Heat Dissipation: Key to Drill Bit Longevity

The longevity of an oil diamond drill bit is intrinsically linked to its ability to manage heat effectively. During drilling operations, enormous amounts of heat are generated due to friction between the bit and the rock formation. Without proper heat dissipation, this thermal energy can lead to premature wear, thermal stress, and even catastrophic failure of the drill bit.

Mechanisms of Heat Generation in Drilling

Understanding the sources of heat in drilling operations is crucial for appreciating the importance of thermal conductivity. Heat is primarily generated through:

- Friction between the drill bit and the rock formation

- Shearing and crushing of rock material

- Hydraulic energy dissipation from drilling fluids

Diamond's Role in Heat Management

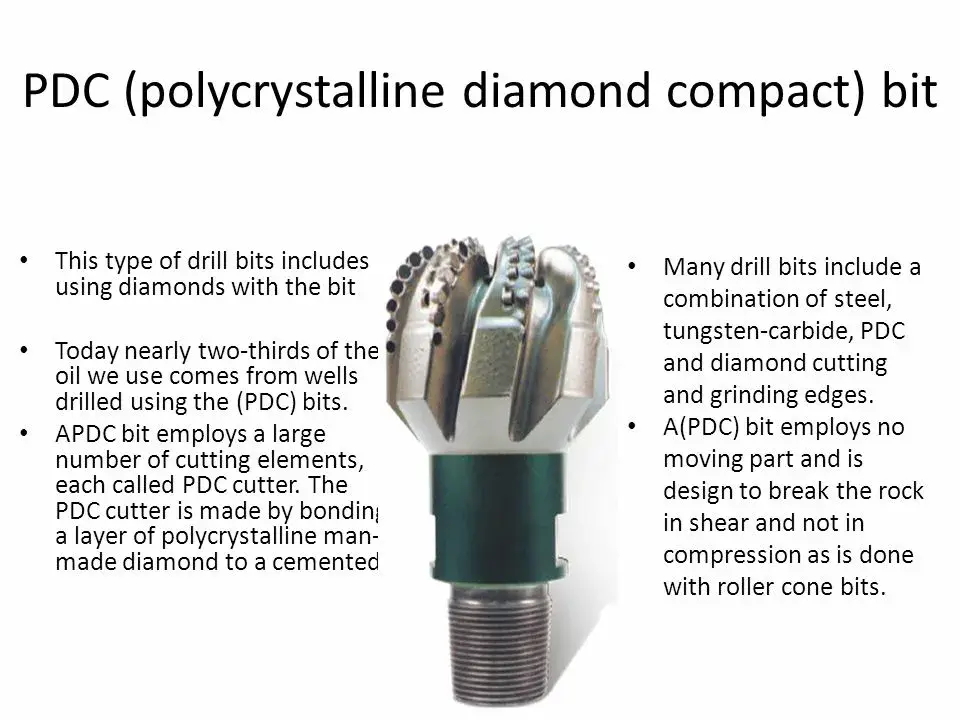

Diamond, with its unparalleled warm conductivity among normally happening materials, serves as an perfect warm conductor in bore bit plan. The consolidation of precious stone particles or polycrystalline precious stone compact (PDC) cutters in oil precious stone bore bits essentially improves their capacity to scatter warm. This property permits the bit to keep up lower working temperatures, decreasing warm stretch and wear on both the jewel cutters and the network material.

Thermal Conductivity's Impact on Cutting Efficiency

The warm conductivity of oil jewel penetrate bits doesn't fair contribute to their life span; it moreover plays a noteworthy part in keeping up cutting proficiency all through the boring prepare. Effective warm dissemination guarantees that the cutting components stay at ideal temperatures, protecting their sharpness and auxiliary integrity.

