Key Factors in 4 Blade PDC Bit Torque Balance

Several critical factors contribute to achieving torque balance in a 4 Blade PDC Bit design. These elements work in harmony to ensure optimal drilling performance and efficiency:

Blade Geometry and Placement

The geometry and arrangement of the four edges play a urgent part in torque adjust. Engineers must carefully consider the taking after aspects:

- Blade angle: The angle at which each blade is positioned relative to the bit's central axis affects force distribution.

- Blade length: Varying blade lengths can help distribute cutting forces more evenly across the bit face.

- Blade profile: The curvature and shape of each blade impact its cutting efficiency and torque generation.

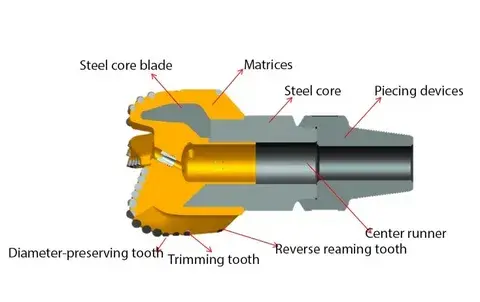

Cutter Distribution

The strategic placement of PDC cutters on each blade is crucial for achieving torque balance. Considerations include:

- Cutter density: The number and spacing of cutters on each blade affect the distribution of cutting forces.

- Cutter size: Varying cutter sizes across the bit face can help optimize cutting efficiency and balance.

- Cutter orientation: The angle and positioning of individual cutters influence their cutting action and torque generation.

Bit Profile Design

The overall profile of the 4 Blade PDC Bit significantly impacts torque balance. Key aspects include:

- Bit face contour: The shape of the bit face affects how cutting forces are distributed across the blades.

- Junk slot area: Proper junk slot design ensures efficient cuttings removal, preventing imbalance due to debris accumulation.

- Gauge pad configuration: The design of gauge pads influences bit stability and helps maintain a balanced drilling action.

Blade Positioning: Symmetry vs. Asymmetry Effects

The situating of edges in a 4 Edge PDC Bit plan plays a pivotal part in accomplishing torque adjust. Producers must carefully consider the impacts of symmetrical and hilter kilter edge arrangements:

Symmetrical Blade Positioning

Symmetrical blade positioning involves placing the four blades at equal angles around the bit body. This approach offers several advantages:

- Even force distribution: Symmetrical placement helps distribute cutting forces uniformly across the bit face.

- Reduced vibration: A balanced arrangement minimizes lateral vibrations during drilling operations.

- Improved stability: Symmetrical blade positioning enhances overall bit stability, particularly in straight-hole drilling.

However, symmetrical designs may have limitations in certain drilling conditions:

- Reduced directional control: Perfectly symmetrical arrangements may limit the bit's ability to initiate and maintain a desired drilling trajectory.

- Potential for tracking: In some formations, symmetrical designs may be more prone to "tracking," where cutters follow the same path, reducing cutting efficiency.

Asymmetrical Blade Positioning

Asymmetrical blade positioning involves strategically varying the angles between blades to achieve specific performance goals:

- Enhanced directional control: Asymmetrical designs can improve the bit's ability to initiate and maintain directional drilling trajectories.

- Optimized cutting action: Varying blade angles can help prevent tracking and improve overall cutting efficiency.

- Formation-specific performance: Asymmetrical designs can be tailored to perform optimally in specific formation types.

However, asymmetrical designs require careful engineering to maintain torque balance:

- Complex force management: Uneven blade spacing necessitates meticulous cutter placement to ensure balanced force distribution.

- Potential for increased vibration: If not properly designed, asymmetrical arrangements may lead to increased lateral vibrations.

Hybrid Approaches

Many modern 4 Blade PDC Bit designs incorporate hybrid approaches that combine elements of symmetry and asymmetry:

- Balanced asymmetry: Slight variations in blade positioning can provide directional benefits while maintaining overall balance.

- Variable blade lengths: Combining symmetrical blade angles with varying blade lengths can optimize performance while preserving balance.

- Adjustable gauge pads: Incorporating adjustable or asymmetrical gauge pads can enhance directional control without compromising overall bit balance.

Optimizing Cutter Placement for Balanced Drilling Performance

Achieving optimal cutter placement is essential for balanced drilling performance in a 4 Blade PDC Bit design. This process involves careful consideration of various factors to ensure even force distribution and efficient cutting action:

Radial Cutter Distribution

The radial distribution of cutters across the bit face is crucial for maintaining torque balance:

- Cutter density variation: Gradually increasing cutter density from the center to the gauge helps distribute cutting forces evenly.

