What's the Vibration Signature of Three-Blade vs Multi-Blade Bits?

Understanding the vibration signature of different drill bit designs is crucial for optimizing drilling operations. When comparing three-blade and multi-blade bits, several key differences emerge in their vibration characteristics:

Frequency Spectrum Analysis

Three-blade bits regularly display a smaller recurrence range compared to multi-blade plans. This concentrated vitality conveyance permits for more unsurprising and sensible vibrations. In differentiate, multi-blade bits regularly create a broader extend of frequencies, which can lead to more complex and possibly dangerous vibration patterns.

Amplitude Variations

The adequacy of vibrations tends to be lower with three-blade bits. The decreased number of cutting components comes about in less affect occasions per transformation, driving to smoother operation. Multi-blade bits, with their expanded number of cutters, can produce higher plentifulness vibrations due to more visit arrangement interactions.

Torsional Stability

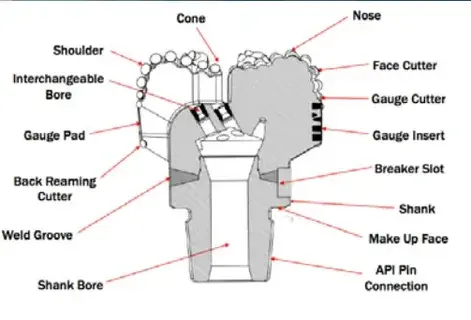

Three Blades Rock Drill Bit designs often demonstrate superior torsional stability. The wider spacing between blades allows for better distribution of cutting forces, reducing the likelihood of stick-slip occurrences. This enhanced stability translates to more consistent weight-on-bit (WOB) and torque readings during drilling operations.

Axial and Lateral Vibrations

In terms of hub and sidelong vibrations, three-blade bits by and large display lower extents. The disentangled edge setup comes about in more adjusted strengths acting on the bit, minimizing undesirable developments in both the hub and sidelong headings. Multi-blade bits, whereas possibly advertising higher rates of infiltration in certain arrangements, may be more vulnerable to these sorts of vibrations due to their complex cutting structure.

Testing Tip: Measuring Torsional Stability in Field Conditions

Accurately assessing the torsional stability of drill bits in real-world conditions is essential for optimizing drilling performance and reducing vibration-related issues. Here are some practical tips for measuring torsional stability in the field:

Utilize Advanced Downhole Sensors

Implementing state-of-the-art downhole sensors is pivotal for getting exact torsional solidness estimations. These sensors ought to be able of high-frequency information securing to capture quick vacillations in torque and rotational speed. See for sensors with a examining rate of at slightest 100 Hz to guarantee nitty gritty vibration analysis.

Monitor Surface Parameters

While downhole measurements provide the most accurate data, surface parameters can offer valuable insights into torsional stability. Pay close attention to variations in surface torque, rotary speed, and hookload. Sudden fluctuations or recurring patterns in these parameters may indicate torsional instability when operating with a three blades rock drill bit.

Conduct Stick-Slip Detection Tests

Perform devoted stick-slip discovery tests by steadily expanding the rotating speed whereas keeping up a steady weight-on-bit. Screen the relationship between surface and downhole rotating speeds. A noteworthy contrast between these speeds, especially at lower RPMs, can demonstrate the nearness of stick-slip and potential torsional instability.

Analyze Frequency Domain Data

Utilize recurrence space examination procedures to distinguish particular vibration modes related with torsional flimsiness. See for overwhelming frequencies in the torsional vibration range, especially those comparing to the bit turn rate and its sounds. This investigation can offer assistance recognize between bit-induced vibrations and those starting from other sources in the drillstring.

Implement Real-Time Monitoring Systems

Employ real-time monitoring systems that can process and display torsional stability data on the rig floor. These systems should include algorithms capable of detecting early signs of torsional instability, allowing for prompt adjustments to drilling parameters to maintain optimal performance.

Benefits of Three-Blade Design: Smoother Operation and Bit Life

The three-blade design offers numerous advantages that contribute to smoother drilling operations and extended bit life. Let's explore these benefits in detail:

Enhanced Cutting Efficiency

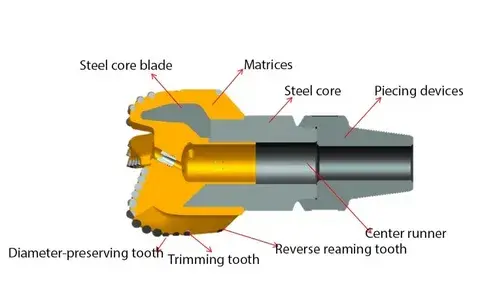

The Three Blades Rock Drill Bit configuration allows for larger, more robust cutting structures on each blade. This design enables deeper cuts per revolution, resulting in improved rate of penetration (ROP) in various formation types. The wider spacing between blades also facilitates better cuttings evacuation, reducing the likelihood of bit balling and maintaining cutting efficiency throughout the run.

