What affects thermal stability under downhole pressure?

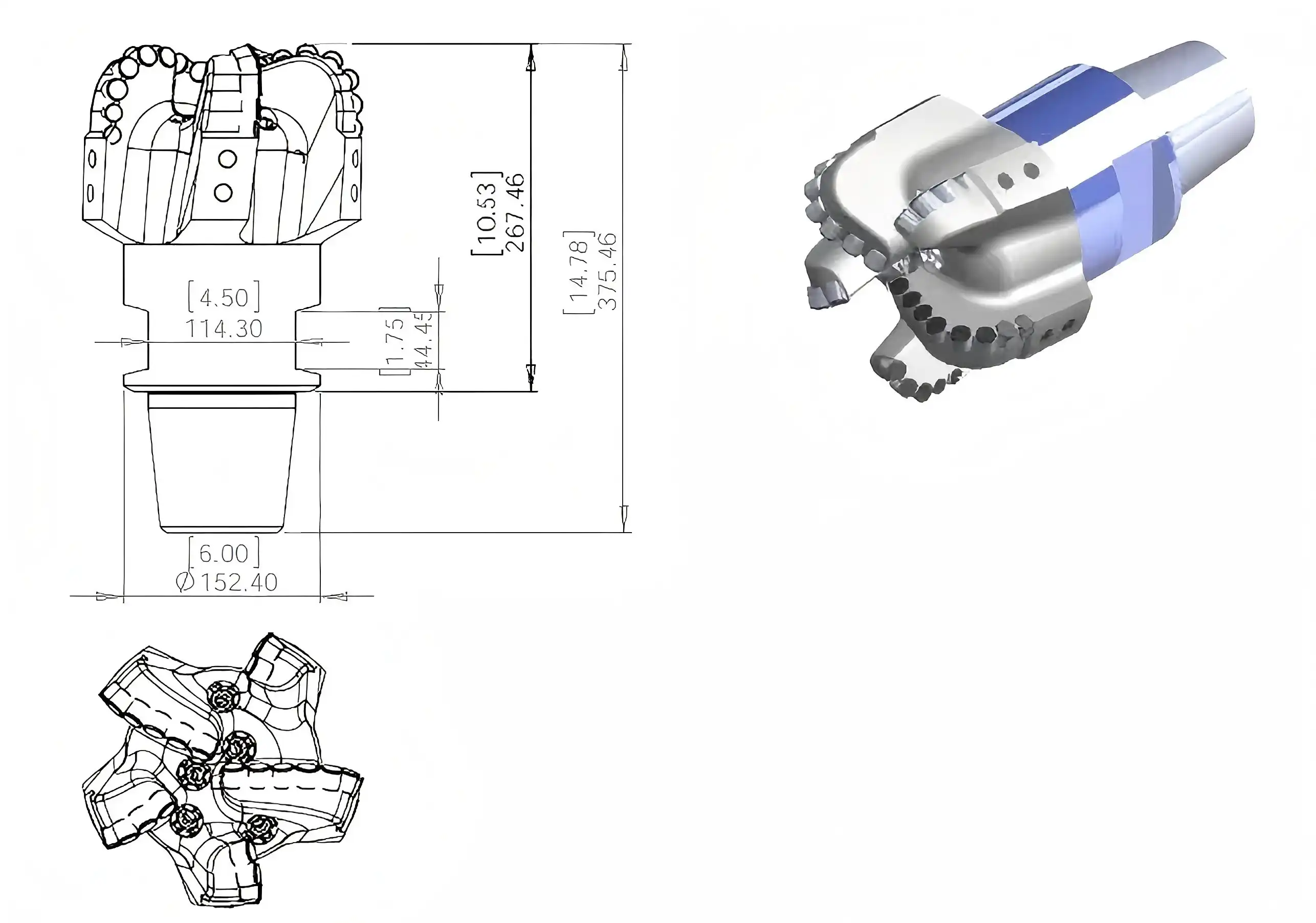

There are many things that affect how thermally stable 5 Blade Matrix Body PDC Drill Bits are under downhole pressure. Each of these things is very important to the bit's total performance and durability. Both manufacturers and operators need to know about these factors in order to build and use bits most effectively in difficult drilling conditions.

