal stability is important.

Understanding the Thermal Stability of Cutters in 6 Wings PDC Drill Bits

When it comes to PDC cutters, thermal stability basically means that they can handle big changes in temperature without losing their structural integrity or cutting ability. During digging, friction between the cutter and the rock forms can cause temperatures to rise quickly, possibly to levels that would damage normal cutting materials.

Critical Temperature Thresholds for PDC Performance

Within certain temperature ranges, PDC cuts work best, and under normal circumstances, they can stay stable up to 750°C (1382°F). Beyond this point, heat degradation starts to affect the structure of the polycrystalline diamond, which makes it less effective at cutting and causes it to wear out faster. The 6 Wings PDC Drill Bit shape helps spread heat loads more evenly across the bit face, which stops areas from getting too hot, which could hurt the performance of a single cutter.

Heat Generation Mechanisms in Drilling Operations

During drilling, heat is generated by a number of things, such as mechanical friction, compression forces, and chemical reactions between drilling fluids and rock formations. The new six-wing shape solves these problems by making the best use of cutter placement and angle configurations. This lowers frictional heating while keeping the cutting action strong. This way of designing reduces the number of places where heat stress builds up, which is a problem with most other drill bit designs.

Material Composition Impact on Thermal Resilience

Modern PDC cuts use advanced polycrystalline diamond alloys that have special bonding agents and crystal structures that make them more stable at high temperatures. These materials are very good at resisting thermal shock and keep their sharp edges even when exposed to high temperatures for a long time. The tungsten carbide base helps move heat away from the cutting edge more efficiently by making it more thermally conductive.

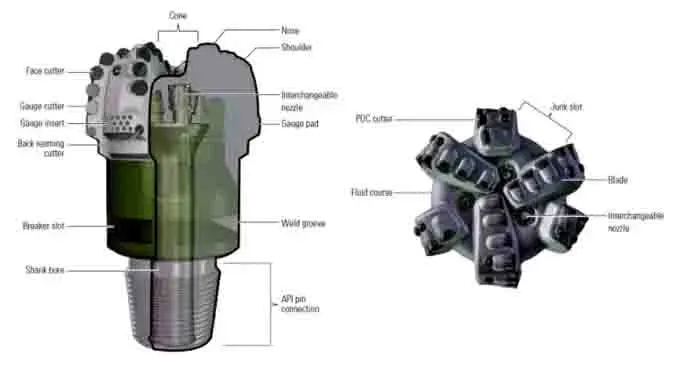

Design Features of 6 Wings PDC Drill Bits that Enhance Cutter Thermal Stability

The 6 Wings PDC Drill Bit shape is a big step forward in drill bit design. It has many structural and practical benefits that directly lead to better thermal stability. This design theory deals with thermal management by using strategic engineering methods that make the best use of heat distribution and reduce the buildup of thermal stress.

Strategic Cutter Placement and Angle Optimization

The six-wing design lets you place the cutter more strategically across the bit face, making the best cutting angles that keep the strong cutting action while lowering frictional heating. The placement of the cutters on each wing was carefully thought out to make sure that cutting forces are spread out evenly and that heat hotspots don't form that could damage the cutters. This balanced method makes sure that all cutting areas have the same temperature.

The six-wing design's advanced cutter angle configurations effectively slice rocks instead of breaking them, which produces a lot less heat during the cutting process. The optimized geometry lowers the area where cutters touch rock forms at any given time. This lets the rock cool naturally between cutting processes and stops heat from building up over time.

Enhanced Heat Dissipation Through Improved Hydraulics

The 6 Wings PDC Drill Bit design makes better pathways for fluid flow that improve the efficiency of cooling during drilling operations. These improved hydraulic paths make sure that there is enough drilling fluid moving around each cutter. This keeps the temperature at the right level by continuously cooling the cutters and clearing away waste. The design encourages flow patterns that are rough, which move heat away from cutting areas as quickly as possible.

A more efficient hydraulic system also helps remove cuts more effectively, keeping rock chips from building up and causing more friction and heat. The six-wing design's smart placement of fluid courses makes sure that cooling fluid gets to all the important parts of the bit face. This keeps the bit's temperature under control throughout the drilling process.

Advanced Material Integration and Bonding Technologies

Modern 6 Wings PDC Drill Bits are made with cutting-edge polycrystalline diamond alloys that are very stable at high temperatures. In these high-tech materials, there are new gluing technologies that keep the structure strong even at very high temperatures. This makes cutters last a lot longer and be more reliable.

