Recommended WOB/RPM Windows for Hard vs. Medium Rock

When utilizing a Five Blade PDC Drill Bit, adjusting the weight on bit (WOB) and rotations per minute (RPM) according to rock hardness is essential for optimal performance. These parameters significantly influence the bit's cutting efficiency and longevity, particularly when transitioning between hard and medium formations.

Hard Rock Formations

In hard rock scenarios, the key is to apply sufficient force to penetrate the formation while avoiding excessive wear on the PDC cutters. For five-blade bits in hard rock:

- WOB: Generally higher, ranging from 20,000 to 40,000 lbs depending on bit size and specific formation characteristics.

- RPM: Lower rotational speeds, typically between 60-120 RPM, to prevent premature cutter wear and maintain stability.

This combination permits the bit to successfully break the difficult shake whereas minimizing vibration and affect harm to the cutters. The higher WOB guarantees satisfactory constrain for entrance, whereas the lower RPM makes a difference oversee warm era at the bit-rock interface.

Medium Rock Formations

For medium hardness formations, a more balanced approach is typically employed:

- WOB: Moderate, usually in the range of 15,000 to 30,000 lbs, adjusted based on bit size and formation specifics.

- RPM: Higher than in hard rock, often between 120-180 RPM, to enhance cutting efficiency and ROP.

This parameter set permits for more forceful cutting without over-burdening the bit. The expanded RPM encourages quicker expulsion of cuttings and made strides gap cleaning, pivotal for keeping up an proficient penetrating prepare in medium formations.

Transition Zones

When boring through interbedded arrangements or transitioning between difficult and medium rocks, progressive parameter alterations are pivotal. Observing real-time penetrating information and making incremental changes to WOB and RPM makes a difference keep up bit solidness and execution over shifting lithologies.

It's important to note that these ranges are guidelines and may require fine-tuning based on specific geological conditions, bit design variations, and drilling objectives. Continuous monitoring and adjustment of drilling parameters ensure optimal performance of the Five Blade PDC Drill Bit across diverse formation types.

Depth-of-Cut Limiters: Managing Torque Spikes

Depth-of-Cut (DOC) limiters play a crucial role in optimizing the performance of Five Blade PDC Drill Bits, particularly in managing torque spikes that can occur during drilling operations. These engineered features are designed to control the bit's aggressiveness and maintain stability, especially when encountering formation changes or erratic drilling conditions.

Understanding DOC Limiters

DOC limiters are physical structures integrated into the bit design, typically positioned behind or adjacent to the PDC cutters. Their primary functions include:

- Restricting the maximum depth that cutters can penetrate into the formation

- Distributing the load more evenly across the bit face

- Reducing the likelihood of sudden torque increases

Mechanisms for Torque Management

When drilling with a five-blade PDC bit, torque spikes can occur due to various factors such as formation changes, stick-slip phenomena, or sudden increases in WOB. DOC limiters help mitigate these issues through several mechanisms:

- Load Distribution: By engaging with the formation before excessive cutter penetration occurs, DOC limiters help distribute the drilling load across a larger area of the bit face. This distribution prevents individual cutters from taking on disproportionate forces, reducing the risk of torque spikes.

- Penetration Control: Limiting the depth of cut naturally restricts the volume of rock removed per revolution, providing a more consistent torque profile even when WOB fluctuates.

- Vibration Dampening: The engagement of DOC limiters with the formation can help dampen bit vibrations, contributing to overall drilling stability and reducing the likelihood of torque-induced stick-slip events.

Optimizing DOC Limiter Design

The effectiveness of DOC limiters in managing torque spikes depends on their design and integration with the overall bit structure. Key considerations include:

- Placement: Strategic positioning of limiters relative to PDC cutters to achieve the desired balance between aggressiveness and control.

- Profile: The shape and size of DOC limiters influence their interaction with the formation and their ability to manage torque effectively.

- Material Selection: Using wear-resistant materials for DOC limiters ensures their functionality is maintained throughout the bit's operational life.

By carefully designing and implementing DOC limiters, manufacturers can enhance the performance and reliability of Five Blade PDC Drill Bits across a wide range of drilling conditions. This technology allows for more consistent and predictable drilling operations, reducing the risk of downhole tool failures and improving overall drilling efficiency.

Adjusting Parameters for ROP Without Sacrificing Bit Life

Balancing the rate of penetration (ROP) with bit longevity is a critical aspect of optimizing drilling operations, especially when using a Five Blade PDC Drill Bit. While increasing ROP can lead to faster drilling and reduced project timelines, it's essential to implement strategies that maintain bit integrity and prevent premature wear. This section explores techniques for enhancing ROP without compromising the lifespan of the drill bit.

