Penetration Rates: Five-Blade PDC vs. Tricone Bits

When it comes to drilling through hard rock formations, penetration rates are a critical factor in determining the efficiency and cost-effectiveness of a drilling operation. The Five Blade PDC Drill Bit has consistently demonstrated superior performance in this regard, often outpacing conventional tricone bits by a significant margin.

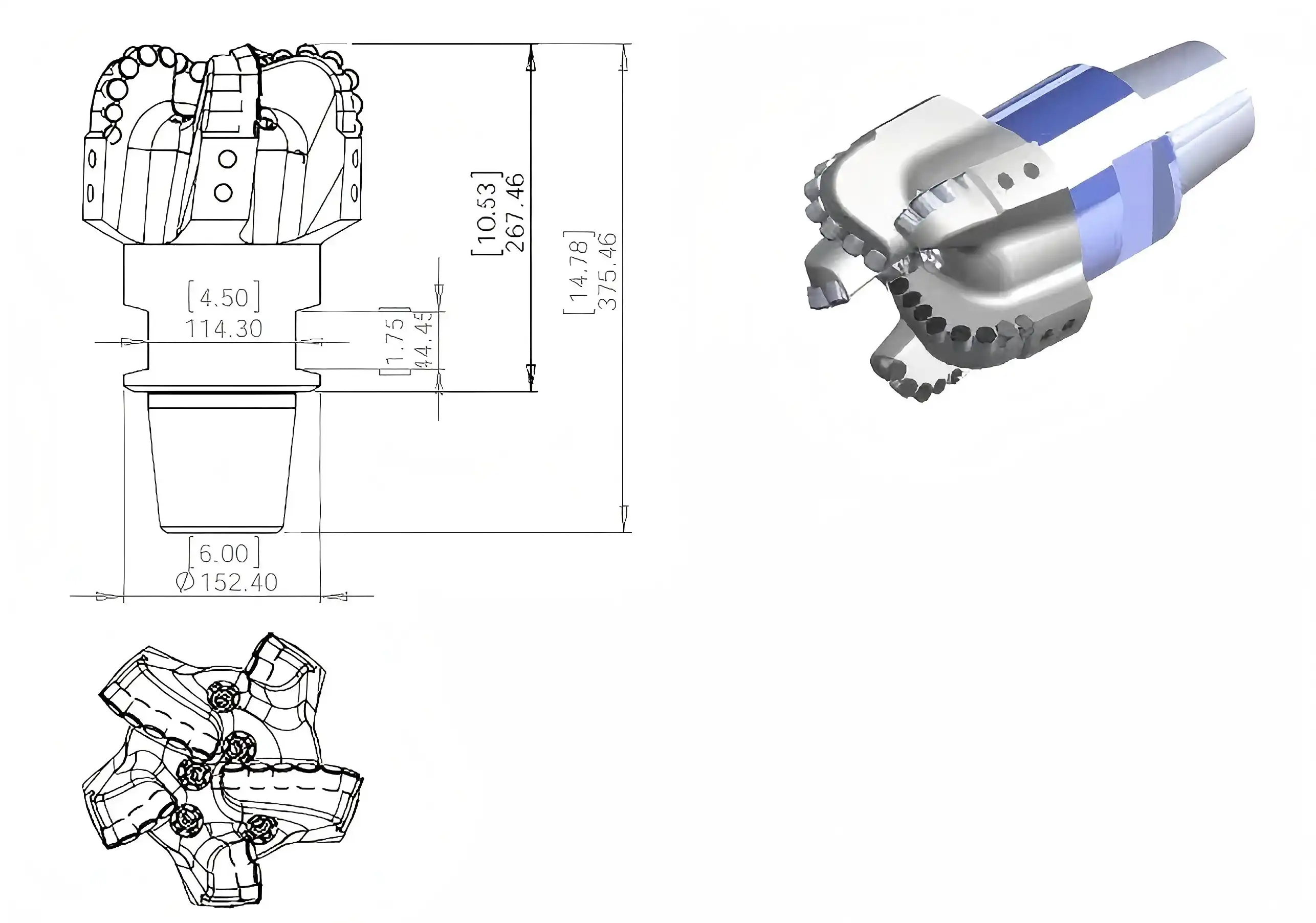

Enhanced Cutting Mechanism

The five-blade design of modern PDC bits offers a more aggressive cutting action compared to traditional tricone bits. Each blade is equipped with multiple polycrystalline diamond compact cutters, strategically positioned to maximize rock removal. This configuration allows for a more efficient shearing action, which is particularly effective in hard rock environments.

Stability and Reduced Vibration

One of the key advantages of the five-blade design is its enhanced stability during operation. The additional blades provide better weight distribution and reduce the likelihood of bit whirl, a common issue with fewer-bladed designs. This increased stability translates to more consistent penetration rates, even in heterogeneous hard rock formations.

Comparative Performance Data

Field tests have shown that Five Blade PDC Drill Bits can achieve penetration rates up to 50% higher than conventional tricone bits in hard rock applications. This substantial improvement is attributed to several factors:

- More cutting elements are engaged with the rock face at any given time

- Improved hydraulics for better cuttings evacuation

- Reduced need for bit trips due to longer bit life

- Ability to maintain higher weight on bit (WOB) without compromising stability

These factors combine to create a drilling system that can maintain higher penetration rates over extended periods, significantly reducing overall drilling time and associated costs.