Material composition and quality

The materials that are used to make PDC drill bits have a big effect on how stable they are at high temperatures. High-grade steel matrix bodies are stronger and better at transferring heat, and modern PDC cutters with the right amount of diamond grain size and distribution are cooler. It's also important how well the diamond table and tungsten carbide base stick together, since that affects how well the cutter can handle thermal stresses without coming apart.

Bit design and cutter layout

The geometric configuration of the bit, including the number and placement of blades, plays a vital role in thermal stability. A well-designed 5 Blade Matrix Body PDC Drill Bit allows for efficient heat distribution and cooling. The arrangement of cutters on the bit face influences how heat is generated and dissipated during drilling. Optimized cutter positioning can reduce friction and heat buildup, enhancing overall thermal stability.

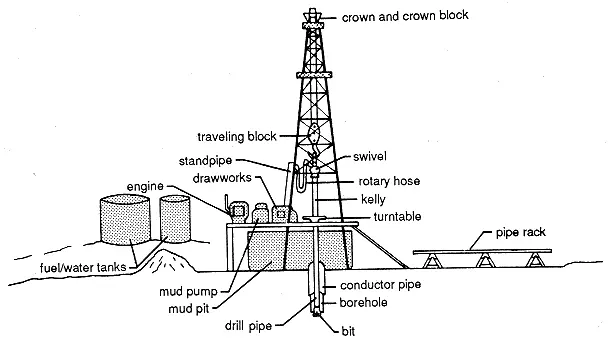

Hydraulic design and cooling efficiency

Keeping the temperature stable under pressure requires hydraulics that work well. How well the drilling fluid can cool the cutters and remove heat from the cutting zone depends on how the bit's tip is set up and how the fluid flows. The right hydraulic design not only helps get rid of heat, but it also makes cleaning holes better, which lowers friction and heat production.

Formation characteristics

Thermal stability is affected by the rock being drilled in a big way. Harder formations usually make more heat because they have more friction, while abrasive formations can make the cuts wear out faster, which could cause heat to build up in one spot. It is very important to know the properties of the target formation in order to choose the right bit design and operating settings that will keep the temperature stable.

How does pressure influence heat tolerance of 5-blade PDC bits?

Tensile strength of 5 Blade Matrix Body PDC Drill Bits is affected by pressure, which in turn impacts their ability to handle heat. This has various effects on their performance and durability. Multiple processes can either improve or decrease the bit's ability to withstand high temperatures. The relationship between pressure and thermal stability is complicated.

Pressure-induced stress on bit components

All parts of the drill bit are put under a lot of force by high downhole pressures. These pressures can change the thermal properties of materials, which could change how well they conduct heat and how much they expand. In some cases, adding more pressure can make PDC cuts more thermally stable by improving the bonding between diamonds in the polycrystalline structure. But too much pressure can also cause tiny cracks or deformations, which could make the bit less resistant to heat overall.

Influence on drilling fluid properties

The qualities of drilling fluids are greatly changed by pressure. These fluids are very important for keeping the drill bit cool and smooth. The viscosity and density of the drilling fluid change as the pressure rises, which could affect how well it moves heat. Higher pressures may make it easier for the fluid to move heat away from the bit, but they may also make the fluid and bit surface rub against each other more, which creates more heat.

Pressure effects on formation behavior

The pressure environment influences how the formation behaves during drilling, which in turn affects the thermal load on the bit. Higher pressures can increase the plasticity of some rocks, potentially reducing the cutting efficiency and increasing friction. Conversely, in certain formations, increased pressure can lead to more brittle rock behavior, which may actually improve drilling efficiency and reduce heat generation.

Thermal expansion and contraction under pressure

The pressure environment impacts how materials in the drill bit expand and contract with temperature changes. Under high pressures, thermal expansion may be restricted, potentially leading to internal stresses within the bit components. This can affect the integrity of interfaces between different materials, such as the bond between the PDC cutter and the matrix body. Understanding and accounting for these pressure-induced thermal behaviors is crucial in designing bits that maintain their structural integrity under varying downhole conditions.