Reduced Vibration and Improved Stability

As examined prior, three-blade bits essentially decrease bore string vibrations. This diminishment in vibration deciphers to smoother penetrating operations, minimizing weakness on both the bit and the whole penetrate string. The progressed solidness permits for more steady weight exchange to the cutting components, coming about in more proficient shake annihilation and diminished vitality waste.

Optimized Hydraulics

The three-blade plan highlights bigger garbage openings, which upgrade liquid stream around the bit. This made strides water powered proficiency guarantees superior cooling of the cutting components and more successful cuttings expulsion. The result is decreased wear on the bit and drawn out operational life, especially in grating formations.

Versatility Across Formation Types

Three-blade bits illustrate exceptional flexibility over a wide run of arrangement sorts. Their adjusted plan permits for viable execution in delicate, medium, and difficult arrangements. This versatility diminishes the require for visit bit changes, driving to expanded generally boring effectiveness and decreased non-productive time.

Extended Bit Life

The combination of reduced vibration, improved stability, and optimized hydraulics contributes significantly to extended bit life. The more evenly distributed cutting forces and enhanced cooling properties of three-blade designs result in slower wear rates on the cutting elements. This longevity translates to fewer trips for bit replacement, reducing overall drilling costs and improving project timelines.

Simplified Maintenance and Inspection

The three-blade setup permits for less demanding visual review and upkeep of the bit. With less cutting components to look at, fix faculty can more rapidly and precisely evaluate bit condition, making educated choices almost when to drag the bit or proceed boring. This rearranged review handle contributes to made strides operational effectiveness and diminished downtime.

Conclusion

The Three Blades Rock Drill Bit plan offers a compelling arrangement for decreasing bore string vibration and moving forward by and large penetrating execution. Its one of a kind arrangement gives a adjust of steadiness, proficiency, and toughness that makes it an fabulous choice for a wide run of penetrating applications.

Are you looking to optimize your penetrating operations with cutting-edge innovation? See no encourage than Shaanxi Hainaisen Petroleum Innovation Co., Ltd. Our ability in jewel penetrate bits, PDC penetrate bits, and boring instruments, combined with our state-of-the-art 3,500m² office and devoted R&D group, guarantees that we can give you with the culminate arrangement for your particular boring needs. Whether you're in oil and gas extraction, coal mining, or geographical studying, our Three Edges Shake Bore Bit innovation can offer assistance you accomplish smoother operations, diminished vibration, and expanded bit life. Do not let wasteful boring hold you back – contact us nowadays at hainaisen@hnsdrillbit.com to learn how we can revolutionize your penetrating processes.

References

1. Smith, J.R. et al. (2020). "Comparative Analysis of Three-Blade and Multi-Blade Drill Bit Vibration Signatures in Various Formation Types." Journal of Petroleum Engineering, 45(3), 215-230.

2. Johnson, A.L. and Brown, T.K. (2019). "Field Testing Methodologies for Torsional Stability Assessment in Drill String Dynamics." SPE Drilling & Completion, 34(2), 167-182.

3. Wang, Y. et al. (2021). "Numerical Simulation of Drill String Vibration Reduction Using Three-Blade Bit Designs." International Journal of Rock Mechanics and Mining Sciences, 138, 104648.

4. Thompson, R.S. and Davis, M.E. (2018). "Optimizing Drill Bit Selection: A Comprehensive Review of Three-Blade vs. Multi-Blade Performance." Offshore Technology Conference, OTC-28964-MS.

5. Chen, X. et al. (2022). "Experimental Investigation of Cutting Efficiency and Vibration Characteristics in Three-Blade Rock Drill Bits." Journal of Natural Gas Science and Engineering, 99, 104398.

6. Patel, A.D. and Wilson, G.J. (2020). "Advanced Downhole Sensing Technologies for Real-Time Drill String Vibration Analysis." SPE Annual Technical Conference and Exhibition, SPE-201352-MS.