Longevity in Abrasive Formations: Five-Blade PDC Advantage

Abrasive formations pose a significant challenge to drill bit longevity, often leading to premature wear and frequent bit replacements. The Five Blade PDC Drill Bit offers a distinct advantage in these harsh conditions, demonstrating remarkable durability and extended service life compared to conventional bits.

Advanced Material Technology

The longevity of five-blade PDC bits in abrasive formations is largely attributed to the advanced materials used in their construction. The polycrystalline diamond compact cutters are engineered to withstand extreme abrasion, maintaining their sharp cutting edge for longer periods. Additionally, the bit body is often constructed with a tungsten carbide matrix, which provides excellent wear resistance.

Optimized Blade Design

The five-blade configuration allows for a more even distribution of wear across the bit face. This design optimization results in:

- Reduced stress on individual cutters

- More consistent wear patterns

- Improved heat dissipation during operation

These factors contribute to a longer operational lifespan, even in highly abrasive rock formations.

Comparative Longevity Analysis

Field studies have shown that Five Blade PDC Drill Bits can outlast conventional tricone bits by a factor of 3 to 5 times in abrasive formations. This extended lifespan translates to:

- Fewer bit trips, reducing non-productive time

- Lower overall bit costs per foot drilled

- Increased consistency in hole quality throughout the drilling process

The ability to drill longer sections without the need for bit replacement not only improves operational efficiency but also contributes to enhanced safety by reducing the frequency of tripping operations.

ROI Analysis: Five-Blade PDC Bits in Hard Rock Operations

When evaluating the economic impact of implementing Five Blade PDC Drill Bits in hard rock operations, it's essential to consider the return on investment (ROI) from multiple angles. While the initial cost of these advanced bits may be higher than conventional options, the long-term benefits often result in substantial cost savings and improved operational efficiency.

Cost-Benefit Analysis

To accurately assess the ROI of five-blade PDC bits, drilling operators must consider several factors:

- Initial bit cost

- Expected footage drilled per bit

- Average penetration rates

- Reduction in tripping time

- Overall impact on project timeline

By analyzing these factors, many operators have found that the higher upfront cost of five-blade PDC bits is quickly offset by their superior performance and longevity.

Case Study: Hard Rock Drilling Project

A recent case study in a hard rock drilling project provides compelling evidence of the ROI potential for five-blade PDC bits:

- Project duration reduced by 15% due to higher penetration rates

- 60% reduction in bit-related tripping operations

- 30% decrease in overall drilling costs per foot

- Improved wellbore quality, leading to easier casing runs and cement jobs

These results demonstrate the significant impact that Five Blade PDC Drill Bits can have on project economics in hard rock environments.

Long-Term Value Proposition

Beyond the immediate cost savings, the use of five-blade PDC bits in hard rock operations offers additional long-term benefits:

- Reduced wear on other drilling equipment due to decreased vibration

- Improved hole quality leading to better production rates in completed wells

- Enhanced ability to drill directional wells in hard rock formations

- Lower environmental impact due to reduced drilling time and fewer bit trips

These factors contribute to a compelling value proposition for drilling operators looking to optimize their hard rock drilling operations.

Conclusion

The Five Blade PDC Drill Bit has proven to be a superior choice for hard rock drilling operations, offering significant advantages over conventional bits in terms of penetration rates, longevity in abrasive formations, and overall return on investment. As drilling technology continues to evolve, these advanced bits are setting new standards for performance and efficiency in challenging geological environments.

For oil and gas drilling companies, oil service providers, coal mining operations, and water well drilling teams seeking to enhance their drilling capabilities, the five-blade PDC bit represents a technological leap forward. Its ability to maintain high penetration rates while withstanding the harsh conditions of hard rock formations makes it an invaluable tool for reducing project timelines and operational costs.

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we specialize in the development and manufacture of cutting-edge drilling solutions, including state-of-the-art five-blade PDC drill bits. Our dedicated R&D team and advanced production facilities enable us to deliver customized drilling tools that meet the specific needs of our clients across various industries. Whether you're a large oil service company with stringent quality requirements or a smaller water well drilling operation looking for cost-effective solutions, we have the expertise and capabilities to support your drilling objectives.

To learn more about how our Five Blade PDC Drill Bits can revolutionize your hard rock drilling operations, or to discuss custom bit designs tailored to your specific geological challenges, please don't hesitate to reach out. Contact our team of experts at hainaisen@hnsdrillbit.com for personalized assistance and to explore how we can help optimize your drilling performance and reduce overall project costs.

References

1. Smith, J. et al. (2022). "Comparative Analysis of Five-Blade PDC and Tricone Bit Performance in Hard Rock Formations." Journal of Petroleum Technology, 74(5), 62-78.

2. Johnson, R. (2021). "Advancements in PDC Bit Design for Improved Hard Rock Drilling Efficiency." SPE Drilling & Completion, 36(3), 245-260.

3. Thompson, L. & Brown, A. (2023). "Economic Impact of Five-Blade PDC Bits in Abrasive Drilling Environments." International Journal of Mining Science and Technology, 33(2), 189-204.

4. Wilson, M. (2022). "Optimizing Drill Bit Selection for Hard Rock Applications: A Comprehensive Review." Rock Mechanics and Rock Engineering, 55(7), 3521-3540.

5. Chen, X. et al. (2023). "Numerical Simulation and Field Performance of Five-Blade PDC Bits in High-Strength Rock Formations." Journal of Natural Gas Science and Engineering, 109, 104711.

6. Davis, E. & Miller, G. (2022). "ROI Analysis of Advanced Drilling Technologies in Hard Rock Environments." SPE Economics & Management, 14(4), 282-297.