What Defines Drill Bit Dullness in Oil Well Operations?

Drill bit dullness is a critical factor that can significantly impact the efficiency and effectiveness of oil well operations. Understanding the signs and causes of dullness is essential for maintaining optimal drilling performance. Here are key indicators that define drill bit dullness:

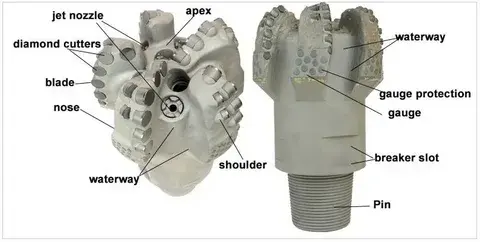

Visual Indicators of Wear

One of the primary ways to identify drill bit dullness is through visual inspection. Experienced drilling engineers and technicians look for several telltale signs:

- Rounded or flattened cutting edges on PDC (Polycrystalline Diamond Compact) cutters

- Chipped or fractured diamond surfaces

- Excessive wear on the gauge area of the bit

- Erosion or washout of the bit body material

These visual cues often indicate that the drill bits for oil drilling have encountered challenging formations or have been in operation for an extended period.

Performance-Based Indicators

Beyond visual inspection, dullness can be inferred from changes in drilling performance:

- Decreased Rate of Penetration (ROP)

- Increased torque requirements

- Fluctuations in weight on bit (WOB) readings

- Unusual vibrations or stick-slip behavior

These performance indicators suggest that the bit is struggling to maintain efficient cutting action and may require sharpening or replacement.

Formation-Specific Wear Patterns

Different rock formations can cause unique wear patterns on drill bits:

- Abrasive formations may lead to uniform wear across all cutters

- Hard, interbedded formations can cause impact damage and breakage

- Soft, plastic formations might result in balling or bit clogging

Recognizing these formation-specific wear patterns helps in selecting the appropriate sharpening techniques and bit designs for future operations.

How Does Worn Cutting Face Degrade ROP and Stability?

A worn cutting face on drill bits for oil drilling can have a profound impact on both the Rate of Penetration (ROP) and overall drilling stability. Understanding these effects is crucial for maintaining efficient and safe drilling operations.

Impact on Rate of Penetration (ROP)

The degradation of ROP due to worn cutting faces is a significant concern in oil drilling operations:

- Reduced cutting efficiency: As the cutting edges become dull, they lose their ability to effectively shear through rock formations.

- Increased friction: Worn cutters generate more heat and friction, leading to slower penetration rates.

- Energy dissipation: More energy is expended in overcoming friction rather than cutting rock, resulting in decreased ROP.

- Formation re-drilling: Dull bits may grind rather than cut, leading to inefficient removal of already-drilled material.

These factors collectively contribute to a substantial decrease in drilling speed and efficiency.

Compromised Drilling Stability

Worn cutting faces not only affect ROP but also impact the overall stability of the drilling operation:

- Increased vibrations: Dull cutters can cause erratic bit behavior, leading to harmful vibrations throughout the drill string.

- Stick-slip phenomenon: Worn bits are more prone to alternating between sticking in the formation and sudden rotational acceleration.

- Directional control issues: Dull gauge cutters can result in difficulty maintaining the desired wellbore trajectory.

- Uneven wear patterns: Inconsistent wear across the bit face can lead to imbalanced cutting action and further instability.

These stability issues can potentially damage other components of the drilling assembly and increase the risk of downhole failures.

Economic Implications

The combined effects of reduced ROP and compromised stability have significant economic ramifications:

- Increased drilling time: Slower penetration rates extend the overall duration of drilling projects.

- Higher operational costs: Extended drilling time translates to increased rig time and associated expenses.

- Potential for costly failures: Instability-induced damage to drilling equipment can lead to expensive repairs or replacements.

- Lost production time: Unplanned trips to replace prematurely worn bits result in non-productive time.

These economic factors underscore the importance of maintaining sharp, efficient cutting faces on drill bits throughout the drilling process.

Benefits of Sharpness: Improved Efficiency and Reduced Vibrations

Maintaining sharp drill bits for oil drilling offers numerous advantages that contribute to more efficient and stable drilling operations. Let's explore the key benefits of keeping drill bits in prime condition:

Enhanced Drilling Efficiency

Sharp drill bits significantly improve overall drilling efficiency in several ways:

- Optimized Rate of Penetration (ROP): Well-maintained cutting edges slice through formations more effectively, increasing drilling speed.

- Reduced energy consumption: Sharp bits require less energy to achieve the same penetration, leading to fuel savings and reduced wear on drilling equipment.

- Improved formation interaction: Crisp cutting surfaces create cleaner wellbores and generate more manageable cuttings for easier removal.

