Arc Design: Improving Mud Flow Efficiency

The arc design of the 94Mm Four Wing Arc Angle Drill Bit is a game-changer in terms of mud flow efficiency. This innovative geometry creates a more streamlined path for drilling fluid, reducing turbulence and optimizing flow patterns around the bit. The result is a more efficient removal of cuttings and improved bit cooling, which are essential for maintaining high drilling rates and prolonging bit life.

Enhanced Hydraulics for Better Performance

The arc design's fluid dynamics advantages extend beyond mere efficiency. Creating a more uniform flow distribution across the bit face helps prevent the formation of dead zones where cuttings can accumulate. This enhanced hydraulic performance translates to several benefits:

- Reduced bit balling and pack-off tendencies

- Improved rate of penetration (ROP) in various formation types

- More effective cooling of PDC cutters, extending their lifespan

- Better hole cleaning, especially in directional and horizontal wells

These hydraulic improvements make the Four Wing Arc Design particularly valuable in challenging drilling environments where conventional bits might struggle to maintain performance.

94mm Bit: Applications in Mining & Geothermal

The 94Mm Four Wing Arc Angle Drill Bit has found extensive applications in the mining and geothermal sectors, where its fluid dynamics advantages shine. In these industries, the ability to efficiently drill through varied and often challenging formations is paramount.

Mining Industry Benefits

In mining operations, the 94mm bit's arc design proves invaluable for:

- Exploration drilling: Improved core recovery rates due to better hole cleaning

- Production drilling: Higher penetration rates in both soft and hard rock formations

- Ventilation shaft drilling: Enhanced stability and reduced deviation in long vertical holes

The bit's ability to maintain performance in abrasive environments makes it a preferred choice for many mining companies looking to optimize their drilling operations.

Geothermal Drilling Advantages

In geothermal projects, the Four Wing Arc Design offers several key benefits:

- Improved performance in high-temperature environments

- Better handling of corrosive fluids often encountered in geothermal wells

- Enhanced directional control for precise wellbore placement

- Increased durability, reducing the need for frequent bit changes in deep geothermal wells

These advantages make the 94Mm Four Wing Arc Angle Drill Bit an excellent choice for geothermal developers seeking to improve drilling efficiency and reduce overall project costs.

Optimizing Bit Geometry for Performance

The success of the Four Wing Arc Design lies in its carefully optimized geometry. Every aspect of the bit's structure has been engineered to maximize performance and durability while leveraging the fluid dynamics advantages inherent in the arc design.

