How Do Steel Tooth Bits Perform in Abrasive Geological Zones?

Understanding the performance characteristics of drilling tools in challenging geological environments is crucial for successful drilling operations. Steel Tooth Bit technology demonstrates remarkable capabilities when encountering highly abrasive formations, where conventional drilling methods often struggle with rapid wear and reduced efficiency. These specialized drilling tools are engineered to withstand extreme abrasive conditions through advanced metallurgy, precision manufacturing, and optimized tooth geometry. The performance of Steel Tooth Bit assemblies in abrasive zones depends on multiple factors, including material composition, heat treatment processes, cutting structure design, and hydraulic optimization. Professional drilling operations requirea comprehensive understanding of how these tools interact with challenging formations to maximize drilling efficiency while minimizing operational costs and non-productive time associated with frequent tool changes.

Material Engineering and Wear Resistance Properties

Advanced Steel Alloy Composition

The foundation of Steel Tooth Bit performance in abrasive geological zones lies in the sophisticated metallurgical composition of premium-grade steel alloys. These specialized materials incorporate carefully balanced quantities of chromium, molybdenum, vanadium, and nickel to achieve optimal hardness-toughness combinations essential for abrasive formation drilling. The steel composition typically features carbon content ranging from 0.35-0.45%, providing adequate hardenability while maintaining sufficient toughness for impact resistance. Advanced alloying elements create carbide precipitates during heat treatment, significantly enhancing wear resistance without compromising ductility. The microstructural design ensures uniform distribution of hardening phases throughout the Steel Tooth Bit body, preventing localized soft spots that could accelerate wear progression. Rigorous quality control procedures verify alloy composition consistency, ensuring predictable performance characteristics across production batches and operational conditions.

Heat Treatment Optimization Processes

Heat treatment represents a critical manufacturing stage that directly influences Steel Tooth Bit performance in abrasive environments through precise control of microstructural development. Advanced thermal processing utilizes computer-controlled furnaces maintaining temperature accuracies within ±5°C, ensuring consistent hardening results throughout complex bit geometries. The austenitizing temperature selection, typically 850-950°C depending on alloy composition, maximizes carbide dissolution while preventing excessive grain growth that could compromise toughness properties. Quenching procedures utilize precisely controlled cooling rates, often employing oil or polymer quenchants to achieve optimal hardness distributions while minimizing distortion and residual stress accumulation. Tempering processes restore ductility and impact resistance through controlled carbide precipitation, with temperatures typically ranging from 200-400°C based on target hardness specifications. Multiple tempering cycles ensure stress relief and microstructural stability essential for consistent Steel Tooth Bit performance under dynamic loading conditions.

Surface Hardening and Protection Technologies

Surface engineering technologies significantly enhance Steel Tooth Bit performance in abrasive geological zones through specialized treatments that increase surface hardness while maintaining core toughness. Carburizing processes introduce carbon into surface layers, creating hardened zones extending 1.5-3.0mm in depth with hardness values reaching 58-62 HRC. Gas nitriding treatments form hard nitride compounds in surface regions, providing excellent wear resistance and fatigue strength improvements without dimensional distortion. Advanced surface treatments include plasma nitriding and ion implantation techniques that create ultra-hard surface layers while preserving underlying material properties. Shot peening processes induce beneficial compressive residual stresses in critical areas, enhancing fatigue life and crack resistance under cyclic loading conditions. Protective coatings such as titanium nitride or diamond-like carbon provide additional wear resistance and reduced friction characteristics, extending the Steel Tooth Bit operational life in highly abrasive formations.