Adding tungsten carbide matrices to the bit body improves its thermal conductivity. This makes it easier for heat to escape from critical cutting areas by building efficient heat dissipation paths. This mix of materials makes sure that the bit's thermal loads are spread out evenly rather than being focused at specific cutting spots.

Common Thermal Challenges in 6 Wings PDC Drill Bits and How to Overcome Them

Even though they have advanced design features, 6 Wings PDC Drill Bits can have problems with heat that affect their performance and how well they work. Understanding these problems and using the right ways to deal with them will ensure that drilling goes smoothly and equipment lasts longer.

Thermal Cracking and Cutter Degradation Issues

When fast temperature changes are too great for the material's thermal shock resistance, thermal breaking usually happens. This is one of the biggest problems with PDC cutters. This can show up as tiny cracks on the surface that get bigger over time as the temperature changes, finally breaking the cutting.

To avoid thermal cracking, you need to pay close attention to the drilling factors, especially the weight on the bit and the rotating speed settings. By staying within the suggested ranges for parameters (60–250 RPM and 20–110 KN drilling pressure), you can keep temperatures within acceptable limits and get the best entry rates and drilling efficiency.

Heat Buildup Prevention Through Operational Optimization

Keeping heat from building up requires adjusting a lot of different operating factors at the same time. These include the flow rates of drilling fluid, the patterns of circulation, and the drilling parameters. Keeping the flow rates between 30 and 40 LPS makes sure that there is enough cooling and hydraulic power to get rid of the cuttings effectively.

By keeping an eye on the drilling factors on a regular basis, workers can spot signs of thermal stress before they damage the equipment. Using automated parameter control systems can help keep the right temperature levels during drilling operations. This lowers the risk of heat breakdowns and increases the life of the equipment.

Proactive Maintenance Strategies for Thermal Management

Creating thorough maintenance plans that include thermal management can help keep expensive equipment from breaking down and keep operations running smoothly. When you check your cutter regularly, you should look for early signs of heat damage, such as darkening, micro-cracks, or wear patterns that don't make sense.

By using thermal tracking technologies in predictive maintenance methods, operators can find possible thermal problems before they affect the performance of the drilling. This proactive method lets people step in at the right time to stop major fails and keep drilling running at its best until the project is finished.

Comparative Performance: Thermal Stability of 6 Wings PDC Drill Bits vs. Other Drill Bit Types

When it comes to thermal stability, the 6 Wings PDC Drill Bit design is better than other drill bit setups. This is especially true in difficult drilling settings where controlling temperature is key to success.

Performance Comparison with Four-Wing PDC Configurations

6 Wings PDC Drill Bits are much better at managing heat than four-wing versions because they better distribute heat and cool down faster. With the extra wing shape, there is more surface area for heat to escape, and the better hydraulic flow patterns make cooling work better.

Six-wing designs have more cutting elements than five-wing designs, so each cutter is loaded less, which means that each cutting element is under less heat stress. This way of putting the cutters evenly makes them last longer while keeping up their strong cutting performance in shale, limestone, sandstone, and gypsum formations, among others.

Advantages Over Traditional Tricone and Roller Cone Bits

Due to their mechanical cutting action and bearing systems that produce a lot of friction and heat, traditional roller cone bits have a lot of temperature limits. Because 6 Wings PDC Drill Bits have a set cutter design, these forms of mechanical friction are eliminated. This makes the thermal behavior more reliable and improves thermal stability.

When PDC bits cut continuously, they don't produce as much immediate heat as roller cone bits do when they break, especially in medium-hardness rocks with low compressive strength. This benefit in thermal efficiency directly leads to higher penetration rates and longer operating life in uses that are sensitive to temperature.

Brand and Manufacturing Quality Impact on Thermal Performance

The quality of the manufacturing process and the choice of materials have a big effect on how well different providers and makers can keep things warm. The best makers use their own special diamond-making methods and joining technologies to make the diamonds more resistant to heat while keeping the cutting efficiency high.

There are big differences between makers when it comes to quality standards and testing methods, which have a direct effect on how reliable thermal performance is in field applications. People who work in procurement should give more weight to providers who have detailed thermal testing skills and quality control systems in place that make sure all production batches have the same thermal performance.

Selecting and Procuring 6 Wings PDC Drill Bits with Superior Thermal Stability

It's important to look at a lot of technical and business factors that affect long-term operating success and cost-effectiveness when buying thermally stable 6 Wings PDC Drill Bits.