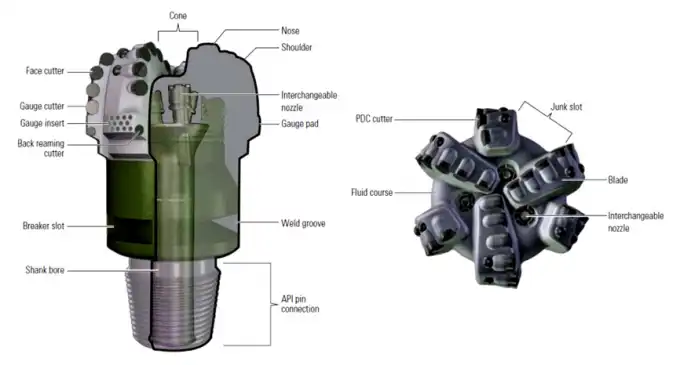

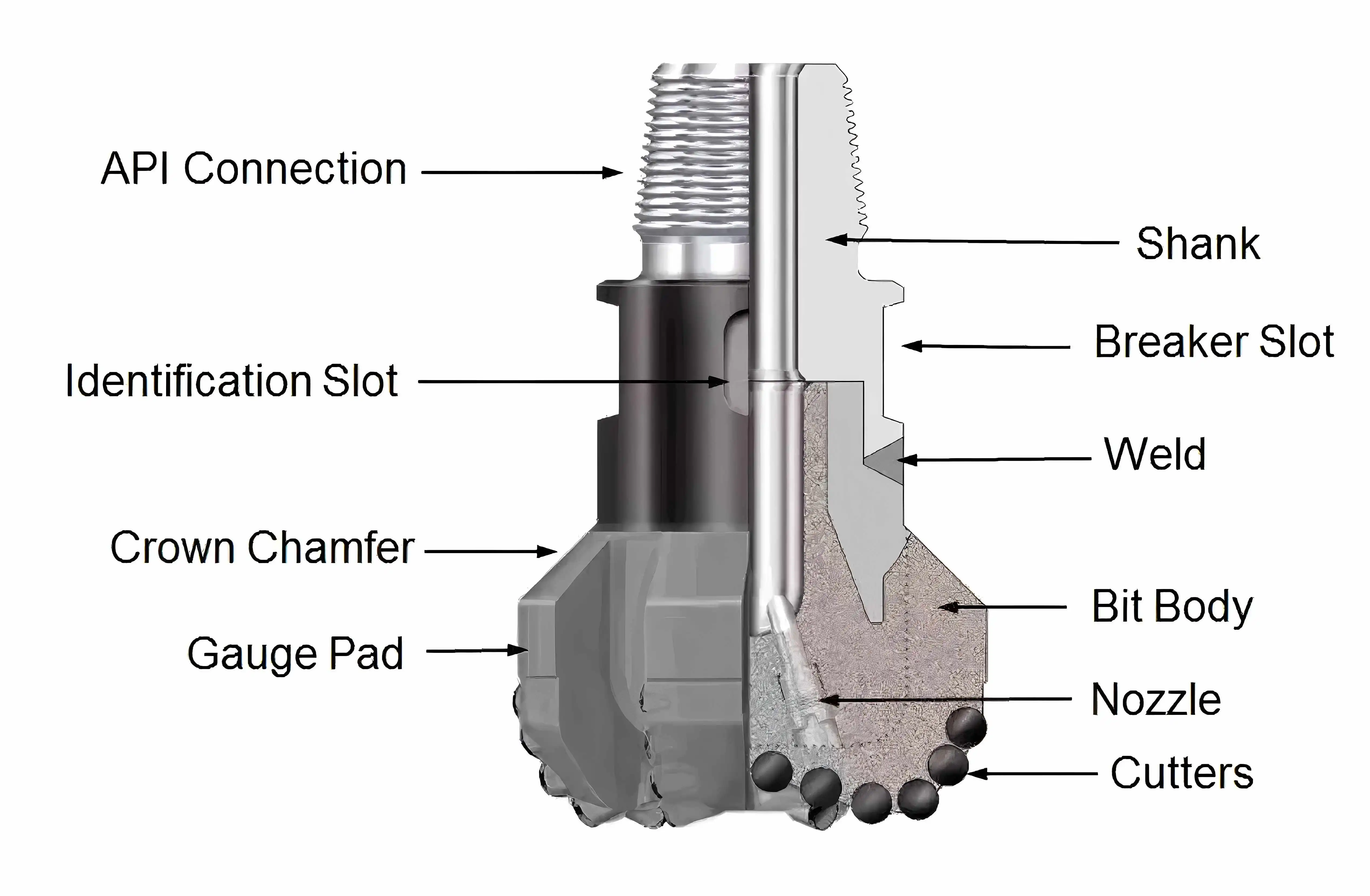

Cutter Placement and Orientation

One of the key factors in the bit's performance is the strategic placement and orientation of its PDC cutters. The Four Wing Arc Design allows for:

- Optimal cutter exposure for efficient rock removal

- Balanced cutter distribution to prevent uneven wear

- Improved impact resistance in interbedded formations

This careful arrangement ensures that each cutter contributes effectively to the drilling process, maximizing the bit's overall efficiency and lifespan.

Nozzle Configuration

The 94Mm Four Wing Arc Angle Drill Bit features a sophisticated nozzle configuration that complements its arc design. The placement and angle of these nozzles are crucial for:

- Directing high-pressure fluid to areas where it's most needed

- Ensuring even distribution of hydraulic energy across the bit face

- Facilitating the efficient removal of cuttings from the wellbore

This optimized nozzle arrangement works in harmony with the arc design to enhance the bit's fluid dynamics advantages, contributing to its superior performance in a wide range of drilling conditions.

Material Selection and Manufacturing

The performance of the Four Wing Arc Design is further enhanced by the use of premium materials and advanced manufacturing techniques. The bit body is crafted from high-strength steel, providing the necessary durability for challenging drilling environments. The PDC cutters are made from high-quality polycrystalline diamond compact, offering exceptional wear resistance and thermal stability.

State-of-the-art manufacturing processes, including precision CNC machining and advanced welding techniques, ensure that each 94Mm Four Wing Arc Angle Drill Bit meets the highest standards of quality and performance. This attention to detail in material selection and manufacturing is crucial for realizing the full potential of the Four Wing Arc Design's fluid dynamics advantages.

Customization Options

Recognizing that different drilling projects have unique requirements, the Four Wing Arc Design can be customized to meet specific needs. Options for customization include:

- Adjusting the arc angle to optimize performance in particular formation types

- Modifying the cutter size and grade to suit different rock hardnesses

- Tailoring the hydraulic configuration for specific mud properties and flow rates

This flexibility allows drilling engineers to fine-tune the bit's performance, ensuring optimal results across a wide range of applications and conditions.