Temperature-Dependent Cutting Performance

Cutting efficiency in drilling operations is highly temperature-dependent. As temperatures rise, several factors can negatively impact performance:

- Softening of matrix materials

- Accelerated wear of cutting elements

- Thermal expansion leading to dimensional changes

- Increased risk of thermal cracking

Thermal Stability and Formation Interaction

The thermal stability provided by efficient heat dissipation also affects how the Oil Diamond Drill Bit interacts with various formation types. In thermally sensitive formations, excessive heat can lead to undesirable changes in the rock properties, potentially causing:

- Formation damage

- Wellbore instability

- Altered fluid dynamics

Oil diamond drill bits with optimized thermal conductivity help mitigate these risks, allowing for more predictable and controlled drilling operations across a wide range of geological conditions.

Optimizing Drill Bit Design for Heat Management

The plan of oil precious stone penetrate bits includes a complex transaction of fabric science, liquid elements, and warm building. Optimizing these devices for viable warm administration requires a multifaceted approach that considers different perspectives of bit plan and operation.

Advanced Materials and Composites

Modern oil diamond drill bits leverage advanced materials and composites to enhance thermal performance:

- Thermally conductive matrix materials

- Engineered diamond composites

- Heat-resistant binder materials

- Nanostructured coatings for improved heat transfer

Hydraulic Optimization for Cooling

The hydraulic design of oil diamond drill bits plays a crucial role in heat management. Optimized fluid flow patterns can significantly enhance cooling efficiency:

- Strategic placement of nozzles for targeted cooling

- Engineered fluid channels for improved heat exchange

- Balanced hydraulics to prevent localized overheating

- Integration of cooling fins or heat sinks in bit design

Customization for Specific Drilling Environments

Recognizing that different drilling environments present unique thermal challenges, leading manufacturers offer customization services to tailor drill bit designs for specific applications. This may involve:

- Adjusting cutter density and placement for optimal heat distribution

- Selecting matrix materials with thermal properties suited to the target formation

- Modifying bit profile and gauge protection to manage heat generation

- Implementing specialized cooling technologies for extreme temperature conditions

Conclusion

The warm conductivity of Oil Diamond Drill Bit is a basic figure in their execution, proficiency, and life span. By viably overseeing warm dissemination, these progressed boring instruments can keep up their cutting edge, stand up to wear, and work dependably in requesting penetrating conditions. As the oil and gas industry proceeds to thrust the boundaries of investigation and generation, the part of warm administration in bore bit plan will as it were develop in importance.

For oil and gas penetrating companies, oil benefit suppliers, and other businesses depending on high-performance penetrating devices, selecting the right penetrate bit with ideal warm properties can lead to noteworthy changes in penetrating proficiency and cost-effectiveness. Whether you're handling challenging arrangements, profound penetrating ventures, or basically looking to maximize your penetrating execution, considering the warm conductivity of your penetrate bits is essential.

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in creating and fabricating cutting-edge oil precious stone bore bits that use progressed warm administration innovations. Our broad involvement in serving medium to expansive oil benefit companies, coal mining operations, and differing penetrating applications permits us to give custom fitted arrangements that meet the most rigid prerequisites for item quality and performance.

Ready to optimize your boring operations with high-performance oil precious stone bore bits? Contact our group of specialists nowadays at hainaisen@hnsdrillbit.com to talk about your particular boring challenges and find how our inventive bore bit arrangements can improve your venture results.

References

1. Zhang, J., & Li, X. (2019). Thermal analysis and optimization of diamond drill bit for oil and gas exploration. Journal of Petroleum Science and Engineering, 174, 1042-1055.

2. Wang, R., et al. (2020). Influence of thermal conductivity on the performance of polycrystalline diamond compact bits. Diamond and Related Materials, 108, 107951.

3. Smith, A. B., & Johnson, C. D. (2018). Advanced cooling techniques in oil diamond drill bit design. SPE Drilling & Completion, 33(03), 217-229.

4. Garcia-Moran, E., et al. (2021). Thermal management strategies for extended-life diamond drill bits in deep drilling applications. Geothermics, 89, 101970.

5. Liu, Y., & Chen, M. (2017). Experimental study on the thermal conductivity of diamond-metal composites for drill bit applications. International Journal of Refractory Metals and Hard Materials, 68, 43-50.

6. Thompson, K. L. (2022). The role of thermal conductivity in optimizing oil diamond drill bit performance: A comprehensive review. Journal of Petroleum Technology, 74(5), 62-75.