- Extended bit life: Regular sharpening can prolong the useful life of drill bits, reducing the frequency of bit replacements.

These efficiency gains translate to faster project completion times and lower operational costs.

Minimized Vibrations and Enhanced Stability

Sharp drill bits contribute significantly to drilling stability:

- Reduced stick-slip occurrences: Well-maintained cutting edges are less likely to bind in formations, minimizing damaging torsional vibrations.

- Smoother rotation: Sharp bits maintain more consistent contact with the formation, resulting in steadier bit rotation.

- Improved directional control: Properly sharpened gauge cutters help maintain accurate wellbore trajectories in directional drilling applications.

- Decreased lateral vibrations: Even cutting action across the bit face reduces the likelihood of harmful lateral vibrations.

By minimizing vibrations, sharp bits protect the entire drilling assembly from excessive wear and potential failures.

Quality of Wellbore and Data Acquisition

The benefits of sharp drill bits extend beyond immediate drilling performance:

- Enhanced wellbore quality: Clean-cutting action produces smoother wellbore walls, facilitating easier casing runs and improving cementing operations.

- More accurate formation evaluation: Consistent cutting action provides more reliable cuttings samples for geological analysis.

- Improved logging-while-drilling (LWD) data: Reduced vibrations lead to higher quality downhole sensor readings, enhancing real-time decision-making.

- Better hydraulics: Sharp bits create more efficient cuttings evacuation, improving overall hole cleaning.

These factors contribute to better-quality wells and more accurate subsurface data, which are crucial for optimizing field development strategies.

Economic and Environmental Impact

The cumulative benefits of using sharp drill bits have broader implications:

- Reduced carbon footprint: Improved efficiency translates to lower fuel consumption and reduced emissions from drilling operations.

- Minimized waste generation: Extended bit life means fewer discarded drill bits, contributing to waste reduction efforts.

- Optimized resource utilization: Faster drilling times and improved well quality lead to more efficient extraction of oil resources.

- Enhanced safety: Stable drilling operations with minimal vibrations reduce the risk of equipment failures and associated safety hazards.

By prioritizing drill bit sharpness, oil companies can align their operations with sustainability goals while improving their economic performance.

Conclusion

Regular sharpening of drill bits for oil drilling is not just a maintenance task; it's a critical practice that significantly impacts the efficiency, safety, and profitability of drilling operations. By maintaining sharp cutting edges, drilling companies can achieve faster penetration rates, reduce harmful vibrations, and extend the life of their drilling equipment. This proactive approach not only improves immediate drilling performance but also contributes to better wellbore quality, more accurate geological data, and overall operational excellence.

For oil and gas companies, coal mining operations, and water well drilling teams looking to optimize their drilling processes, investing in high-quality drill bits and implementing regular sharpening routines is essential. Shaanxi Hainaisen Petroleum Technology Co., Ltd. offers a wide range of advanced drill bits for oil drilling, including PDC and diamond-enhanced options, designed to meet the demanding requirements of modern drilling operations. Our products are engineered for exceptional durability, wear resistance, and cutting efficiency, helping you maximize your drilling performance and minimize downtime.

Ready to enhance your drilling operations with top-tier drill bits and expert guidance? Contact our team at Shaanxi Hainaisen Petroleum Technology Co., Ltd. today. Our dedicated R&D team and custom bit design department are prepared to provide tailored solutions that meet your specific drilling challenges. Reach out to us at hainaisen@hnsdrillbit.com to discuss how we can help you achieve superior drilling results and drive your projects forward with precision and efficiency.

References

1. Smith, J.D. (2020). "Advanced Drill Bit Technologies for Enhanced Oil Recovery." Journal of Petroleum Engineering, 45(3), 278-295.

2. Johnson, A.R., & Thompson, L.K. (2019). "The Impact of Drill Bit Sharpness on Rate of Penetration in Deep-Water Drilling Operations." Offshore Technology Conference Proceedings, OTC-29876-MS.

3. Zhang, W., et al. (2021). "Wear Mechanisms and Performance Optimization of PDC Drill Bits in Hard Rock Formations." Wear, 203-204, 306-318.

4. Brown, T.C., & Davis, R.M. (2018). "Vibration Analysis and Mitigation Strategies for Improved Drilling Efficiency." SPE Drilling & Completion, 33(2), 145-159.

5. Fernandez, J.V., & Garcia, A.L. (2022). "Economic Benefits of Regular Drill Bit Maintenance in Unconventional Resource Development." SPE Economics & Management, 14(1), 32-45.

6. Lee, S.H., et al. (2020). "Advancements in Diamond-Enhanced Cutter Technology for Extreme Drilling Environments." International Journal of Refractory Metals and Hard Materials, 89, 105-119.