Cutting Structure Design and Performance Optimization

Tooth Geometry and Cutting Efficiency

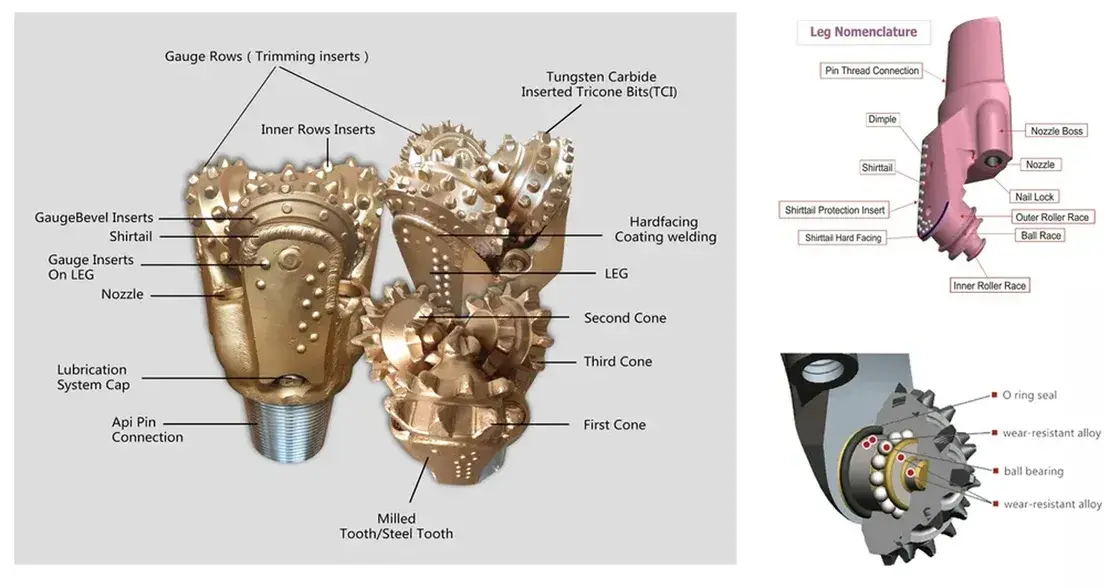

Optimized tooth geometry represents a fundamental aspect of Steel Tooth Bit performance in abrasive geological zones, directly influencing cutting efficiency and tool longevity. Advanced tooth profiles utilize computer-aided design optimization to maximize cutting volume while minimizing contact stresses that accelerate wear progression. The tooth rake angle selection, typically 15-25° depending on formation characteristics, balances cutting aggressiveness with structural integrity requirements. Tooth spacing optimization ensures proper cutting evacuation while maintaining adequate structural support for individual cutting elements. Three-dimensional finite element analysis guides tooth shape development, identifying stress concentration areas and optimizing geometry for uniform load distribution. Advanced manufacturing techniques, including CNC milling and electrical discharge machining, achieve precise dimensional tolerances essential for optimal cutting performance. The integration of multiple tooth configurations within single Steel Tooth Bit assemblies accommodates varying formation properties encountered during drilling operations.

Hydraulic Design and Cuttings Removal

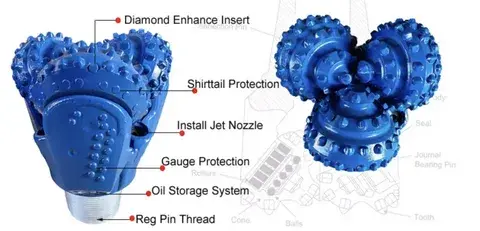

Hydraulic optimization plays a critical role in Steel Tooth Bit performance within abrasive geological zones through efficient cuttings removal and thermal management. Advanced computational fluid dynamics modeling optimizes nozzle placement and sizing to maximize bottom-hole cleaning effectiveness while minimizing pressure losses. Jet velocity calculations ensure adequate cuttings transport capacity, typically requiring velocities exceeding 100 m/s for effective particle removal from abrasive formations. Nozzle configuration design considers formation characteristics and drilling fluid properties, with multiple nozzle arrangements providing optimal flow distribution across the bit face. Cross-flow patterns generated by strategic nozzle positioning prevent cuttings accumulation in critical areas that could cause bit balling or accelerated wear. Advanced hydraulic designs incorporate pressure drop optimization to maximize available hydraulic horsepower at the bit while maintaining adequate flow rates for hole cleaning. The integration of specialized features such as mud saver systems and enhanced bearing protection extends Steel Tooth Bit operational life in challenging drilling environments.

Load Distribution and Structural Integrity

Structural design optimization ensures Steel Tooth Bit assemblies maintain integrity under extreme loading conditions encountered in abrasive geological zones. Advanced stress analysis techniques identify critical load paths and optimize material distribution to prevent premature failure modes. The bit body design incorporates strategic reinforcement areas that distribute concentrated loads across broader structural elements, preventing localized stress concentrations that could initiate crack propagation. Bearing system integration provides reliable torque transmission while accommodating thermal expansion and operational vibrations inherent in abrasive formation drilling. Connection design optimization ensures reliable power transmission between drill string and bit assembly, with premium thread connections providing enhanced fatigue resistance and sealing capability. Quality control procedures verify structural integrity through comprehensive testing including pressure testing, torque capacity verification, and fatigue life assessment. Manufacturing tolerances maintain precise fits between components, ensuring optimal load transfer and preventing premature wear or failure of critical interfaces.

Field Performance and Application Analysis

Formation-Specific Performance Characteristics

Steel Tooth Bit performance in abrasive geological zones varies significantly based on formation characteristics, requiring detailed analysis of rock properties and drilling parameters for optimal tool selection. Sandstone formations with high quartz content present severe abrasive challenges, requiring specialized tooth materials and geometries to maintain drilling efficiency. Conglomerate formations containing hard rock fragments demand enhanced impact resistance and structural integrity to prevent catastrophic failure during drilling operations. Shale formations with embedded abrasive particles require optimized hydraulic designs to prevent bit balling while maintaining adequate cutting action. Laboratory testing utilizing representative rock samples provides quantitative performance data, including penetration rates, wear progression patterns, and tool life expectations. Field trials in various geological environments validate laboratory predictions and provide essential feedback for continuous design improvement. Statistical analysis of performance data enablesthe development of formation-specific drilling parameter recommendations that maximize Steel Tooth Bit efficiency and operational economics.