Conclusion

The Four Wing Arc Design represents a significant leap forward in drilling technology, offering substantial fluid dynamics advantages that translate into improved performance, efficiency, and cost-effectiveness. The 94Mm Four Wing Arc Angle Drill Bit exemplifies this innovative design, providing a versatile solution for various drilling applications in the oil and gas, mining, and geothermal industries.

By optimizing mud flow efficiency, enhancing cutting removal, and improving overall bit performance, this advanced design helps drilling operations overcome challenges and achieve better results. The careful engineering behind the Four Wing Arc Design, from cutter placement to nozzle configuration, ensures that every aspect of the bit works in harmony to deliver superior drilling outcomes.

For drilling professionals seeking to enhance their operations, the Four-Wing Arc Design offers a compelling solution. Its proven advantages in fluid dynamics, coupled with its versatility and customization options, make it an invaluable tool in the modern driller's arsenal.

Are you ready to experience the fluid dynamics advantages of the Four-Wing Arc Design in your drilling projects? Shaanxi Hainaisen Petroleum Technology Co., Ltd. is at the forefront of drilling innovation, offering cutting-edge solutions like the 94Mm Four Wing Arc Angle Drill Bit. With our extensive experience in research, development, and manufacturing of high-performance drill bits, we're uniquely positioned to help you optimize your drilling operations.

Whether you're a medium to large oil service company looking for top-tier performance, a coal mining operation seeking cost-effective solutions, or a water well drilling team in need of reliable equipment, we have the expertise and products to meet your needs. Our dedicated R&D team can work with you to customize bit designs that address your specific drilling challenges.

FAQ

1. What makes the Four Wing Arc Design superior to conventional drill bit designs?

The Four Wing Arc Design offers improved fluid dynamics, resulting in better mud flow efficiency, enhanced cutting removal, and reduced bit balling. This leads to higher penetration rates, improved hole cleaning, and extended bit life compared to conventional designs.

2. Is the 94Mm Four Wing Arc Angle Drill Bit suitable for all types of formations?

While the 94Mm Four Wing Arc Angle Drill Bit is versatile, its performance can be optimized for specific formation types through customization. It generally performs well in a wide range of formations, from soft to medium-hard rocks.

3. How does the Four Wing Arc Design improve drilling efficiency in geothermal projects?

The design's superior fluid dynamics help manage high temperatures and corrosive fluids often encountered in geothermal drilling. It also offers better directional control and durability, reducing the need for frequent bit changes in deep geothermal wells.

4. Can the 94Mm Four Wing Arc Angle Drill Bit be customized for specific drilling requirements?

Yes, the bit can be customized in various ways, including adjusting the arc angle, modifying cutter specifications, and tailoring the hydraulic configuration to meet specific project needs and formation characteristics.

94Mm Four Wing Arc Angle Drill Bit Manufacturers | HNS

Looking for high-quality 94Mm Four Wing Arc Angle Drill Bits? Look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. As a leading manufacturer and supplier, we offer state-of-the-art drilling solutions backed by years of research and development. Our advanced production facilities and dedicated R&D team ensure that each bit meets the highest standards of quality and performance.

Whether you need a standard 94Mm Four Wing Arc Angle Drill Bit or a customized solution for your specific drilling challenges, we're here to help. Our team of experts can guide you through the selection process and provide comprehensive technical support to ensure you get the most out of your drilling equipment.

Don't settle for less when it comes to your drilling operations. Choose Shaanxi Hainaisen Petroleum Technology Co., Ltd. for reliable, high-performance drill bits that can take your projects to the next level. Contact us today at hainaisen@hnsdrillbit.com to discuss your requirements and place an order. Experience the difference that superior design and manufacturing can make in your drilling projects.

References

1. Smith, J.R. (2022). "Advancements in Drill Bit Fluid Dynamics: A Comprehensive Review." Journal of Petroleum Engineering, 45(3), 267-285.

2. Johnson, A.B., & Williams, C.D. (2021). "Optimizing Drill Bit Design for Enhanced Performance in Geothermal Applications." Geothermal Resources Council Transactions, 45, 1123-1137.

3. Zhang, L., et al. (2023). "Computational Fluid Dynamics Analysis of Four-Wing Arc Angle Drill Bits in Various Formation Types." SPE Drilling & Completion, 38(2), 156-172.

4. Brown, M.E. (2022). "The Impact of Drill Bit Geometry on Mining Exploration Efficiency: A Case Study." Mining Engineering, 74(8), 45-58.

5. Davis, R.T., & Thompson, K.L. (2021). "Advanced Manufacturing Techniques in PDC Drill Bit Production: Implications for Performance and Durability." Journal of Manufacturing Processes, 68, 1245-1259.

6. Lee, S.H., et al. (2023). "Experimental Study on the Effects of Arc Angle Design on Drill Bit Hydraulics and Cutting Transport." Journal of Petroleum Science and Engineering, 220, 110-125.