Thermal degradation mechanisms in matrix PDC under load

Understanding the thermal degradation mechanisms in 5 Blade Matrix Body PDC Drill Bits under load is crucial for improving their performance and longevity. These mechanisms are complex and often interrelated, involving both chemical and physical processes that can compromise the bit's integrity and cutting efficiency.

Graphitization of diamond

One of the primary thermal degradation mechanisms in PDC cutters is the graphitization of diamond. At elevated temperatures, especially under high pressure and in the presence of catalytic metals, the diamond structure can begin to transform into graphite. This process weakens the cutter, reducing its wear resistance and cutting ability. The rate of graphitization increases with temperature, making it a critical concern in high-temperature drilling environments.

Thermal fatigue and cracking

Repeated cycles of heating and cooling, common in drilling operations, can lead to thermal fatigue in both the matrix body and PDC cutters. This cyclical stress can cause micro-cracks to form and propagate, potentially leading to cutter fracture or matrix body failure. The different thermal expansion rates of various materials used in the bit construction can exacerbate this issue, creating internal stresses at material interfaces.

Oxidation and chemical degradation

Both the diamond table and the matrix body can oxidize at high temperatures, especially when air or reactive drilling fluids are present. This chemical breakdown can make the materials less strong, which can speed up wear and tear and make them less stable at high temperatures. For example, the matrix material can rust easily, which can make it less able to hold and support the PDC cuts.

Diffusion and migration of catalytic metals

Small amounts of catalytic metals are often found in PDC cutters because they are used in the making process. When these metals are heated and pressed to high levels, they can move through the diamond structure and weaken the bonds between the crystals. This diffusion process can make the cutter less stable at high temperatures and less resistant to wear, especially where the diamond table meets the material.

Thermal softening of binder materials

Most PDC drill bits have binder materials in the matrix body that keep the tungsten carbide pieces together. When these binders are heated up, they can soften. This makes the matrix less strong and less resistant to wear. This can cause the matrix material to wear away faster, which could affect the bit's hydraulics and cutter holding.

Conclusion

How stable the 5 Blade Matrix Body PDC is at high temperatures Putting pressure on drill bits is an important part of how well they work in tough cutting conditions. Engineers and users can make smart choices about bit design and use if they know what affects thermal stability, how pressure affects heat tolerance, and how thermal degradation works. To push the limits of drilling technology and get better results in difficult geological formations, this information is important.

For oil and gas companies, coal mining operations, and water well drilling teams looking to enhance their drilling performance, Shaanxi Hainaisen Petroleum Technology Co., Ltd. offers cutting-edge 5 Blade Matrix Body PDC Drill Bits designed to excel in high-pressure, high-temperature environments. Our advanced manufacturing processes and custom design capabilities ensure that each bit is optimized for your specific drilling conditions. Whether you're a large oil service company requiring top-tier performance or a smaller operation seeking cost-effective solutions without compromising on quality, we have the expertise to meet your needs. Contact our team of experts today at hainaisen@hnsdrillbit.com to discuss how our innovative drill bits can improve your drilling efficiency and reduce overall project costs.

References

1. Zhang, J., & Li, X. (2020). Thermal stability analysis of PDC drill bits under high-pressure high-temperature conditions. Journal of Petroleum Science and Engineering, 185, 106633.

2. Wang, H., & Swenson, D. (2019). Experimental study on the thermal degradation of polycrystalline diamond compact cutters under simulated downhole conditions. Wear, 426-427, 1542-1551.

3. Yahiaoui, M., et al. (2021). Influence of pressure on the thermal stability of matrix-body PDC drill bits: A numerical investigation. International Journal of Rock Mechanics and Mining Sciences, 138, 104630.

4. Garcia-Moran, E., & Hernandez, J. (2018). Advanced thermal management strategies for PDC drill bits in high-temperature applications. SPE Drilling & Completion, 33(03), 227-239.

5. Chen, P., & Gao, D. (2022). Mechanisms of thermal degradation in matrix-body PDC bits under combined pressure and temperature loads. Tribology International, 166, 107332.

6. Smith, R., & Johnson, K. (2020). Optimization of 5-blade PDC bit designs for improved thermal stability in deep drilling operations. SPE/IADC Drilling Conference and Exhibition, Society of Petroleum Engineers.