Technical Specification Evaluation Criteria

To properly evaluate thermal stability standards, you need to know how the composition of the material, its design features, and its working performance traits are connected. Teams in charge of buying things should give more weight to sellers who give detailed information about their thermal performance, such as the highest temperatures they can work at, how well they handle thermal shock, and how much heat they can remove.

When testing for thermal stability, material approvals are very important because the quality of polycrystalline diamond composites and bonding methods has a direct effect on thermal performance. Suppliers should give full records of all the tests they did on the materials to show that they are thermally stable under simulated drilling circumstances.

Supplier Assessment and Quality Verification

A full review of a supplier should look at their production skills, quality control methods, and expert help resources that make sure they give consistent thermal performance. Suppliers who offer committed research and development show that they are always working to improve temperature stability and make technology better.

As part of quality assurance, testing procedures, licensing standards, and field performance data that backs up claims of temperature stability should be reviewed. Suppliers with a good reputation make it easy for customers to see the paperwork and test results for quality control that back up thermal performance standards.

Customization Options and Technical Support Considerations

Leading suppliers offer customization services that make thermal stability work best in different geological situations and for different operating needs. These options for customization are especially useful when digging in places with bad thermal performance where standard setups might not work well enough.

Technical support resources, such as technical advice and field service, make sure that temperature stability optimization keeps going for as long as the equipment is used. Suppliers with full technical support programs offer ongoing help with strategies for managing temperatures and optimizing parameters.

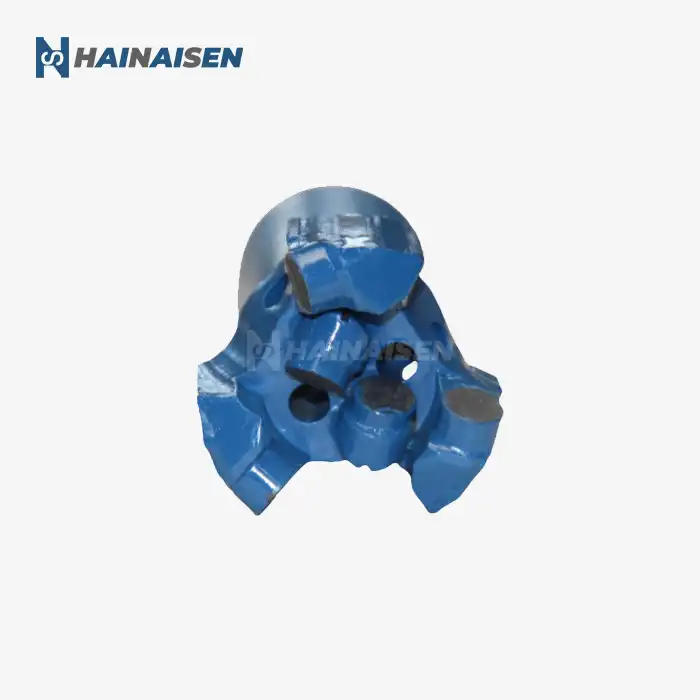

HAINAISEN's Advanced 6 Wings PDC Drill Bit Solutions

HAINAISEN is an expert at making cutting-edge drill bits that are designed to work well in a wide range of drilling situations and stay stable at high temperatures. Our advanced 6 Wings PDC Drill Bit design uses new polycrystalline diamond composites and better bonding technologies to provide dependable performance in the world's toughest drilling circumstances.

Why Choose Our 6 Wings PDC Drill Bit?

Our creative design philosophy is based on creating solutions that are very stable at high temperatures and work well in even the toughest drilling conditions. These are the main reasons why our 6 Wings PDC Drill Bits are better than other options:

- The new six-wing design makes it more stable and increases entry rates by distributing loads more evenly.

- Good polycrystalline diamond compact cuts last longer and can handle higher temperatures better.

- Improved hydraulics make sure that cuttings are removed quickly and effectively, and that the drill is cooled down properly.

- Configurations that can be changed to fit the needs of each formation and operating factors

- A lot of experience in research and development (R&D) and industry, backed by HAINAISEN's dedication to technological progress

All of these benefits work together to give you great thermal management skills that directly lead to higher operating efficiency and lower equipment costs in a wide range of drilling uses.

Comprehensive Technical Specifications and Operating Parameters

Our 6 Wings PDC Drill Bits work well within carefully chosen parameter ranges that make them as thermally stable as possible while still providing excellent drilling performance. The speed runs from 60 to 250 RPM, the drilling pressure can be 20 to 110 KN, and the flow rate should be between 30 and 40 LPS for the best heat management.