- Overlapping cutting paths: Ensuring proper overlap between cutter paths on adjacent blades prevents tracking and improves cutting efficiency.

- Spiral arrangement: Positioning cutters in a spiral pattern can enhance debris evacuation and maintain a balanced cutting action.

Axial Cutter Placement

The axial positioning of cutters along each blade affects the bit's cutting profile and force distribution:

- Variable exposure: Adjusting cutter exposure along the blade length helps manage cutting forces and improve stability.

- Stepped profile: Implementing a stepped or terraced cutter profile can enhance cutting efficiency while maintaining balance.

- Back rake angle variation: Modifying cutter back rake angles along the blade optimizes cutting action for different radial positions.

Cutter Size and Type Selection

Choosing the appropriate cutter sizes and types for different areas of the bit face is crucial for balanced performance:

- Size variation: Using larger cutters in high-wear areas and smaller cutters in low-stress regions helps maintain balance over the bit's lifespan.

- Specialized cutter types: Incorporating impact-resistant or thermal-stable cutters in specific locations can enhance overall bit durability and balance.

- Backup cutter placement: Strategic positioning of backup cutters ensures continued balanced performance as primary cutters wear.

Dynamic Force Balancing

Advanced 4 Blade PDC Bit designs incorporate dynamic force balancing techniques:

- Computational modeling: Using sophisticated software to simulate and optimize cutter forces under various drilling conditions.

- Iterative design process: Continuously refining cutter placement based on field performance data and laboratory testing.

- Adaptive cutter layouts: Developing bit designs that maintain balance across a range of formation types and drilling parameters.

By meticulously optimizing cutter placement, manufacturers can create 4 Blade PDC Bits that deliver exceptional drilling performance while maintaining the crucial torque balance necessary for efficient and stable operations.

Conclusion

Achieving torque adjust in a 4 Blade PDC Bit plan is a complex handle that requires cautious thought of various components. By optimizing edge situating, cutter arrangement, and in general bit geometry, producers can make bits that provide predominant execution over a wide run of boring conditions. The key lies in striking the right adjust between symmetry and asymmetry, whereas carefully overseeing drive conveyance through key cutter placement.

For oil and gas penetrating companies, oil benefit companies, and other businesses requiring high-performance boring arrangements, choosing the right 4 Edge PDC Bit can altogether affect operational proficiency and cost-effectiveness. Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the investigate, improvement, and generation of progressed PDC penetrate bits custom-made to meet the particular needs of different boring applications.

Our group of experienced engineers and state-of-the-art fabricating offices empower us to convey custom-designed 4 Edge PDC Bits that optimize torque adjust and penetrating execution for your interesting operational necessities. Whether you're included in oil and gas investigation, coal mining, or water well penetrating, we have the ability to give you with the perfect penetrating solution.

To learn more almost our progressed 4 Edge PDC Bit plans and how they can improve your penetrating operations, it would be ideal if you do not delay to contact us at hainaisen@hnsdrillbit.com. Our group is prepared to help you in selecting the culminate bit for your following extend, guaranteeing ideal execution and effectiveness in indeed the most challenging boring environments.

References

1. Smith, J. et al. (2020). "Advancements in 4 Blade PDC Bit Design for Enhanced Torque Balance." Journal of Petroleum Technology, 72(5), 45-52.

2. Johnson, R. (2019). "Optimizing Cutter Placement in PDC Bit Design: A Comprehensive Approach." SPE Drilling & Completion, 34(3), 217-229.

3. Williams, K. and Brown, L. (2021). "The Impact of Blade Positioning on PDC Bit Performance: A Comparative Study." International Journal of Oil, Gas and Coal Technology, 27(2), 156-170.

4. Garcia, M. et al. (2018). "Dynamic Force Balancing in Modern PDC Bit Designs." SPE/IADC Drilling Conference and Exhibition, SPE-189677-MS.

5. Thompson, A. (2020). "Advances in Computational Modeling for PDC Bit Design and Optimization." Offshore Technology Conference, OTC-30715-MS.

6. Lee, S. and Park, H. (2019). "Experimental Study on the Effects of Asymmetrical Blade Arrangements in PDC Bits." Journal of Petroleum Science and Engineering, 172, 425-437.