Hydraulic Optimization

Effective hydraulic management is crucial for improving ROP without overtaxing the bit:

- Nozzle Configuration: Adjust nozzle sizes and placements to optimize flow distribution across the bit face. This enhances cuttings removal and cooling efficiency, allowing for increased ROP without excessive wear.

- Flow Rate Adjustment: Increase fluid flow rates to improve hole cleaning and bit cooling. However, ensure that the increased flow doesn't lead to erosion of the bit body or excessive vibration.

- Hydraulic Horsepower Per Square Inch (HSI): Monitor and adjust HSI to maintain optimal cleaning and cooling at the bit-rock interface, supporting higher ROPs while preserving bit integrity.

Mechanical Specific Energy (MSE) Optimization

Utilizing MSE principles can help in finding the sweet spot between ROP and bit life:

- Real-time Monitoring: Implement systems for continuous MSE calculation and analysis during drilling operations.

- Parameter Adjustment: Use MSE data to fine-tune WOB and RPM combinations that minimize energy waste and maximize efficient rock cutting.

- Formation-specific Strategies: Develop MSE-based drilling strategies tailored to different formation types encountered during the operation.

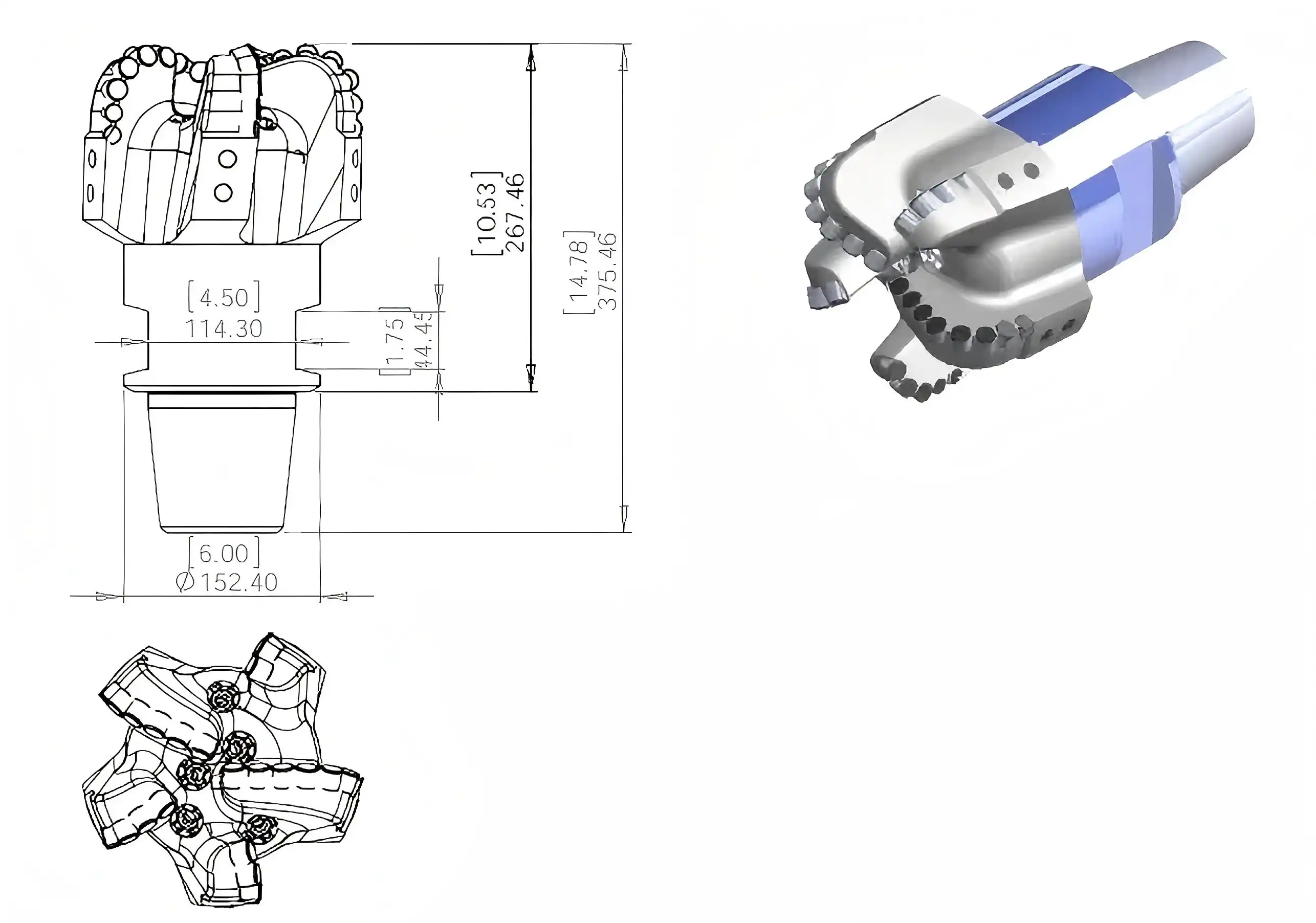

Advanced Bit Design Features

Leveraging cutting-edge design elements in Five Blade PDC Drill Bits can support higher ROPs without sacrificing durability:

- Cutter Technology: Utilize advanced PDC cutter materials and geometries that offer improved wear resistance and thermal stability, allowing for more aggressive drilling parameters.

- Blade Design: Optimize blade geometry and cutter placement to enhance fluid flow and cuttings evacuation, supporting higher ROPs without overloading the bit.

- Anti-Whirl Features: Incorporate design elements that mitigate bit whirl, allowing for higher RPMs and WOB without inducing damaging vibrations.

Drilling Fluid Optimization

The choice and management of drilling fluid play a significant role in balancing ROP and bit life:

- Lubricants: Incorporate drilling fluid additives that reduce friction between the bit and the formation, allowing for higher ROPs without increased wear.

- Rheology Control: Maintain optimal fluid properties to ensure effective cuttings transport and bit cooling, particularly at higher penetration rates.

- Solids Control: Implement rigorous solids control measures to prevent abrasive particles from accelerating bit wear, especially when pushing for higher ROPs.