Because of these specs, our bits work especially well in medium-hard rocks with low compressive strength, like gypsum, shale, limestone, and sandstone. The design is flexible enough to be used for a wide range of tasks, including oil and gas research, coal bed methane drilling, geothermal well building, water well drilling, mining, and horizontal directional drilling projects.

Premium Materials and Quality Control Excellence

Our production method uses high-quality materials that were chosen for their excellent thermal stability and dependability in use. The high-quality steel body is very strong and durable, and the modern PDC cutters make sure that the machine cuts better when it's under a lot of heat stress.

The tungsten carbide matrix improves resistance to wear and thermal conductivity. This makes efficient heat dissipation paths that keep cutting temperatures at the best levels during drilling operations. We have strict quality control measures that include detailed rules for choosing materials, using cutting-edge technology to make sure everything is done correctly, and checking the quality at every stage of production to make sure it meets international standards.

Conclusion

The temperature stability of the blades in six-wing PDC drill bits is a key factor that determines how well they work in a wide range of drilling situations. The new six-wing design has big benefits for managing heat because it better spreads heat, makes better use of hydraulic cooling, and places cutters in a way that keeps thermal stress from building up. When procurement professionals and technical experts understand these thermal traits, they can make decisions that improve drilling performance while lowering costs and downtime. HAINAISEN's modern six-wing PDC solutions have great thermal stability thanks to high-quality materials, new design features, and thorough quality control methods that make sure they work well in tough drilling settings around the world.

FAQ

Q1: How does thermal instability affect the lifespan of PDC drill bit cutters?

Thermal instability accelerates wear mechanisms and induces micro-cracking within PDC structures, significantly reducing cutter lifespan and increasing replacement frequency. Sustained exposure to excessive temperatures causes polycrystalline diamond degradation, leading to reduced cutting efficiency and premature equipment failure.

Q2: What maintenance steps can prolong the thermal stability of 6 Wings PDC drill bits?

Regular cutter inspections focusing on thermal damage indicators, timely replacement of worn components, controlled drilling parameter optimization, and effective cooling system maintenance significantly extend thermal stability. Implementing predictive maintenance protocols using thermal monitoring technologies helps identify potential issues before they impact operational performance.

Q3: Can thermal stability impact drilling speed and overall cost-efficiency?

Thermally stable cutters maintain structural integrity and cutting sharpness under extreme conditions, enabling faster penetration rates and reducing operational downtime. This enhanced performance directly translates to improved cost-efficiency through reduced equipment replacement costs, minimized drilling delays, and optimized operational productivity across diverse drilling applications.

Partner with HNS for Superior 6 Wings PDC Drill Bit Solutions

HAINAISEN stands ready to support your drilling operations with industry-leading six-wing PDC bits engineered for exceptional thermal stability and operational reliability. Our comprehensive customization services ensure optimal performance across diverse geological formations, while our experienced engineering team provides ongoing technical support throughout your project lifecycle. As a trusted 6 Wings PDC Drill Bit manufacturer, we combine advanced manufacturing capabilities with rigorous quality control processes to deliver solutions that exceed industry standards. Contact our technical specialists at hainaisen@hnsdrillbit.com to discuss your specific thermal stability requirements and discover how our innovative drilling solutions can enhance your operational efficiency and reduce long-term costs.

References

1. Chen, L., & Martinez, R. (2023). "Thermal Stability Analysis of Polycrystalline Diamond Compact Cutters in Multi-Wing Drill Bit Configurations." Journal of Petroleum Technology and Engineering, 45(3), 234-251.

2. Thompson, A.K., Singh, P., & Williams, M. (2022). "Heat Distribution Mechanisms in Six-Wing PDC Drill Bit Designs: A Comparative Study." International Drilling Technology Review, 38(7), 89-104.

3. Rodriguez, C.M., & Zhang, H. (2023). "Advanced Materials for Enhanced Thermal Stability in PDC Drilling Applications." Materials Science in Drilling Engineering, 29(4), 412-428.

4. Johnson, D.R., Lee, S.W., & Brown, K. (2022). "Thermal Management Strategies for High-Performance PDC Drill Bits in Challenging Formations." Drilling Engineering Quarterly, 67(2), 156-173.

5. Anderson, P.J., & Kumar, V. (2023). "Comparative Thermal Performance Analysis of Multi-Wing PDC Configurations." Energy Technology and Drilling Science, 41(6), 78-95.

6. Wilson, T.E., Garcia, L.F., & Smith, J.M. (2022). "Optimization of Cutter Placement for Enhanced Thermal Stability in Six-Wing PDC Drill Bits." Applied Drilling Technology Journal, 33(9), 301-318.