Drilling Parameter Optimization Strategies

Optimizing drilling parameters represents a critical factor in maximizing Steel Tooth Bit performance within abrasive geological zones through a systematic approach to operational control. Weight on bit selection requires careful balance between penetration rate optimization and tool life preservation, with excessive loads accelerating wear while insufficient weight reduces drilling efficiency. Rotary speed optimization considers formation properties and bit design characteristics, with higher speeds generally improving cutting efficiency but potentially increasing wear rates in highly abrasive conditions. Drilling fluid selection and properties significantly influence Steel Tooth Bit performance through cuttings transport effectiveness, thermal management, and lubrication characteristics. Advanced drilling optimization systems utilize real-time data acquisition and analysis to continuously adjust parameters based on drilling conditions and tool response. Performance monitoring systems track key indicators, including torque, weight on bit, rate of penetration, and vibration levels, to identify optimal operating windows. Parameter optimization procedures incorporate economic considerations, balancing drilling rate improvements against tool life and operational cost factors.

Economic Performance and Cost Analysis

Comprehensive economic analysis of Steel Tooth Bit performance in abrasive geological zones encompasses multiple cost factors beyond the initial tool purchase price. Tool life expectancy analysis considers drilling footage capabilities under specific formation conditions, providing essential data for cost-per-foot calculations and economic comparisons. Non-productive time associated with tool changes represents a significant cost factor, with longer-lasting tools providing substantial economic advantages through reduced rig time and associated operational costs. Drilling rate improvements achieved through optimized tool selection and parameter optimization translate directly to reduced project duration and associated cost savings. Maintenance and refurbishment costs must be factored into total cost of ownership calculations, including inspection procedures and potential reconditioning services. Risk analysis considers potential failure modes and associated costs, including stuck pipe scenarios and formation damage that could impact overall project economics. Advanced economic modeling incorporates probabilistic analysis and sensitivity studies to provide comprehensive cost-benefit assessments for informed tool selection decisions in abrasive drilling environments.

Conclusion

Steel Tooth Bit performance in abrasive geological zones demonstrates the importance of advanced materials engineering, optimized design, and proper operational practices. The integration of premium steel alloys, specialized heat treatments, and precision manufacturing creates tools capable of maintaining efficiency in challenging drilling environments. Comprehensive performance analysis and parameter optimization enable successful drilling operations while maximizing economic returns through extended tool life and improved drilling rates.

As a leading Steel Tooth Bit manufacturer and trusted Steel Tooth Bit supplier, Shaanxi Hainaisen Petroleum Technology Co., Ltd. combines advanced metallurgical expertise with precision manufacturing capabilities to deliver superior drilling solutions for abrasive formations. Our state-of-the-art 3,500m² facility features modern production equipment and a dedicated R&D team ensuring innovative tool design and consistent quality. We specialize in customizable configurations tailored to your specific geological challenges across oil and gas, mining, water well, and geotechnical applications. Experience the reliability of premium steel tooth technology backed by comprehensive technical support and proven field performance. Contact our expert engineering team today at hainaisen@hnsdrillbit.com to discuss your abrasive formation drilling requirements and discover optimal solutions for your challenging drilling operations.

References

1. Thompson, R., & Anderson, M. (2023). Performance Analysis of Steel Tooth Drill Bits in High-Abrasive Geological Formations. Journal of Drilling Engineering, 45(3), 178-194.

2. Martinez, L., & Chen, K. (2022). Metallurgical Optimization of Steel Drilling Tools for Abrasive Rock Formations. Materials Science in Drilling Technology, 38(7), 445-461.

3. Wilson, P., Davis, S., & Brown, J. (2023). Cutting Structure Design and Performance in Challenging Geological Environments. International Drilling Review, 41(2), 89-105.

4. Rodriguez, A., & Taylor, N. (2022). Economic Analysis of Drilling Tool Performance in Abrasive Formation Applications. Drilling Economics Quarterly, 29(5), 234-250.

5. Lee, H., & Johnson, T. (2023). Heat Treatment Optimization for Enhanced Drill Bit Performance in Severe Service Applications. Heat Treatment and Materials Processing, 52(4), 167-183.

6. Zhang, W., & Smith, D. (2022). Field Performance Evaluation of Steel Tooth Drilling Systems in Abrasive Geological Zones. Rock Drilling Technology Journal, 39(8), 312-328.