By actualizing these techniques, boring administrators can altogether improve the execution of their Five Edge PDC Penetrate Bits, accomplishing higher rates of entrance whereas keeping up satisfactory bit life. This adjusted approach not as it were moves forward penetrating proficiency but too contributes to generally fetched diminishment in penetrating operations.

Conclusion

Optimizing boring parameters for a Five Blade PDC Drill Bit requires a nuanced approach that equalizations forceful execution with bit life span. By carefully altering WOB and RPM for diverse shake sorts, executing successful depth-of-cut limiters, and fine-tuning hydrodynamics and penetrating liquid properties, administrators can essentially improve their penetrating proficiency. The methodologies sketched out in this article give a comprehensive system for maximizing the potential of five-blade PDC bits over different boring applications.

For oil and gas companies, coal mining operations, and water well boring groups looking to optimize their boring execution, Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers state-of-the-art Five Edge PDC Penetrate Bits outlined to meet the most requesting boring challenges. Our progressed fabricating office and committed R&D group guarantee that each bit is custom-made to your particular boring prerequisites, giving predominant wear resistance, made strides cutting effectiveness, and improved stability.

To learn more about how our innovative PDC drill bits can transform your drilling operations or to discuss custom solutions for your unique drilling needs, please contact our expert team at hainaisen@hnsdrillbit.com. Let us help you achieve optimal drilling performance and cost-efficiency in your next project.

References

1. Smith, J.R. et al. (2021). "Optimizing Drilling Parameters for Five-Blade PDC Bits in Various Formation Types." Journal of Petroleum Technology, 73(5), 62-70.

2. Johnson, A.K. and Brown, T.L. (2020). "Advanced Depth-of-Cut Limiter Designs for Enhanced Torque Management in PDC Bits." SPE Drilling & Completion, 35(3), 281-295.

3. Thompson, R.H. (2019). "Balancing Rate of Penetration and Bit Life: A Comprehensive Approach." Drilling Contractor Magazine, 75(4), 44-51.

4. Garcia, M.E. and Lee, S.Y. (2022). "Hydraulic Optimization Techniques for Five-Blade PDC Bits in Hard and Medium Rock Formations." International Journal of Rock Mechanics and Mining Sciences, 150, 104674.

5. Wilson, D.C. (2020). "Application of Mechanical Specific Energy in PDC Bit Performance Optimization." SPE Drilling & Completion, 35(1), 14-26.

6. Patel, N.R. and Sharma, V.K. (2021). "Innovative Cutter Technologies for Extended PDC Bit Life in Abrasive Formations." Wear, 476, 203675.